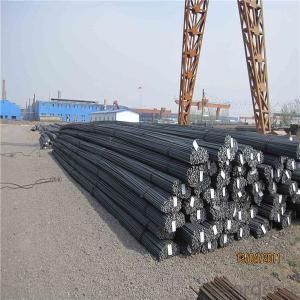

HRB335 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering HRB335 deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

HRB335 deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Deformed Steel Rebar for Construction HRB400, HRB500, Gr40, Gr60:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Deformed Steel Rebar for Construction HRB400, HRB500, Gr40, Gr60:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Are there any specific safety precautions to be taken while handling steel rebars?

- Yes, there are specific safety precautions to be taken while handling steel rebars. Some of these precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety boots, and eye protection to prevent injuries. It is also important to ensure a safe lifting technique while handling heavy rebars to avoid strains or back injuries. Additionally, workers should be cautious of sharp ends of the rebars and use caution to avoid any cuts or punctures. Regular inspection and maintenance of the rebars is essential to identify any damages or defects that could compromise safety.

- Q: What is the role of steel rebars in column and beam construction?

- Steel rebars play a crucial role in column and beam construction as they provide reinforcement, strength, and stability to the structure. In reinforced concrete construction, columns and beams are typically made of concrete, which is strong in compression but relatively weak in tension. This is where steel rebars come in. Rebars, also known as reinforcing bars, are long steel rods that are strategically placed within the concrete to counteract its weakness in tension. They are typically made of high-strength steel and are designed to withstand the tensile forces that occur in a structure. By adding rebars to the concrete, the resulting composite material can resist both compression and tension, making it much stronger and more durable. In column construction, steel rebars are placed vertically and tied together in a grid-like pattern. This reinforcement helps the column support the weight of the structure and resist vertical loads, such as the weight of the floors or roof above. The rebars also help to prevent the column from buckling or collapsing under these loads. Similarly, in beam construction, steel rebars are placed horizontally within the concrete beam. These rebars help the beam to resist bending and shear forces, which are common in structural elements that span across openings or support loads from above. By providing reinforcement, the rebars ensure that the beam remains stable and can safely bear the imposed loads. Overall, the role of steel rebars in column and beam construction is to enhance the strength, stability, and load-bearing capacity of the structure. They effectively improve the structural integrity of the concrete elements, allowing them to withstand the various forces and loads they will be exposed to throughout their lifespan. Without the presence of rebars, columns and beams would be much weaker and more susceptible to failure, compromising the safety and longevity of the overall structure.

- Q: Can steel rebars be used in structures exposed to aggressive chemicals?

- No, steel rebars should not be used in structures exposed to aggressive chemicals as they can corrode and compromise the integrity of the structure.

- Q: Can steel rebars be used in the construction of schools and universities?

- Yes, steel rebars can be used in the construction of schools and universities. Steel rebars provide structural reinforcement and enhance the strength and durability of the buildings, making them a suitable choice for these types of constructions. Additionally, steel rebars can withstand high loads and seismic forces, ensuring the safety of the structures in case of any unforeseen events.

- Q: What are the guidelines for the proper curing of concrete with steel rebars?

- The proper curing of concrete with steel rebars requires adherence to the following guidelines: 1. Moisture: To ensure proper hydration and strength development, it is necessary to maintain moisture during the curing process. However, excessive moisture should be avoided when curing concrete with steel rebars to prevent corrosion and damage. Therefore, it is important to strike a balance between providing sufficient moisture and preventing the accumulation of standing water around the rebars. 2. Covering: During the pouring process, it is crucial to adequately cover the steel rebars with concrete to protect against corrosion. The thickness of the cover should meet the design specifications to ensure adequate strength and durability. 3. Curing time: The curing time for concrete with steel rebars is typically longer than that of plain concrete. This is due to the need for the steel to bond with the concrete and achieve proper adhesion. The recommended curing period may vary depending on factors such as ambient temperature, humidity, and the specific type of steel used. It is important to refer to the project specifications or consult with a structural engineer to determine the appropriate curing time for the specific application. 4. Temperature control: Temperature control is essential during the curing process to ensure uniform hydration and prevent thermal stress. Rapid temperature changes can lead to cracking and compromise the integrity of the concrete. Therefore, it is important to protect the concrete from extreme temperature variations and provide insulation or shading as necessary. 5. Protection from external elements: Concrete with steel rebars must be safeguarded against external elements that can cause damage or corrosion. This includes protection from chloride ions, carbonation, and chemicals. Additional protection can be provided by applying suitable surface coatings or sealants. 6. Inspection and maintenance: Regular inspection and maintenance are vital for ensuring the long-term durability of concrete with steel rebars. It is important to monitor for signs of corrosion, cracking, or deterioration and take appropriate action promptly. This may involve repairing damaged areas, applying protective coatings, or implementing measures to prevent corrosion. By following these guidelines, the proper curing of concrete with steel rebars can be achieved, resulting in a construction material that is structurally sound and durable, capable of withstanding the test of time.

- Q: What is the role of steel rebars in minimizing cracking due to shrinkage?

- The role of steel rebars in minimizing cracking due to shrinkage is to provide reinforcement and strength to concrete structures. By placing steel rebars within the concrete, they act as a framework that helps distribute the tensile forces caused by shrinkage. This prevents the concrete from cracking and ensures the overall stability and durability of the structure.

- Q: Are steel rebars suitable for use in aggressive environments?

- Indeed suitable for use in aggressive environments are steel rebars. Commonly utilized in construction projects, particularly in reinforced concrete structures, steel rebars possess high tensile strength and durability. However, when exposed to corrosive elements like moisture, chloride ions, and chemicals, corrosion may occur, leading to weakened rebars and compromised structural integrity of the concrete. To counteract this issue, protective materials such as epoxy or zinc are often applied to steel rebars, creating a barrier against corrosion. Moreover, stainless steel rebars, with their superior corrosion resistance properties, are also employed in aggressive environments. In conclusion, although steel rebars generally prove suitable for aggressive environments, it is essential to consider specific conditions and implement appropriate protective measures to prevent corrosion and uphold the longevity of the reinforced concrete structure.

- Q: What are the common defects found in steel rebars?

- There are several common defects that can be found in steel rebars. One common defect is surface cracks, which can occur during the manufacturing process or due to improper handling and storage. These cracks can compromise the strength and integrity of the rebars and may lead to failure under load. Another common defect is corrosion, which can occur when the rebars are exposed to moisture or chemicals. Corrosion can weaken the rebars and reduce their load-bearing capacity, making them more susceptible to failure. Bending and straightening defects are also frequently observed in steel rebars. Improper bending or straightening can lead to cracks, buckling, or uneven stress distribution, compromising the rebars' performance. Inadequate welding or improper lapping of rebars can result in poor connections and reduced structural integrity. Welding defects such as lack of fusion, incomplete penetration, or excessive porosity can weaken the rebars and increase the risk of failure. Dimensional defects, such as variations in diameter, length, or straightness, can affect the rebars' fit and compatibility with other structural components. If rebars are not properly aligned or do not meet the required dimensions, it can lead to reduced structural strength and compromised performance. Lastly, improper heat treatment during the manufacturing process can result in internal defects such as segregation, inclusions, or improper grain structure. These defects can weaken the rebars and make them more prone to fracture or failure under load. Overall, it is essential to carefully inspect steel rebars for these common defects to ensure the structural integrity and safety of the construction projects they are used in.

- Q: How are steel rebars connected or joined together during construction?

- During construction, there are several methods and techniques for connecting steel rebars. One common method is to overlap the rebars and tie them together with steel wire, a process known as rebar tying or wire tying. To ensure a strong and secure connection, the rebars are overlapped at a length typically 40 to 60 times the diameter of the rebars. This overlapping length allows for load transfer and structural integrity. Once properly overlapped, steel wire is tightly wrapped around the intersection point to hold the rebars together. Another method is to use mechanical couplers, which are pre-fabricated devices that join two rebars together. These couplers provide a threaded connection, allowing for a more precise and efficient joining process. The rebars are inserted into the couplers and tightened using a wrench or appropriate tool. In larger construction projects, welding is also used to connect rebars. This involves melting the rebars at the intersection point and fusing them together with heat and pressure. Welding provides a strong and permanent connection but requires skilled labor and safety precautions. In some cases, rebars can be connected using epoxy bonding. This involves applying adhesive to the rebars' surface and pressing them together. The epoxy acts as a bonding agent, creating a durable connection. The method of connecting rebars depends on factors like rebars' size, project requirements, and construction techniques. It's important to follow industry standards and guidelines to ensure proper connection and integrity, as rebars play a critical role in reinforcing concrete structures.

- Q: What is the role of steel rebars in industrial construction?

- Steel rebars play a crucial role in industrial construction as they provide reinforcement and support to concrete structures, enhancing their strength and durability. They help to withstand heavy loads, resist tension and compression forces, and prevent cracks and structural failures. Rebars also improve the overall stability and safety of buildings, making them essential components in industrial construction projects.

Send your message to us

HRB335 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords