CPC as Injection Coke Materials for Steel Plants

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.9

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

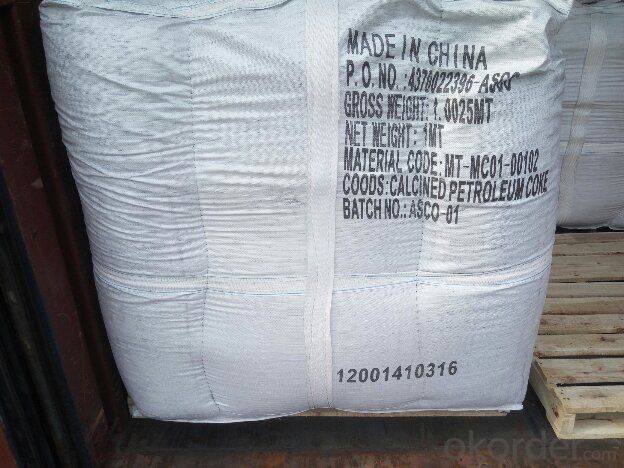

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: How does carbon dating work?

- The age of organic materials, such as plants, animals, and human remains, can be determined through the scientific technique known as carbon dating. This method relies on the continuous formation of carbon-14, a radioactive isotope of carbon, in the atmosphere due to cosmic rays. Carbon-14 is absorbed by living organisms through photosynthesis or consumption. The ratio of carbon-14 to stable carbon isotopes (carbon-12 and carbon-13) in the atmosphere remains relatively constant as living organisms maintain equilibrium by exchanging carbon-14 with the atmosphere through respiration or consumption. However, when an organism dies, it no longer takes in carbon-14, leading to the decay of existing carbon-14 at a predictable rate. Carbon-14 has a half-life of approximately 5,730 years, meaning that after this period, half of the carbon-14 in a sample will have transformed into nitrogen-14. By measuring the remaining carbon-14 in a sample, scientists can calculate the time that has passed since the organism's death. The carbon dating process involves several steps. Initially, a sample is collected from the organic material to be dated, which can include wood, bones, or textiles. The sample is then prepared for analysis by eliminating any impurities and converting it into a suitable form for measurement. Subsequently, the sample is exposed to a high-energy radiation source, such as a particle accelerator or a nuclear reactor. This exposure causes the carbon atoms in the sample to emit beta particles, which are small bursts of energy. These particles are detected and measured using sensitive instruments, enabling scientists to determine the remaining amount of carbon-14 in the sample. Finally, this information is utilized to calculate the age of the organic material. By comparing the ratio of carbon-14 to carbon-12 in the sample to the known ratio in the atmosphere, scientists can estimate the elapsed time since the organism's death. Carbon dating is an invaluable tool for archaeologists, paleontologists, and geologists. It allows for the accurate determination of the ages of ancient artifacts, fossils, and geological formations. This technique has revolutionized our understanding of human history and the natural world, providing us with invaluable insights into the past.

- Q: How is carbon used in the production of lubricants?

- Lubricants are produced using carbon in various ways. Base oil is one of the primary applications of carbon in lubricant production. Lubricants mainly consist of carbon-based molecules like mineral oils, synthetic oils, and vegetable oils. These oils are either obtained from crude oil or synthesized from other carbon-rich compounds. The base oil contains carbon atoms that form long chains or rings, offering exceptional lubricating properties. These carbon chains or rings possess high viscosity, reducing friction between moving parts. Consequently, this minimizes wear and tear, heat generation, and energy loss in different mechanical systems. Carbon is also utilized to create additives for lubricants. These additives are added to the base oil to improve its performance and provide additional advantages. For instance, graphite and molybdenum disulfide are carbon-based additives that deliver superior lubrication under extreme pressures and temperatures. They create a protective layer on the surface of moving parts, decreasing friction and preventing metal-to-metal contact. Moreover, carbon-based additives can enhance the oxidation resistance and anti-wear characteristics of lubricants. By introducing carbon molecules with specific functional groups, lubricants acquire the ability to form a protective film on metal surfaces. This film prevents corrosion and extends the lifespan of machinery. In conclusion, carbon plays a vital role in lubricant production. It acts as the base oil, providing viscosity and lubricating properties, and serves as an additive to optimize performance and safeguard machinery. Without carbon, the production of effective lubricants would be impossible.

- Q: What are the consequences of increased carbon emissions on vulnerable communities?

- Increased carbon emissions have severe consequences on vulnerable communities. Firstly, these communities often lack the resources and infrastructure to adapt to and mitigate the effects of climate change. As carbon emissions contribute to global warming, vulnerable communities are more likely to experience extreme weather events such as hurricanes, floods, and heatwaves. These events can result in displacement, loss of homes, and even loss of lives, disproportionately impacting those who are already marginalized. Furthermore, increased carbon emissions contribute to air pollution, which poses significant health risks to vulnerable communities. People living in low-income areas often reside near industrial plants or highways with high levels of emissions, leading to an increased risk of respiratory diseases, cardiovascular problems, and other health issues. Children, the elderly, and individuals with pre-existing health conditions are particularly vulnerable. The consequences of increased carbon emissions also extend to food security. Climate change affects agriculture and alters growing seasons, leading to reduced crop yields and food shortages. Vulnerable communities heavily reliant on subsistence farming or areas prone to droughts or floods face the risk of malnutrition and hunger. This exacerbates existing inequalities and can lead to social unrest and economic instability. In addition, vulnerable communities often rely on natural resources for their livelihoods, such as fishing, forestry, or tourism. The negative impacts of carbon emissions, like ocean acidification and coral bleaching, threaten these industries, resulting in job losses and economic decline. This further perpetuates the cycle of poverty and socio-economic vulnerability. Ultimately, increased carbon emissions disproportionately harm vulnerable communities by amplifying existing inequalities and exacerbating the challenges they face. It is crucial to address these consequences through climate mitigation efforts, adaptation strategies, and support for sustainable development.

- Q: What materials can be carbonitriding?

- Low temperature carbonitriding for high alloy tool steel, high-speed steel tools, etc., in temperature carbonitriding is under great pressure not only in carbon steel wear parts, high temperature carbonitriding is mainly used for medium carbon steel and alloy steel under great pressure.

- Q: What are the consequences of increased carbon emissions on forest ecosystems?

- Forest ecosystems experience significant consequences due to the increase in carbon emissions. One of the most notable effects is the modification of climate and weather patterns. The excessive presence of carbon dioxide in the atmosphere results in the retention of heat, leading to global warming. This rise in temperature can disrupt the delicate equilibrium of forest ecosystems. The warmer temperatures can cause shifts in the distribution and composition of tree species, as some may struggle to adapt to the changing conditions. Another outcome of the rise in carbon emissions is the acidification of rainwater. When carbon dioxide combines with water vapor, it creates carbonic acid, which can fall as acid rain. Acid rain has detrimental impacts on forest ecosystems, as it extracts vital nutrients from the soil and damages tree leaves and other vegetation. This weakens the overall health of the forest and makes it more susceptible to diseases and pests. Moreover, increased carbon emissions contribute to the intensification of wildfires. Higher temperatures and drier conditions provide an ideal environment for fires to spread and occur more frequently. Forests that have evolved to withstand natural fire patterns may struggle to cope with the increased intensity and frequency of these fires. This can result in the loss of biodiversity, destruction of habitat, and long-term degradation of forest ecosystems. Lastly, increased carbon emissions contribute to the phenomenon known as ocean acidification, where excess carbon dioxide is absorbed by the oceans. This acidification can impact the well-being of coastal and marine ecosystems, which are intricately connected to forest ecosystems. Many forest ecosystems, such as mangroves and salt marshes, serve as important nursery habitats for marine species. If these forest ecosystems decline due to carbon emissions, it can have cascading effects on the health and productivity of coastal and marine ecosystems. Overall, the increase in carbon emissions has wide-ranging consequences on forest ecosystems. It alters climate patterns, causes acid rain, intensifies wildfires, and affects coastal and marine ecosystems. These impacts not only harm the trees and vegetation within the forests but also disrupt the delicate balance of the entire ecosystem, resulting in the loss of biodiversity and long-term degradation. It is crucial to mitigate carbon emissions and promote sustainable practices to minimize these consequences and preserve the health and integrity of forest ecosystems.

- Q: The home wants to install electricity to warm the floor, the metal heating cable certainly won't use to have radiation, but is carbon system carbon fiber good or carbon crystal good?

- South Korea has a long history of electric heating, there is no domestic manufacturers have such technology! "Carbon crystal" is in the past two years, the domestic suddenly came out, it is estimated that dozens of homes!

- Q: How is carbon used in the production of graphite?

- The production of graphite relies heavily on carbon, which undergoes extreme heat and pressure to form its distinctive crystalline structure. The process commences with a high-quality carbon source, like petroleum coke or coal tar pitch, which is heated to eliminate impurities and transform it into pure coke. This coke is then ground into a fine powder and combined with a binder, typically pitch, to create a paste. The paste is molded into the desired shape, such as rods or blocks, and exposed to high temperatures in a furnace. The heat prompts the decomposition of the binder and the rearrangement of carbon atoms into hexagonal layers, characteristic of graphite. The furnace's high pressure aids in aligning the carbon layers, resulting in the formation of graphite crystals. Following the furnace process, the graphite undergoes further purification through treatments like chemical washing and acid leaching to eliminate any remaining impurities. Ultimately, the purified graphite is shaped into the final product, such as pencils, electrodes, or lubricants, using techniques like extrusion or machining. To summarize, the production of graphite involves subjecting a carbon source to high temperatures and pressures, leading to the creation of graphite crystals with its unique layered structure. This process enables the manufacturing of diverse graphite products, widely utilized in industries such as manufacturing, electronics, and energy.

- Q: How is carbon dioxide released into the atmosphere?

- Carbon dioxide is released into the atmosphere through a variety of natural and human activities. One of the primary sources of carbon dioxide is the burning of fossil fuels such as coal, oil, and natural gas for energy production. When these fuels are burned, carbon dioxide is released as a byproduct of combustion. This happens in power plants, factories, and vehicles that rely on these fossil fuels for energy. Deforestation and land-use changes also contribute to the release of carbon dioxide into the atmosphere. Trees absorb carbon dioxide through photosynthesis, and when they are cut down or burned, the stored carbon is released back into the atmosphere. This is particularly significant in tropical rainforests, where large amounts of carbon are stored in vegetation. Additionally, natural processes such as respiration and volcanic eruptions release carbon dioxide into the atmosphere. Respiration is the process by which living organisms, including humans and animals, breathe in oxygen and exhale carbon dioxide as a waste product. Volcanic eruptions release carbon dioxide stored in magma and rock formations. Overall, the release of carbon dioxide into the atmosphere is a combination of both natural and human activities. However, human activities, particularly the burning of fossil fuels and deforestation, have significantly increased the levels of carbon dioxide in the atmosphere, leading to the greenhouse effect and climate change.

- Q: How does carbon dioxide affect the pH of soil?

- Carbon dioxide can lower the pH of soil by reacting with water to form carbonic acid, which increases the acidity of the soil.

- Q: How are carbon fibers used in manufacturing?

- Carbon fibers are used in manufacturing for their exceptional strength, light weight, and high stiffness properties. They are commonly used as reinforcement materials in various industries such as aerospace, automotive, sports equipment, and wind energy. Carbon fibers are incorporated into composites to enhance the strength and durability of products, making them ideal for applications where weight reduction and structural integrity are crucial.

Send your message to us

CPC as Injection Coke Materials for Steel Plants

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.9

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches