Aluminum Coil Philippines - DC and CC Mill Finish Aluminum Coil 1/3/5/6/8 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of DC and CC Mill Finish Aluminium Coil 1/3/5/6/8 Series

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of DC and CC Mill Finish Aluminium Coil 1/3/5/6/8 Series

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of DC and CC Mill Finish Aluminium Coil 1/3/5/6/8 Series

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

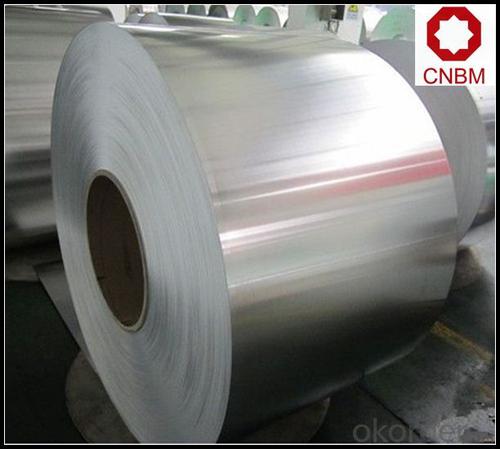

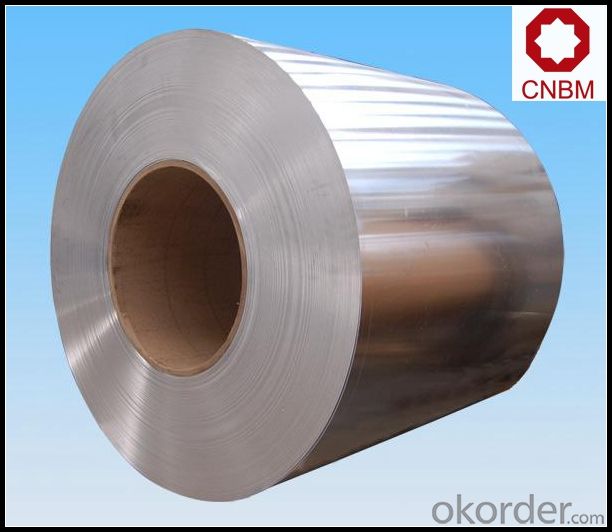

5. Image of DC and CC Mill Finish Aluminium Coil 1/3/5/6/8 Series

6. Package and shipping of DC and CC Mill Finish Aluminium Coil 1/3/5/6/8 Series

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils possess unique properties and advantages, allowing them to be employed in a wide range of potential applications. Here are some of the primary areas where they can be utilized: 1. Architectural: The distinct properties of coil-anodized aluminum make it well-suited for architectural purposes, including cladding, roofing, and facades. With its anodized coating, it offers increased durability, resistance to weather conditions, and color stability, making it suitable for outdoor use in various climates. Furthermore, the coils can be shaped and formed to create different architectural elements, providing design flexibility. 2. Transportation: Due to its lightweight nature, coil-anodized aluminum is ideal for transportation applications. It can be employed in the manufacturing of parts and components for the automotive, aerospace, and marine industries. The anodized coating enhances its corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils find utility in the field of electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications necessitating high conductivity and insulation. It can be utilized in the production of components such as heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors achieved through coil-anodizing make it a perfect material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, rendering it suitable for both indoor and outdoor applications. It enables the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be employed in the manufacture of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can be utilized in diverse industrial sectors. The anodized coating offers enhanced corrosion resistance, which is advantageous in industries such as chemical processing, food processing, and pharmaceuticals. It can be used in the production of tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be employed in the manufacturing of solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. In conclusion, coil-anodized aluminum coils have extensive and diverse potential applications, spanning across architectural, transportation, electronics, signage, furniture, industrial, and energy sectors. The combination of its lightweight nature, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: Are there any limitations to the maximum coil diameter of aluminum coils?

- There exist limitations on the maximum coil diameter of aluminum coils. Factors such as the type and thickness of the aluminum, the coiling equipment, and the intended application of the coil determine the maximum coil diameter. Thinner and more ductile aluminum alloys generally allow for larger coil diameters. However, maintaining the structural integrity of the coil and preventing deformation, wrinkling, or damage during handling and transportation becomes increasingly challenging as the coil diameter increases. Moreover, the coiling equipment may have its own restrictions on the maximum diameter it can handle. Hence, it is crucial to take these factors into consideration when determining the maximum coil diameter for aluminum coils.

- Q: What is virgin aluminum? I can't find anything about it, is it just another word for aluminum? Is there a difference?

- virgin aluminum is, aluminum that has not been printed on, mixed with other metals etc. It is simply a more pure form of aluminum and will net more upon resale to a junkman

- Q: What are the different sizes available for aluminum coils?

- Aluminum coils come in various sizes to accommodate the diverse needs of different industries and applications. The sizes of aluminum coils can vary depending on factors such as intended use, manufacturing process, and customer preferences. In general, aluminum coils can be found in a range of thicknesses, typically spanning from 0.2mm to 8mm. The width of aluminum coils can range from a few inches to over 60 inches. As for length, aluminum coils can be customized, but standard lengths usually fall between 1000mm and 6000mm. The specific sizes of aluminum coils available may also be influenced by the manufacturing capabilities of the supplier or manufacturer. Some suppliers may offer a wide selection of sizes to cater to different customer demands, while others may have a more limited range. It is important to note that the availability of specific sizes may be subject to minimum order quantities or lead times. Therefore, it is advisable to consult with the supplier or manufacturer to inquire about the available sizes and any associated limitations or requirements. Overall, the assortment of sizes for aluminum coils allows customers the flexibility to select dimensions that best suit their specific applications and requirements.

- Q: Can aluminum coils be used in electrical busbars?

- Yes, aluminum coils can be used in electrical busbars. Aluminum offers good conductivity, is lightweight, and cost-effective, making it suitable for use in busbars. However, proper insulation and connection techniques must be employed to address the higher thermal expansion and potential corrosion issues associated with aluminum.

- Q: How do aluminum coils perform in saltwater environments?

- Aluminum coils perform exceptionally well in saltwater environments due to their natural resistance to corrosion. Unlike other metals, aluminum forms a protective oxide layer when exposed to saltwater, creating a barrier that prevents further corrosion. This oxide layer acts as a durable and long-lasting shield against the harsh effects of saltwater, ensuring the longevity and performance of aluminum coils in marine applications. Additionally, aluminum coils are lightweight and possess high thermal conductivity, making them popular choices for heat exchangers and condensers in saltwater-based cooling systems. Overall, aluminum coils are highly reliable and efficient in saltwater environments, making them a preferred choice for various marine applications.

- Q: Consider the following ionization energies for aluminum:Al(g) → Al+(g) + eI1 = 580 kJ/molAl+(g) → Al2+(g) + eI2 = 1815 kJ/molAl2+(g) → Al3+(g) + eI3 = 2740 kJ/molAl3+(g) → Al4+(g) + eI4 = 11,600 kJ/mol A) Account for the trend in the values of the ionization energies.B) Explain the large increase between I3 and I4.

- aluminum forms an ion by loosing electrons. once an electron is lost, the nucleus attains net positive charge. as a result, the remaining electrons are strongly held by nuclea force of attraction, hence more energy is required to remove them.

- Q: What are the maintenance requirements for aluminum coils?

- The maintenance requirements for aluminum coils typically involve regular cleaning to remove dirt and debris, inspection for any signs of corrosion or damage, and ensuring proper airflow around the coils to prevent overheating. Additionally, periodic lubrication of moving parts and regular filter replacement are recommended to maintain optimal performance and efficiency.

- Q: Is it possible to use aluminum coil as a material for crafting jewelry?

- <p>Yes, you can use aluminum coil to make jewelry. Aluminum is lightweight, affordable, and easy to work with, making it a popular choice for crafting. It's also hypoallergenic, which is a plus for those with metal sensitivities. However, it's softer than metals like sterling silver or gold, so it may require more care to prevent denting or bending. Aluminum can be shaped, cut, and polished to create various jewelry designs, but it may not hold up as well over time or under heavy use compared to harder metals.</p>

- Q: What are the typical delivery methods for aluminum coils?

- Aluminum coils are transported using various delivery methods, which depend on the size and quantity of the coils. However, there are several commonly used methods in the industry. Trucks are one of the most frequently employed methods. Aluminum coils are typically transported on flatbed trucks, providing a secure and stable platform during transit. This method is suitable for both short and long-distance deliveries, and it allows for easy loading and unloading at the destination. Rail transportation is another popular method. It is often used when larger quantities of aluminum coils need to be delivered or when the distance is significant. Rail cars equipped with flatbeds or specialized coil cars are used to transport the coils safely and efficiently. This method is particularly advantageous for long-distance deliveries, as it is generally more cost-effective and eco-friendly compared to other modes of transportation. Sea transportation is sometimes used for delivering aluminum coils. This method is commonly employed for international shipments or when the coils need to be transported over long distances. Coils are typically packed into containers to ensure their safety and protection during the journey. Although shipping by sea allows for efficient transportation of large quantities of coils, it may take longer due to customs procedures and port handling. For smaller quantities of aluminum coils, air freight can be utilized. This method is often chosen when time is of the essence or for urgent shipments. Airplanes with cargo holds are used to transport the coils, ensuring their safe and expedited delivery. However, it is generally more expensive than other delivery methods, so it is typically reserved for time-sensitive or high-value shipments. In conclusion, the delivery methods for aluminum coils include trucks, rail, sea, and air. The appropriate method is selected based on factors such as size, quantity, distance, urgency, and cost considerations.

Send your message to us

Aluminum Coil Philippines - DC and CC Mill Finish Aluminum Coil 1/3/5/6/8 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords