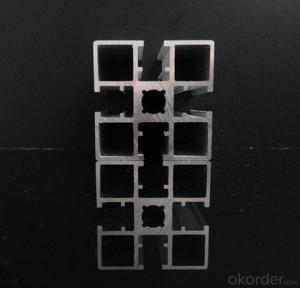

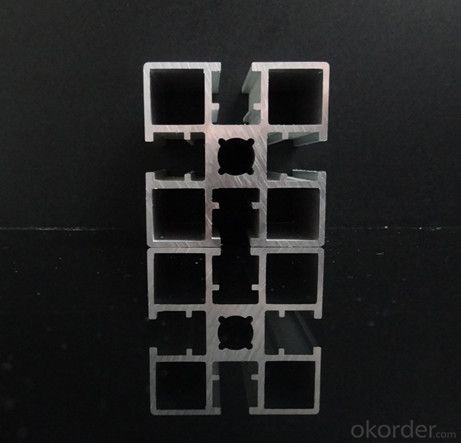

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 7005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Can aluminum profiles be used for framing mirrors?

- Indeed, mirrors can be framed using aluminum profiles. Aluminum, a lightweight and versatile material, lends a contemporary and polished appearance to any mirror frame. Its durability, resistance to corrosion, and simplicity in customization make it a favored choice in diverse industries such as architecture and interior design. With an array of shapes and finishes available, aluminum profiles provide limitless design options to suit various styles and decorations. Furthermore, the ease of installation and maintenance of aluminum frames further contributes to their popularity in both residential and commercial settings for framing mirrors.

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Can aluminum profiles be used in the production of agricultural machinery?

- Yes, aluminum profiles can be used in the production of agricultural machinery. Aluminum is a lightweight and durable material that can withstand harsh environmental conditions, making it suitable for various components and structures in agricultural machinery. Additionally, aluminum profiles offer flexibility in design and can be easily customized to meet specific requirements, enhancing the efficiency and performance of agricultural equipment.

- Q: Is it possible to utilize recycled aluminum from various sources to manufacture new aluminum profiles?

- <p>Yes, recycled aluminum can be used to create new aluminum profiles. The process involves melting down the recycled aluminum, which can then be reformed into new shapes and profiles. This not only conserves resources but also reduces energy consumption compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a wide range of applications, from construction to automotive industries.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: This question is asking about the various types of railings and staircases that can be constructed using aluminum profiles.

- <p>Aluminum profiles are versatile and can be used to create a variety of railings and staircases. Common types include glass railings, cable railings, frameless railings, and traditional aluminum baluster railings. Each type offers different aesthetic and functional benefits. Glass railings provide a sleek, modern look with unobstructed views. Cable railings are minimalistic and allow for maximum visibility. Frameless railings are characterized by their open design and are often used in commercial settings. Traditional aluminum baluster railings are sturdy and can be customized with various styles and finishes. These aluminum railings and staircases are known for their durability, low maintenance, and resistance to corrosion.</p>

- Q: This question seeks advice on making the aluminum profile production process eco-friendly.

- <p>To ensure an environmentally friendly production process for aluminum profiles, consider the following: Use recycled aluminum whenever possible to reduce the energy needed for production. Implement energy-efficient technologies and machinery in the production line. Minimize waste by optimizing production processes and recycling any aluminum scraps generated. Employ water-saving measures and treat any wastewater before discharge. Reduce emissions by using low-emission fuels and investing in pollution control equipment. Regularly monitor and assess the environmental impact of your operations and strive for continuous improvement.</p>

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: Are aluminum profiles suitable for roofing systems?

- Yes, aluminum profiles are suitable for roofing systems. Aluminum is a lightweight and durable material that offers numerous advantages for roofing applications. It is highly resistant to corrosion, making it suitable for various weather conditions and ensuring long-term performance. Aluminum profiles also have excellent thermal properties, reflecting heat and reducing energy consumption for cooling purposes. Additionally, aluminum is easy to work with, allowing for flexibility in design and installation. Overall, aluminum profiles are a popular choice for roofing systems due to their strength, longevity, and aesthetic appeal.

- Q: Are aluminum profiles suitable for use in exterior wall systems?

- <p>Yes, aluminum profiles are commonly used for exterior wall systems due to their durability, low maintenance, and resistance to corrosion and weathering. They offer a lightweight and strong alternative to traditional materials, and can be designed to provide thermal insulation and aesthetic appeal. Their versatility allows for various configurations and customizations, making them suitable for a wide range of architectural styles and requirements.</p>

Send your message to us

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords