Customized High Quality Good Price 5083 Aluminum Prepainted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepaited Coil Hight Quality Good Price Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepaited Coil Hight Quality Good Price:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

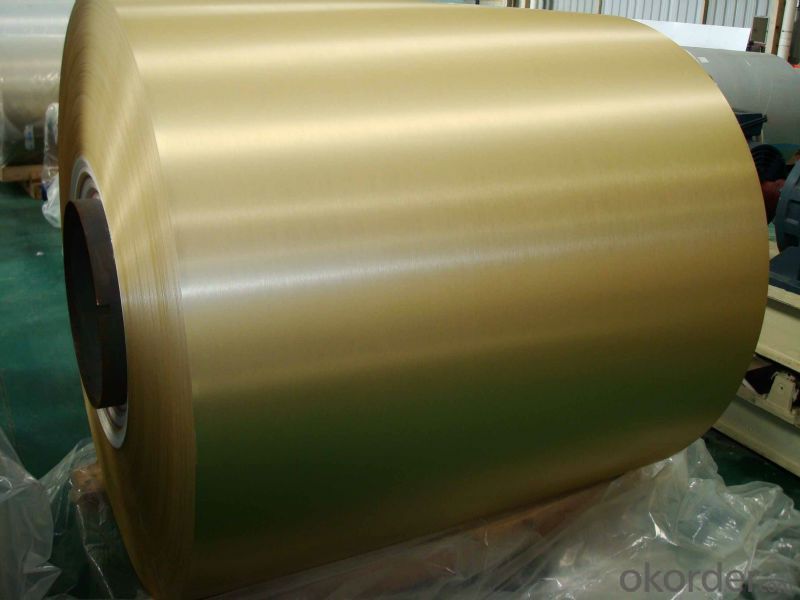

Images of the Aluminium Prepaited Coil Hight Quality Good Price:

Aluminium Prepaited Coil Hight Quality Good PriceSpecification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How are aluminum coils joined together to form larger panels?

- Aluminum coils are joined together to form larger panels through a process called coil coating or coil joining. In this process, the edges of the coils are aligned and then welded, soldered, or bonded together using specialized techniques and adhesives. This ensures a strong and seamless connection between the coils, resulting in a larger aluminum panel.

- Q: Can aluminum coils be used in roofing applications?

- Aluminum coils are indeed suitable for roofing purposes. The lightweight, corrosion-resistant, and durable properties of aluminum make it a popular option for roofing. In the construction of various roofing systems like standing seam roofs, metal shingles, and flat roofs, aluminum coils are commonly utilized. These coils are typically shaped into panels or sheets, which are then installed on the roof, offering protection against weather conditions and enhancing the overall appearance of the building. Moreover, the reflective attributes of aluminum play a role in reducing energy consumption. By deflecting sunlight and heat, this environmentally friendly roofing choice helps in conserving energy.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a lightweight, versatile, and corrosion-resistant material that can be easily slit into narrow strips without compromising its structural integrity. Aluminum coils are commonly used in various industries such as automotive, construction, and packaging, where precise and narrow strips are required for specific applications. Additionally, aluminum coils offer excellent formability and surface quality, making them suitable for coil slitting processes that require high precision and consistency.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Cryogenic storage tanks can incorporate aluminum coils, as aluminum is a suitable material for such purposes. This is due to its low density, high thermal conductivity, and excellent resistance to corrosion. These attributes make it an excellent choice for the storage and transportation of cryogenic liquids like liquid nitrogen, oxygen, and argon. Aluminum coils can be utilized to construct the internal shell of the tank, which offers a lightweight and durable solution. Moreover, aluminum is highly malleable, enabling the creation of intricate tank shapes and designs. However, it is crucial to consider that aluminum has a higher coefficient of thermal expansion compared to materials such as stainless steel. Therefore, adequate design measures must be implemented to accommodate thermal contraction and expansion during cryogenic operations.

- Q: Can aluminum coils be used in the production of aluminum ceilings?

- Yes, aluminum coils can be used in the production of aluminum ceilings. Aluminum coils are commonly used in the manufacturing of various aluminum products, including aluminum ceilings. These coils are typically made from high-quality aluminum alloy, which is then processed and formed into coils of the desired thickness and width. The coils can be easily cut and shaped into the desired dimensions for the ceiling panels. Additionally, aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for ceilings. It is also highly versatile, allowing for a variety of finishes and designs to be applied to the aluminum surface, further enhancing the aesthetic appeal of aluminum ceilings. Overall, aluminum coils are a key component in the production of aluminum ceilings, providing a reliable and long-lasting material for these types of applications.

- Q: Can aluminum coils be utilized as an insulating material?

- <p>Aluminum coils are not typically used for insulation. They are good conductors of heat and electricity, which makes them unsuitable for insulation purposes. Insulation materials should be poor conductors to prevent the flow of heat or electricity. Aluminum coils are more commonly used in applications where conductivity is desired, such as in electrical wiring or heat exchangers. For insulation, materials like fiberglass, mineral wool, or plastic foams are used because they resist heat flow effectively.</p>

- Q: What are the potential applications of coil-stucco aluminum coils?

- Coil-stucco aluminum coils possess distinctive properties and characteristics, resulting in a broad range of potential applications. Some of these applications include: 1. Building and construction: Within the construction industry, coil-stucco aluminum coils find widespread use for various purposes. They offer durability, versatility, and aesthetic appeal when employed in roofing, cladding, and siding applications. The stucco finish on the coils adds texture and enhances the overall appearance of buildings. 2. Transportation industry: The transportation industry also utilizes coil-stucco aluminum coils for the manufacturing of trailers, truck bodies, and other vehicles. Aluminum, being lightweight yet strong, proves to be an ideal material for reducing vehicle weight and increasing fuel efficiency. The stucco finish on the coils adds strength and resistance against scratches and abrasions. 3. Appliances and electronics: Coil-stucco aluminum coils are suitable for the manufacturing of appliances and electronics due to their corrosion resistance and thermal conductivity. Commonly found in refrigerators, air conditioning units, and other household appliances, aluminum coils are highly valued. The stucco finish provides an extra layer of protection against wear and tear. 4. Signage and advertising: The signage and advertising industry extensively employs coil-stucco aluminum coils for creating outdoor signs, billboards, and displays. The stucco finish reduces glare and reflections, enhancing the visibility of the signs. Moreover, aluminum's weather-resistant nature makes it an appropriate choice for outdoor applications. 5. Packaging industry: The packaging industry also finds applications for coil-stucco aluminum coils. Aluminum, being non-toxic and non-reactive, proves to be a suitable material for packaging food and beverages. The stucco finish adds an appealing texture to the packaging material, making it visually attractive. 6. Industrial applications: Coil-stucco aluminum coils are used in various industrial applications, including the manufacturing of equipment, storage tanks, and processing systems. Aluminum coils are preferred in industries where excellent corrosion resistance, high thermal conductivity, and strength are crucial. In conclusion, coil-stucco aluminum coils possess diverse and extensive potential applications. The unique properties of aluminum, combined with the stucco finish, make these coils suitable for a wide range of industries, including construction, transportation, appliances, signage, packaging, and industrial applications.

- Q: What type of equipment is used to process aluminum coils?

- The type of equipment commonly used to process aluminum coils includes slitters, cut-to-length lines, roll formers, and annealing furnaces.

- Q: Are there any limitations or drawbacks of using aluminum coils?

- Yes, there are some limitations and drawbacks of using aluminum coils. One limitation is that aluminum coils tend to be more expensive than other coil materials, such as copper. This can make them less cost-effective for some applications, especially when large quantities of coils are required. Another drawback is that aluminum coils have a lower thermal conductivity compared to copper coils. This means that they may not transfer heat as efficiently, which can impact the overall performance of the system. In applications where heat transfer is critical, copper coils may be preferred. Aluminum is also more prone to corrosion compared to other metals. Although aluminum coils are typically coated or treated to enhance their resistance to corrosion, they can still be susceptible to damage in harsh environments or if the coating is compromised. This can lead to reduced efficiency and a shorter lifespan for the coils. Furthermore, aluminum coils may not be suitable for certain applications that require high strength or durability. Aluminum is a relatively soft metal, so it may not be able to withstand heavy loads or extreme conditions as effectively as other materials. Lastly, aluminum coils can be more challenging to repair or replace compared to other coil types. Due to their unique properties, specialized tools and techniques may be required for maintenance or repairs, which can add to the overall cost and complexity. Overall, while aluminum coils have their advantages, it is important to consider these limitations and drawbacks when selecting the appropriate coil material for a specific application.

- Q: Can aluminum coils be used in vacuum applications?

- Indeed, aluminum coils are capable of being employed in vacuum applications. Aluminum, being a frequently utilized substance in vacuum systems, possesses exceptional attributes including low outgassing, high thermal conductivity, and commendable corrosion resistance. Consequently, these qualities render aluminum coils suitable for a diverse array of vacuum applications, encompassing, but not restricted to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. Nevertheless, it is crucial to acknowledge that aluminum may react with particular gases or chemicals. Hence, it is imperative to carefully evaluate the specific necessities and compatibility of the vacuum application prior to employing aluminum coils.

Send your message to us

Customized High Quality Good Price 5083 Aluminum Prepainted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords