5086 Aluminum Coil - DC and CC 1/3/5/6/8 Series Mill Finish Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DC and CC 1/3/5/6/8series Mill Finish Aluminium coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

1.Aluminium coil application: building, celling, roofing, refrigerator, etc.

2.DC (hot rolling) and CC (continue cast) production lines, good perpority, no wave, no scratch

3.General alloy temper and specification see below table:

Product | Alloy | Temper | Size (mm) | Remark | ||

Thickness | Width | I.D. (mm) | ||||

Aluminum Coil | 1070 1060 1050 1145 1235 1035 1100 1200 3A21 3003 3004 3105 3103 8011 5052 5005 5754 6061 6063

| H18 H16 H26 H14 H24 O | 0.2-7.0 | 660-2200 | 150-600 | Edge without sheared |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

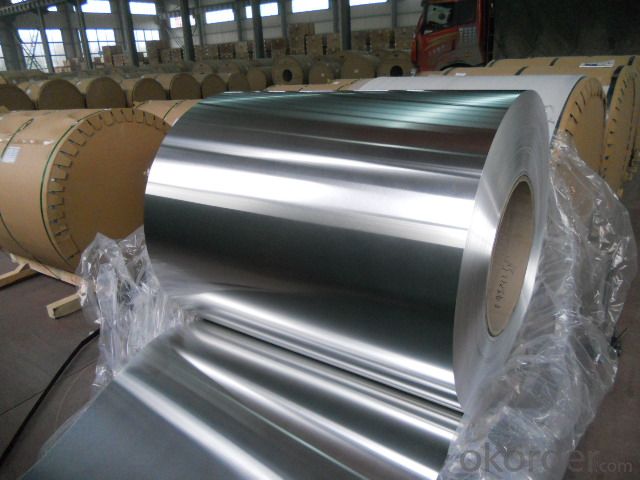

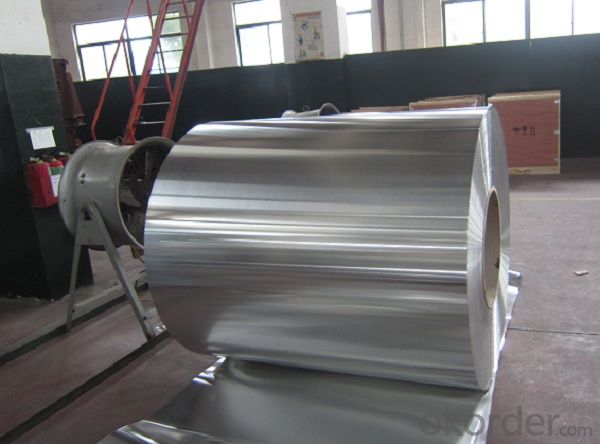

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: hello, i have been recently studying the production of aluminum from aluminum dross (recycling of aluminum) .this chemical equations represents the hydrolization of sodium aluminate to obtain aluminum hydroxide :Na2Al2O4 + 4H2O -----------gt; 2Al(OH)3 + 2NaOHafter that the next step is to produce Al2O3the next step to obtain Aluminum is to pass a current through the solution (electrolysis)this is the part that i don't get .... how could we electrolyze Aluminium oxide to produce aluminum if we are recycling aluminum ... i mean electrolysis consumes most of the energy and is very expensive .... so how do electrolysis be used in the recycling industry...please answer ... all answers are really appreciated ....and correct me if my informations are wrong...

- As Aluminum dross composition will vary from different sources Electrolytic aluminium dross w(Al)25.58, w(Al2O3)31.55, w(SiO2)5.56, w(Na2O)2~3, w(MgO)2.0~3.0, w(CaO)2.00, w(FeO)+ w(MnO)1.0 Cast aluminum dross w(Al)10, w(Al2O3)50~60, w(SiO2)3.0~5.0, w(Na2O)1.0~1.5 w(MgO)2.0~3.0, w(CaO)1. 5~3.0, w(FeO)+ w (MnO)1.0 The most popular way is mechanical recover aluminum from aluminum dross. Rotary furnace and aluminum dross recovery machine can do this work easily and effectively. You can put heating flux in the processing to get the certain temperature for the dross, them aluminum dross can be processed in the rotary furnace or aluminum dross processing machine, aluminum will be recycled from aluminum dross. It is automatic and that is such simple!

- Q: What are the differences between aluminum coil 3003h24 and 3a21h14?

- The mechanical property references of rolled plate 3003 H24and 3A21 H14 are as follows: 3003 H24--Rm/MPa≧140-180;Rp0.2/MPa≧115;A(%)≧1-5(thickness 0.2mm-4.5mm)3A12 H14--Rm/MPa≧145-215;A(%)≧6

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- If you are using a frying pan on a gas stove - yes. I fold tin foil into a strongish ribbon then form the shape I want: hearts, gingerbread men, etc. Make sure the pan is fairly warm before you put the tin foil shape in remove the shape as soon as the pancake is set, but before you flip it. You can trim the little splashes before serving. HOWEVER - there are reusable shapes available at many kitchen supply stores. They are not very expensive are permanent additions to your kitchen.

- Q: How are aluminum coils protected against galvanic corrosion?

- Aluminum coils are protected against galvanic corrosion through various methods, such as applying a protective coating or using sacrificial anodes. These measures help to create a barrier between the aluminum and other metals, preventing the occurrence of galvanic corrosion.

- Q: Can aluminum coils be used in food processing industries?

- Aluminum coils find applications in the food processing industry. This is because aluminum possesses several advantageous properties that make it a popular choice in this field. It is a lightweight and flexible material with excellent thermal conductivity. These characteristics make it ideal for various uses such as refrigeration, heat exchangers, and ovens in food processing. Moreover, aluminum is non-toxic, resistant to corrosion, and does not affect the taste or odor of the food being processed. Therefore, it is a safe and hygienic option for food processing equipment. Additionally, aluminum coils are easy to clean and maintain, ensuring the highest standards of cleanliness and food safety are upheld. Consequently, due to their outstanding performance and suitability for food-related applications, aluminum coils are widely accepted and utilized in the food processing industry.

- Q: Can aluminum coils be customized according to specific requirements?

- Indeed, aluminum coils possess the capability to be personalized in accordance with particular demands. To accommodate diverse applications, aluminum coils can undergo customization to suit distinct dimensions, thicknesses, and finishes. The range of customization options encompasses specific alloys, tempering processes, and even specialized coatings, which serve to enhance corrosion resistance or augment appearance. Furthermore, aluminum coils can be fabricated with specific attributes such as perforations, embossing, or edge treatments, tailored to fulfill precise functional or aesthetic prerequisites. The inherent ability of aluminum coils to be customized bestows upon them a quality of flexibility and versatility, rendering them invaluable across a multitude of industries and applications.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum coils are lightweight, which makes them an excellent choice for automotive manufacturers as it helps to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and performance. Additionally, aluminum coils have excellent heat conductivity, which is crucial in automotive applications where heat dissipation is important. Moreover, aluminum coils have good corrosion resistance, which is particularly beneficial in automotive applications where vehicles are exposed to various weather conditions and road salts. Overall, the use of aluminum coils in automotive applications can provide several advantages such as weight reduction, improved fuel efficiency, better heat dissipation, and enhanced corrosion resistance.

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- over time excessive use leeches into the system and aluminium is a toxic metal that the blood- brain can not be protect against, and causes all sorts of permanent neurological damage, alzheimers, senility, parkinsons, MS, lots of things are linked to heavy metal toxicity, proven of course. Why don't you save your brain AND save money and buy yourself a tray that fits in the toaster oven so it can be reused. Obviously your brain health should be more important than money, but if you need more reason to stop using aluminum, think about the money you are throwing away several times a week that can be saved. Of course you'd save even more money if you stopped buying expensive pre-packaged frozen foods :D but I think the health of the brain has way more value than what's in your wallet in the long run.

- Q: Is it possible to utilize a grinder to smooth out or remove a damaged area on a steel coil?

- <p>Yes, you can use a grinder to grind down a damaged section of a steel coil. However, it's crucial to use the appropriate type of grinder designed for metalworking and to ensure safety precautions are taken, such as wearing protective gear. The grinder should be capable of handling the hardness of the steel and should be operated by someone experienced with such equipment. Always follow the manufacturer's guidelines and safety standards to prevent accidents and ensure the effectiveness of the grinding process.</p>

- Q: How are aluminum coils stored and transported?

- Aluminum coils are typically stored and transported in various ways depending on their size and weight. They are commonly stored in warehouses or outdoor storage facilities, where they are organized and stacked horizontally on pallets or racks. To ensure their protection, coils are often covered with a protective material such as plastic or shrink wrap. When it comes to transportation, aluminum coils are usually loaded onto trucks, containers, or flatbed trailers for long-distance journeys. To prevent damage during transit, the coils are secured using straps, chains, or other fastening methods. Additionally, specialized equipment like coil racks or cradles can be used to provide extra support and stability. Overall, proper storage and transportation practices are crucial to maintain the integrity of aluminum coils and prevent any potential harm.

Send your message to us

5086 Aluminum Coil - DC and CC 1/3/5/6/8 Series Mill Finish Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords