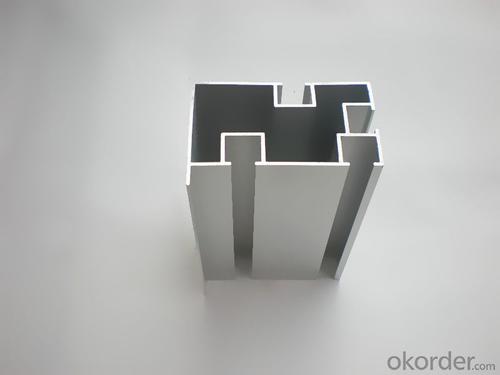

Custom Extruded Aluminum Profiles 6061 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Are aluminum profiles suitable for structural applications?

- Yes, aluminum profiles are suitable for structural applications. Aluminum is a lightweight and highly versatile material that offers excellent strength-to-weight ratio, corrosion resistance, and durability. These properties make it ideal for various structural applications such as architectural frameworks, bridges, aerospace structures, automotive frames, and industrial equipment. Additionally, aluminum profiles can be easily fabricated, welded, and joined, allowing for efficient construction and customization. With proper design and engineering considerations, aluminum profiles can provide the necessary strength and stability required for structural applications.

- Q: What are the advantages of using aluminum profiles in the telecommunications infrastructure?

- There are several advantages of using aluminum profiles in the telecommunications infrastructure. Firstly, aluminum profiles are lightweight yet strong, which makes them easy to transport and install. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity of the infrastructure in various weather conditions. Moreover, aluminum profiles can be easily customized and modified to fit specific project requirements, providing flexibility in design. Lastly, aluminum is a sustainable material, as it is 100% recyclable, which aligns with the growing focus on environmentally friendly practices in the telecommunications industry.

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Which aluminum profile is better here in Guangdong?

- 1 、 aluminum material2, Zhong Wang aluminum3 Asia Aluminum4, Hing Fat aluminum5, the phoenix aluminum aluminum6, the United States and aluminum7, vibration or aluminum8 、 Nanshan aluminum material9, pillars of aluminum10, South South aluminum

- Q: What are the aluminum profile manufacturers in Jiangsu?

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: Light aluminum is what mean?

- Extruded out only through aging treatment, without other surface treatment of aluminum (such as spraying, oxidation and other deep-processing)

- Q: This question asks for a list of various sizes and grades of aluminum profiles that can be found in the market.

- <p>Aluminum profiles are available in a wide range of sizes and grades to meet different application needs. Sizes are typically categorized by series, such as 1000, 2000, 3000, 5000, 6000, and 7000, which correspond to different alloy types. Each series has various thicknesses and cross-sectional dimensions. Grades are determined by the alloy composition and temper, with common grades including 1050, 6061, 6063, and 7075. The temper indicates the hardness and strength, with 'T' followed by a number (e.g., T6 for 6061-T6). Profiles can be flat bars, angles, channels, or complex shapes and are used in construction, automotive, aerospace, and other industries.</p>

- Q: How do you prevent galling or seizing with aluminum profiles?

- To avoid galling or seizing in aluminum profiles, several steps can be taken: 1. Apply lubricant: Use a suitable lubricant on the contact surfaces of the profiles. This reduces friction and heat, preventing galling or seizing. Be sure to choose a lubricant specifically made for aluminum to avoid any negative reactions. 2. Utilize surface treatments: Implement anodizing or protective coatings on the profiles. These treatments create a barrier between the profiles, minimizing direct metal-to-metal contact and decreasing the likelihood of galling or seizing. 3. Ensure proper design and materials: Make sure the profiles and their mating components have sufficient clearance and a proper fit. Avoid tight tolerances that can cause excessive contact pressure, which increases the risk of galling. Additionally, select materials with compatible hardness and avoid using dissimilar metals that may lead to galvanic corrosion. 4. Keep things clean: Maintain cleanliness by regularly cleaning the profiles and their mating surfaces, removing any dirt, debris, or contaminants. Foreign particles can increase friction and contribute to galling or seizing. 5. Implement regular maintenance: Establish a preventive maintenance program that includes periodic inspection, cleaning, and lubrication of the profiles. This helps identify any issues early on and ensures smooth operation over time. By following these preventive measures, the risk of galling or seizing in aluminum profiles can be minimized, resulting in longer-lasting performance.

- Q: The side wall of the box body is a heat sink, and the exposed end of the heat radiating fin can not damage the surface, and the inner surface is made of four M3h6 internal thread nut columns, which is welded? Or press riveting? Heat sink is extruded aluminum profile, the thickness of 5.5mm, slotted deep 2.5mm, how should this process? Do you have this nut column?

- Because the strength of the aluminum profile is too small, it is not suitable for thread matching. It is necessary to use screw sleeve (or wire screw sleeve) to form internal thread, or to solve the problem of strength with rivet nut;If it is for the wall thickness, is used for riveting nuts with the tool is riveter, or the number of small batch, with a large amount of manual, can use pneumatic riveter considering.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

Custom Extruded Aluminum Profiles 6061 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords