Skidded Mill Finish Aluminum Coil DC and CC 1/3/5/6/8 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium coil DC and CC 1/3/5/6/8 Series

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Mill Finish Aluminium coil DC and CC 1/3/5/6/8 Series

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium coil DC and CC 1/3/5/6/8 Series

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

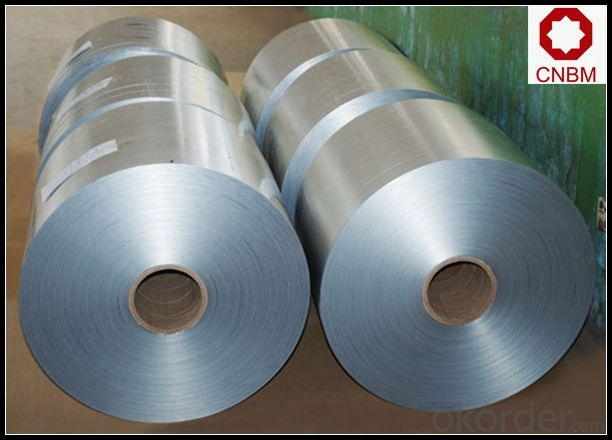

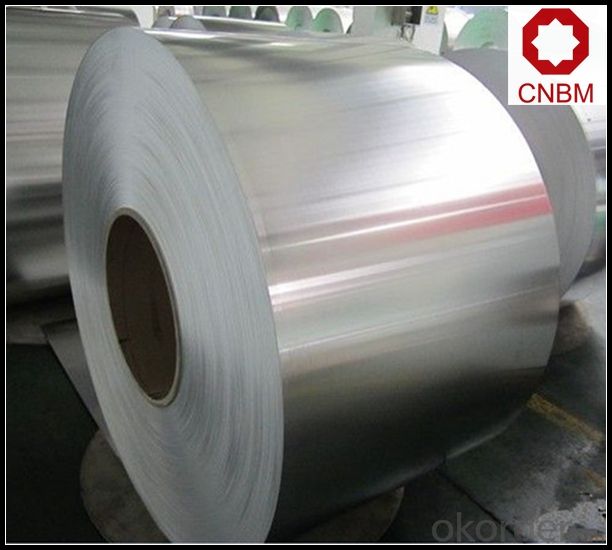

5. Image of Mill Finish Aluminium coil DC and CC 1/3/5/6/8 Series

6. Package and shipping of Mill Finish Aluminium coil DC and CC 1/3/5/6/8 Series

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to noise isolation?

- There are multiple ways in which noise isolation can be enhanced with the help of aluminum coils. To begin with, the utilization of aluminum as a material for coils offers exceptional thermal and electrical conductivity, facilitating the dispersion of heat and electromagnetic interference. This, in turn, diminishes the likelihood of noise generated by these factors. Furthermore, noise isolation can be improved by designing aluminum coils with specific properties. By employing thicker aluminum wire, the coil's resistance can be increased, thereby reducing the transmission of electrical noise. Moreover, optimizing the shape and size of the coil can minimize vibrations and resonance, common sources of noise. In addition, the integration of aluminum coils with other noise isolating materials can yield beneficial results. For instance, combining them with acoustic foam or other sound-absorbing materials can create a barrier that prevents sound transmission. The aluminum coil serves as a structural support, while the additional materials absorb and dampen sound waves, further enhancing noise isolation. In conclusion, aluminum coils contribute to noise isolation by dispersing heat and electromagnetic interference, minimizing vibrations and resonance, and providing structural support for other noise isolating materials.

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- Well, there are aluminum alloys that have copper in them (although they usually have other metals also), so I don't think it would be a problem. If you're thinking of copper plated aluminum, there is the potential for a galvanic reaction (meaning like a battery cell) that could cause the coin to corrode and fall apart. It's the same problem with the current production of US cents (which are copper coated zinc).

- Q: How are aluminum coils used in the production of electronic devices?

- Aluminum coils are used in the production of electronic devices for various purposes such as providing electrical conductivity, heat dissipation, and electromagnetic shielding. These coils are typically used in components like transformers, inductors, and motors, where they help in the efficient transfer of electrical energy. Additionally, aluminum coils are often employed in cooling systems to dissipate heat generated by electronic components, ensuring their optimal performance and preventing overheating. Furthermore, aluminum coils can be utilized to create electromagnetic shields that protect sensitive electronic circuits from external electromagnetic interference, thus enhancing the overall reliability and functionality of electronic devices.

- Q: Are aluminum coils resistant to impact damage?

- Yes, aluminum coils are generally resistant to impact damage. Aluminum is known for its high strength-to-weight ratio and excellent durability, which makes it less susceptible to impact damage compared to other materials. Additionally, aluminum coils are often used in various industries where they are exposed to various environmental conditions and handling processes, and they are designed to withstand such impacts without getting damaged easily. However, it is important to note that the level of resistance to impact damage can vary depending on the specific thickness, quality, and design of the aluminum coil.

- Q: Are there any limitations on the embossing of aluminum coils?

- There exist several limitations when it comes to embossing aluminum coils. One limitation pertains to the thickness of the aluminum coil. Thicker coils, in general, pose more difficulty during the embossing process due to the increased force required to achieve the desired pattern. Furthermore, if the thickness is already close to the upper limit for embossing, the embossing process may cause the coil to stretch or distort. Another limitation concerns the complexity of the embossing design. Elaborate or intricate patterns can prove to be more challenging to achieve on aluminum coils, particularly if they possess a lower gauge or thickness. In such cases, the embossing process may not be capable of accurately reproducing intricate designs, resulting in a less defined or distorted pattern. The size of the aluminum coil is also a potential limitation. If the coil is excessively large, achieving even embossing across the entire surface may prove difficult. This could lead to inconsistencies in the embossed pattern or the application of uneven pressure to the coil during the embossing process. Lastly, the type and quality of the aluminum can restrict the embossing capabilities. Different alloys or grades of aluminum possess varying levels of malleability and resistance to embossing. Certain alloys may be prone to cracking or deforming during the embossing process, thereby limiting the range of patterns that can be achieved. Overall, the embossing of aluminum coils is subject to limitations such as thickness, design complexity, size, and aluminum quality. It is crucial to consider these factors when embossing aluminum coils in order to attain the desired outcomes.

- Q: Are aluminum coils suitable for interior decorative applications?

- Indeed, interior decorative applications are well-suited for aluminum coils. This material, being lightweight and flexible, lends itself to effortless shaping into diverse forms, thus making it perfect for decorative purposes. Moreover, aluminum offers a vast array of finishes, colors, and patterns, granting limitless design options. In addition, its remarkable durability and corrosion resistance guarantee its enduring aesthetic appeal. Furthermore, aluminum is an environmentally friendly choice, as it can be recycled indefinitely, making it a sustainable material for interior decorations. All in all, aluminum coils offer a cost-effective and visually appealing alternative for interior decorative applications.

- Q: What are the methods to prevent rust formation on steel coils during storage and transportation?

- <p>To prevent rust on steel coils during storage and transportation, follow these steps: 1. Keep the coils dry and avoid exposure to moisture. 2. Use rust inhibitors or anti-corrosion coatings on the coils. 3. Store the coils in a clean, dry, and well-ventilated area. 4. Use protective wrapping materials like plastic film or corrosion-resistant paper. 5. Ensure proper stacking and avoid direct contact between coils. 6. Use rust-resistant materials for transportation containers. 7. Regularly inspect the coils for signs of rust and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rust formation on steel coils.</p>

- Q: I think the use of aluminum, at the lower levels, has really hurt US born players. To give a kid a piece of metal, and expect him to use wood when drafted........ I think US should go back to wood, whatever the costs (I know the aluminum is far cheaper). Thoughts....Cheers.

- i kinda agree, im a little in the middle. when your younger you want a kid to have fun and a great time white playing, because a kid cant hit a ball as far with a piece of wood than he would with an aluminum bat.. know what im saying?

- Q: What is the maximum operating temperature for aluminum coils?

- The maximum operating temperature for aluminum coils typically ranges from 200 to 250 degrees Celsius.

- Q: How are aluminum coils used in the production of heat sinks?

- Aluminum coils play a vital role in the production of heat sinks due to their excellent thermal conductivity and malleability. Heat sinks are designed to dissipate the excess heat generated by electronic components such as processors, integrated circuits, and power transistors. By utilizing aluminum coils in the manufacturing process of heat sinks, several key advantages are realized. Firstly, aluminum coils possess high thermal conductivity, which allows for efficient transfer of heat from the electronic component to the heat sink. This is crucial for maintaining the optimal operating temperature of the electronic device, as excess heat can cause performance degradation and even permanent damage. The high thermal conductivity of aluminum ensures that the heat is rapidly dissipated away from the electronic component, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various designs required for heat sinks. Heat sinks are available in different sizes and shapes, with the most common being finned heat sinks. The fins on the heat sink increase the surface area, allowing for greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling the heat sink to effectively release heat into the surrounding environment. Additionally, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that the heat sink does not add significant weight to the electronic device, which is especially important in applications where weight restrictions are crucial, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum ensure the longevity and durability of the heat sink, even in harsh environments. In conclusion, aluminum coils are essential components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion-resistant properties. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately prolonging the lifespan of electronic devices.

Send your message to us

Skidded Mill Finish Aluminum Coil DC and CC 1/3/5/6/8 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords