Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profile for Marine Ship Deck Making Description

Aluminium Profile for Marine Ship Deck Making is one semi-finished aluminium material. The alloy AA5083 T6 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profile for Marine Ship Deck Making

Aluminum Extrusion | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profile for Marine Ship Deck Making

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profile for Marine Ship Deck Making

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profile for Marine Ship Deck Making

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

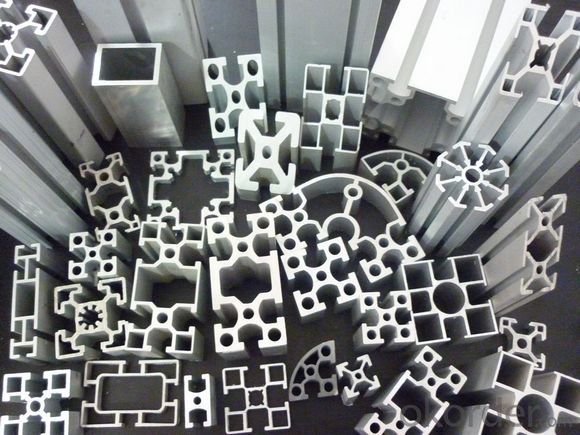

6. Image of Aluminium Profile for Marine Ship Deck Making

7. Package and shipping of Aluminium Profile for Marine Ship Deck Making

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum profiles contribute to energy-efficient lighting systems?

- Enhancing the energy efficiency of lighting systems is a significant role played by aluminum profiles. The lightweight and highly conductive nature of aluminum allows for efficient heat dissipation, which is crucial in maintaining the lifespan and efficiency of bulbs. By utilizing aluminum profiles, the generated heat from the light source can be effectively transferred away, ensuring optimal performance and longevity. Additionally, aluminum profiles offer versatility and the ability to accommodate various lighting components such as LED strips or bulbs, reflectors, and lenses. These profiles provide a stable and secure housing for these components, preventing any damage or misalignment that could affect the efficiency of the lighting system. Furthermore, precision engineering in aluminum profiles makes installation and maintenance easy, further contributing to the overall energy efficiency of the system. Another significant advantage of aluminum profiles is their capability to act as a heat sink. By diverting heat away from the light source, the profiles help maintain lower operating temperatures, resulting in reduced energy consumption and increased efficiency of the lighting system. This is especially important for LED lighting, as they are sensitive to heat and can experience a decline in light output if not adequately cooled. Aluminum profiles enable efficient thermal management, ensuring that LED lights operate at their optimum level, saving energy and reducing the need for frequent replacements. Moreover, aluminum is a recyclable material, making it an environmentally friendly choice for lighting systems. The usage of aluminum profiles promotes sustainable practices by reducing the demand for raw materials and minimizing waste. This aligns with the principles of energy efficiency and conservation, as it reduces the overall carbon footprint of the lighting system. In summary, aluminum profiles contribute to energy-efficient lighting systems by facilitating effective heat dissipation, providing a stable housing for lighting components, acting as a heat sink, and promoting sustainable practices. These profiles enhance the performance, lifespan, and energy efficiency of lighting systems, making them an essential component in modern lighting solutions.

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles possess exceptional durability and resilience, making them highly adept at tackling extreme weather conditions. Their inherent resistance to corrosion allows them to endure harsh weather elements like heavy rain, snow, temperature fluctuations, and intense UV radiation without succumbing to deterioration or corrosion. A key characteristic of aluminum is its ability to form a protective oxide layer, known as aluminum oxide, on its surface. This layer acts as a natural barrier, shielding the metal from moisture, salt, and other corrosive agents found in the atmosphere. Consequently, aluminum profiles remain unaffected by rain or snow, and they do not rust or corrode like other metals. Additionally, aluminum's thermal conductivity enables it to rapidly dissipate heat, preventing any harm caused by extreme temperature changes. Regardless of exposure to scorching heat or freezing cold, aluminum profiles undergo minimal expansion and contraction, which helps maintain their structural integrity and prevents warping or cracking. Furthermore, aluminum profiles can withstand high wind loads, making them suitable for areas prone to hurricanes, tornadoes, or strong gusts. Their lightweight yet sturdy composition allows them to endure significant pressure without bending or breaking. Regarding UV radiation, aluminum profiles exhibit excellent resistance to fading and discoloration. They can effectively withstand prolonged exposure to sunlight without losing their original color or surface finish. This renders them an ideal choice for outdoor applications, such as windows, doors, and facades, where they retain their visual appeal and structural soundness even in extreme weather conditions. In summary, aluminum profiles display remarkable durability, corrosion resistance, thermal stability, and resistance to UV radiation, enabling them to effectively handle and withstand the challenges presented by extreme weather conditions.

- Q: What are the surface finishes available for aluminum profiles?

- There are several surface finishes available for aluminum profiles, each offering different aesthetics and properties. Some of the common surface finishes for aluminum profiles include: 1. Mill Finish: This is the standard finish obtained directly from the mill without any additional treatment. It has a raw appearance with visible manufacturing marks and is typically used for structural applications where aesthetics are not a concern. 2. Anodized Finish: This finish involves an electrochemical process that creates a protective oxide layer on the surface of the aluminum, resulting in increased corrosion resistance and durability. Anodized finishes are available in various colors and can provide a glossy or matte appearance, making them popular for decorative applications. 3. Powder Coating: Powder coating involves applying a dry powder onto the aluminum surface and then curing it in an oven. This finish provides excellent durability, corrosion resistance, and a wide range of color options. It can also offer various textures, such as smooth, matte, or textured, allowing for customization according to specific design requirements. 4. Brushed Finish: This finish is achieved by brushing the aluminum surface with abrasive materials to create a pattern of fine lines, giving it a brushed appearance. This finish is commonly used to add a decorative touch to aluminum profiles and can offer a sleek and modern look. 5. Polished Finish: Polishing involves using abrasive materials to create a smooth and shiny surface on the aluminum. This finish can range from a high gloss mirror-like appearance to a satin finish. Polished finishes are often used in architectural applications where a reflective and visually appealing surface is desired. 6. Wood Grain Finish: This finish involves applying a special coating to the aluminum surface, mimicking the appearance of wood grain. It provides a natural and warm look, making it suitable for applications where a wood-like aesthetic is desired without the maintenance requirements of actual wood. These are just a few examples of the surface finishes available for aluminum profiles. The choice of finish depends on the intended application, desired appearance, and specific requirements such as corrosion resistance, durability, and ease of maintenance.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: What are the advantages of utilizing recycled aluminum in construction projects in terms of environmental impact?

- <p>Using recycled aluminum profiles in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining bauxite, which is the primary source of aluminum. This reduction in mining decreases habitat destruction and soil erosion. Additionally, recycling aluminum requires significantly less energy compared to producing it from raw materials, which cuts down on greenhouse gas emissions and reduces the overall carbon footprint. Furthermore, the use of recycled aluminum helps in waste management by diverting materials from landfills, thereby reducing pollution and the environmental burden of waste disposal.</p>

- Q: Which aluminum profile is better here in Guangdong?

- I think it should be a male aluminum bar, doing things very reassuring, things are also very good. Satisfied, please adopt ha!

- Q: This question asks for an enumeration of the various types of aluminum profiles that are commonly utilized in interior wall systems.

- <p>Aluminum profiles for interior wall systems come in various types, each serving a specific purpose. These include: 1. Cover Profiles, which conceal the joints between wall panels; 2. Angle Profiles, used for creating corners and edges; 3. Connecting Profiles, facilitating the attachment of panels; 4. Support Profiles, providing structural support; 5. Joint Profiles, for aligning and securing panels at their joints; 6. Decorative Profiles, adding aesthetic appeal; 7. Insulation Profiles, for thermal insulation; and 8. Sealing Profiles, to prevent air and moisture infiltration. Each type of profile is designed to meet specific architectural and functional requirements, contributing to the overall integrity and appearance of the interior wall system.</p>

- Q: How do you join two aluminum profiles together?

- One common method to join two aluminum profiles together is by using aluminum extrusion connectors. These connectors are designed to fit into the profile's T-slot or slot, allowing them to be easily connected and secured using screws or bolts. This method provides a strong and durable connection, ideal for constructing various structures and frames.

- Q: How do aluminum profiles perform in terms of corrosion resistance?

- Aluminum profiles are known for their excellent corrosion resistance. Due to the formation of a protective oxide layer on the surface, aluminum profiles are highly resistant to corrosion, even in harsh environments. This oxide layer acts as a barrier, preventing further oxidation and corrosion. Additionally, aluminum profiles can be further enhanced through various surface treatments such as anodizing or powder coating, which provide additional protection against corrosion. Overall, aluminum profiles offer exceptional corrosion resistance, making them suitable for a wide range of applications, including construction, transportation, and manufacturing industries.

- Q: Why should aluminum surface treatment process?

- He devotes himself to aluminum passivation, electroplating and surface treatment, and has problems to visit at any time.

Send your message to us

Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords