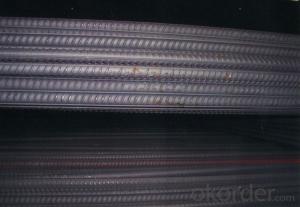

HRB335 small hot rolled deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

REINFORCING DEFORMED STEEL BAR

ACORDING TO ASTM/BS/FEE/ EXTC....

LENGTH:ANY LENGTH

PLEASE SEND US YOUR REQUEST WITH FULL DETAILS FOR BEST OFFER

REINFORCING DEFORMED STEEL BAR

ACORDING TO ASTM/BS/FEE/ EXTC....

LENGTH:ANY LENGTH

Specifications

Certificates: CE & ISO9001:2000

Material: hrhrb400 ,hrb500, BS4449, ASTM A615, SD400

length:6-12

Size: 6mm-40mm

Product Advantages:

OKorder's Hot Rolled Carbon Steel Deformed Bar 16-25mm with High Quality are durable, strong.packed and suitable for construction

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB335 HRB400 BS4449 Grade460 ASTM Grade40 Grade60

Certificates: ISO, SGS, BV, CIQ

Length:6m 8m 9m 12m

Packaging: Export packing, packed by coil

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: How many tons per bundle?

A4: Around 2-3tons

Q5: How to avoid the rust after deliver the goods to the loading port?

- Q: What are steel rebars?

- Steel rebars are reinforced steel bars that are commonly used in construction projects to provide strength and stability to concrete structures. They are typically placed within the concrete to enhance its load-bearing capacity and help prevent cracks or failures. Rebars are made from high-strength steel and are available in various sizes and shapes to cater to different construction needs.

- Q: How are steel rebars tested for quality control?

- Steel rebars are tested for quality control through various methods such as visual inspection, dimensional measurements, and mechanical testing. Visual inspection involves checking for any surface defects or deformities. Dimensional measurements ensure that the rebars meet the specified size and length requirements. Mechanical testing involves conducting tensile, yield, and elongation tests to evaluate the strength and ductility of the rebars. These quality control tests ensure that steel rebars meet the necessary standards and are fit for use in construction projects.

- Q: What is the role of steel rebars in reducing concrete creep?

- Steel rebars play a crucial role in reducing concrete creep by providing additional tensile strength to the concrete structure. As concrete is prone to creep, which is the gradual deformation over time due to sustained loads, rebars act as reinforcement to counteract this phenomenon. By resisting the tension forces that cause creep, steel rebars help maintain the structural integrity and stability of the concrete, thus minimizing any potential deformations or cracks.

- Q: How are steel rebars protected against damage during the construction process?

- Steel rebars are typically protected against damage during the construction process by using various measures such as proper handling, storage, and covering them with protective coatings or materials like epoxy or zinc to prevent corrosion. Additionally, rebars are often positioned and supported correctly to minimize the risk of damage or bending.

- Q: How are steel rebars classified based on their shape?

- There are several types of steel rebars that are classified according to their shape. The most commonly used ones include plain round bars, deformed bars, square bars, and ribbed bars. Plain round bars are the simplest and most frequently utilized type. They have a smooth and round surface without any deformations or ribs. These bars are typically employed in cases where minimal reinforcement is needed for the concrete structure. Deformed bars, on the other hand, have ribs or deformations along their length. These ribs enhance the bond between the steel and the concrete, thereby improving structural integrity and preventing slippage. Deformed bars can be further classified based on the pattern and profile of the ribs, such as deformed high yield bars, twisted bars, and TMT (Thermo-Mechanically Treated) bars. Square bars, as their name suggests, have a square cross-section. They are mainly used in situations where additional strength and rigidity are required. Square rebars distribute loads better and are commonly utilized in building foundations, columns, and beams. Ribbed bars, also known as deformed square bars, have a square cross-section with ribs or deformations along their length. These ribs enhance the bond between the steel and the concrete, thereby providing better resistance against shear forces and improving overall structural strength. Ribbed bars are frequently used in reinforced concrete structures, such as bridges, highways, and buildings. To summarize, steel rebars are classified based on their shape into plain round bars, deformed bars, square bars, and ribbed bars. Each type of rebar offers distinct characteristics and is chosen based on the specific requirements and load-bearing capacity of the concrete structure.

- Q: What is the purpose of stirrups in steel rebar reinforcement?

- The purpose of stirrups in steel rebar reinforcement is to provide lateral support and prevent the vertical bars from buckling or collapsing under load. They help distribute the load more evenly throughout the structure, enhancing its overall strength and durability. Stirrups also help to control the spacing and positioning of the vertical bars, ensuring proper reinforcement and preventing concrete cracking or failure.

- Q: How do steel rebars affect the overall vibration resistance of a structure?

- Steel rebars can significantly enhance the overall vibration resistance of a structure. By providing additional strength and stiffness, rebars increase the structural integrity and help to distribute and dissipate vibrational energy. This reinforcement effectively reduces the magnitude of vibrations and minimizes the risk of structural damage or failure during dynamic events, such as earthquakes or high winds.

- Q: What are the safety measures to consider while handling steel rebars?

- When handling steel rebars, there are several safety measures to consider. Firstly, it is important to wear appropriate personal protective equipment such as gloves, safety goggles, and steel-toed boots to protect against potential injuries. Secondly, workers should be cautious of the weight and length of the rebars, ensuring that they do not exceed their lifting capabilities and using proper lifting techniques to prevent strains or sprains. Additionally, it is crucial to inspect the rebars for any defects or damage before use to avoid accidents during construction. Lastly, workers should be aware of their surroundings and maintain a clear and organized work area to prevent tripping or falling hazards.

- Q: What are the different types of steel rebars used in underground structures?

- There exists a variety of steel rebars that are frequently utilized in underground structures, each possessing its own unique properties and characteristics. The decision regarding which type of rebar to use depends on a multitude of factors, such as the project's specific requirements, the necessary load-bearing capacity, and the environmental conditions of the underground structure. To begin with, there are mild steel rebars, which are also referred to as carbon steel rebars. These are the most commonly employed type due to their affordability and widespread availability. Mild steel rebars possess a low carbon content and offer commendable tensile strength, rendering them suitable for general construction purposes in underground structures. Next, we have high strength deformed (HSD) rebars, which are crafted from carbon steel and undergo additional heat treatment processes. These processes result in heightened yield strength and improved resistance to corrosion. HSD rebars find common usage in areas with high seismic activity or in situations where an increased load-bearing capacity is required. Furthermore, there are epoxy-coated rebars, which are specifically designed to combat aggressive environments that underground structures can be exposed to, including moisture and chemicals. By applying an epoxy coating to the surface of the rebar, enhanced corrosion resistance is achieved. This coating acts as a protective barrier, reducing the risk of corrosion and prolonging the lifespan of the rebar. Stainless steel rebars also play a significant role in underground structures. They possess an exceptional resistance to corrosion, which makes them ideal for usage in harsh underground environments. They prove particularly beneficial in structures where chloride or other corrosive agents are present, such as underground water treatment facilities or sewer systems. Lastly, there are galvanized rebars, which are coated with a layer of zinc to provide corrosion protection. This type of rebar is commonly employed in underground structures where moisture or exposure to corrosive elements is a concern. The zinc coating acts as a sacrificial layer, corroding in place of the rebar and extending its service life. In conclusion, underground structures employ various types of steel rebars, including mild steel rebars, high strength deformed rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. The selection of the appropriate rebar type is contingent upon the specific requirements and environmental conditions of the underground structure.

- Q: How are steel rebars used in road and pavement construction?

- Steel rebars are used in road and pavement construction to provide reinforcement and enhance the structural integrity of the concrete. They are placed within the concrete mixture to withstand the tensile forces and prevent cracks or failures in the road or pavement, ensuring durability and longevity of the infrastructure.

Send your message to us

HRB335 small hot rolled deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords