Decorative Mirror Finish Anodized Aluminum Sheet - 040 Aluminum Sheets in Midnight Bronze

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

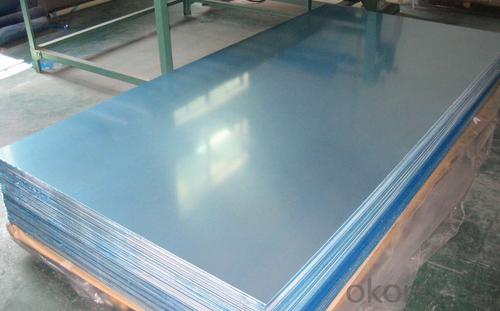

Decorative Mirror Finish Anodized Aluminum Sheet

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators ,audio equipment

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

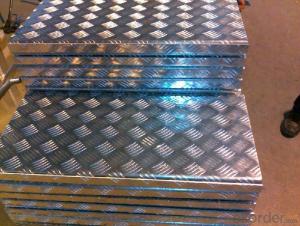

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- First, get rid of the black curtain. Black absorbs solar heat, truthfully, any dark color. Put up white or a very light color instead. That will reflect the heat back out. You can buy an insulated pull shade or use automotive window tint on the window to help too. Another idea is to cover some foam board with foil and stick that in the window. And keep your bedroom door closed since you now have a window a/c unit. Good Luck!

- Q: This question asks for an explanation of the various grades of aluminum sheets and the distinctions between them.

- <p>Aluminum sheets are categorized into different grades based on their alloy composition, which affects their properties such as strength, formability, and corrosion resistance. Common grades include 1000 series (99.00% aluminum, soft and malleable), 2000 series (aluminum-copper alloys, strong and heat treatable), 3000 series (aluminum-manganese alloys, good formability), 5000 series (aluminum-magnesium alloys, good strength and corrosion resistance), and 6000 series (aluminum-silicone-magnesium alloys, good strength and extrudability). Each grade has specific applications based on its characteristics, with 1000 series used for general purposes, 2000 series for aircraft structures, 3000 series for decorative applications, 5000 series for marine environments, and 6000 series for structural components.</p>

- Q: What are the methods used to treat the surface of aluminum sheets to improve their properties or appearance?

- <p>Surface treatment of aluminum sheets involves various processes to enhance their properties or appearance. These include anodizing, which creates a protective oxide layer; painting, which provides a decorative and protective coating; powder coating, a durable and corrosion-resistant method; polishing, which gives a shiny finish; and etching, which creates decorative patterns. Other treatments include chemical conversion coatings, such as chromate and phosphate, for corrosion resistance, and thermal spraying for wear resistance. Each method serves a specific purpose, from improving durability to aesthetic enhancement.</p>

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors in certain applications. Aluminum is known for its excellent corrosion resistance, which makes it suitable for various chemical reactions. However, it is important to consider the type of chemicals being used and their potential reactivity with aluminum. Aluminum may not be suitable for highly acidic or alkaline environments as it can react and corrode. Additionally, aluminum may not be appropriate for reactions involving certain gases or high temperatures. In such cases, alternative materials like stainless steel or glass-lined reactors may be more suitable.

- Q: This question asks for the common types of aluminum sheet windows and doors that are available in the market.

- <p>Common types of aluminum sheet windows and doors in the market include sliding windows, casement windows, fixed windows, and awning windows. For doors, there are sliding doors, swing doors, folding doors, and automatic doors. Each type has specific features and applications, such as sliding windows being space-saving and easy to operate, while casement windows offer better ventilation. Sliding doors are popular for their smooth operation and minimal space requirement, and swing doors are traditional and widely used for their durability and security. These aluminum products are valued for their strength, durability, and low maintenance requirements.</p>

- Q: Are aluminum sheets suitable for chemical storage tanks?

- Yes, aluminum sheets can be suitable for chemical storage tanks depending on the specific requirements of the chemical being stored. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing many chemicals. It forms a protective oxide layer that prevents further corrosion, even when exposed to harsh environments. However, it is important to consider the compatibility of the chemical with aluminum. Some chemicals, such as strong acids or bases, may react with aluminum and cause corrosion or other undesirable reactions. In such cases, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) may be more suitable. Additionally, the thickness and grade of the aluminum sheets should be chosen carefully based on the specific chemical being stored and the tank's intended use. Thicker sheets may be necessary for storing highly corrosive or hazardous chemicals, while thinner sheets may be sufficient for less aggressive substances. Overall, aluminum sheets can be a suitable choice for chemical storage tanks, but it is crucial to carefully evaluate the chemical compatibility and select the appropriate thickness and grade of aluminum to ensure safe and reliable storage.

Send your message to us

Decorative Mirror Finish Anodized Aluminum Sheet - 040 Aluminum Sheets in Midnight Bronze

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords