corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Special Use: | Width: | Length: | |||

| color: |

Packaging & Delivery

| Packaging Detail: | corrugated color steel sheet /stainless color steel sheet seaworthy package with wooden pallet |

| Delivery Detail: | 20 days after receiving deposit |

Specifications

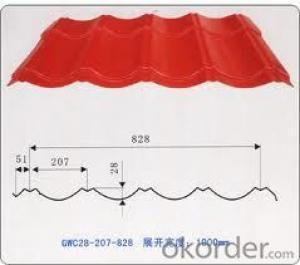

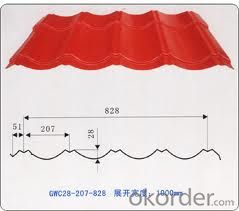

corrugated color steel sheet /stainless color steel sheet

1.Prime Quality,Low Price, Efficient Delivery.

2.Free sample.

corrugated color steel sheet /stainless color steel sheet

1. Base material: hot dipped galvanized steel

2. Width: available from 914MM to 1250MM

3. Width Tolerance: within 0.02MM

4. Thickness: available from 0.20MM to 0.80MM

5. Thickness Tolerance: within 0.15MM

6. Performance: Matte or GLossy

7. Color: according to RAL standard

8. Lacquer Coating thickness: according to customer needs

9. Supply capacity: 7000 Metric Ton per month

Our products has good performance on combining force and anti-erosion. We offer fine quality products and best price for our international customers. PPGI is light, beautiful and has good corrosion resistant performance, can be directly processed also, ppgi provides the construction, shipbuilding, vehicle manufacturing, furniture industry, and electrical industry a new material, while ppgi has good effects on the areas of replacing wood with steel, efficient construction, energy saving, prevent pollution etc.

Advantages of Our Prepainted Galvanized Steel Coil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Prepainted Galvanized Steel Coil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Coating Chief Feature

| Project | Pencil hardness | Reverse impact | T bending | Cupping test | MEK cleaning |

| Front/back | ≥ H/2H | ≥ 9J/6J | ≤ 3T/5T | ≥ 6mm/4mm | ≥ 100time/50time |

Structure of GI/PPGI

| Item | Thickness | Type | Feature |

| Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination (option) |

| Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

| Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

| Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

| Back coat |

5±2μm |

Epoxy | Corrosion resistance and adhesion to the substrate |

- Q: What are the different types of steel sheet alloys?

- There are several different types of steel sheet alloys, each with its own unique properties and applications. Some of the most common steel sheet alloys include: 1. Carbon Steel: This is the most basic type of steel and contains mainly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its strength and affordability. 2. Stainless Steel: Known for its corrosion resistance, stainless steel is made by adding chromium and other alloying elements to carbon steel. It is commonly used in applications where hygiene and durability are important, such as kitchen appliances, medical equipment, and architectural structures. 3. Galvanized Steel: This type of steel is coated with a layer of zinc to protect it from corrosion. Galvanized steel sheets are often used in outdoor applications, such as roofing, fencing, and automotive parts. 4. Alloy Steel: Alloy steel sheets are made by adding various alloying elements, such as nickel, chromium, and molybdenum, to carbon steel. These alloys enhance the strength, hardness, and wear resistance of the steel, making it suitable for applications in industries like aerospace, automotive, and machinery. 5. Tool Steel: Tool steel is specifically designed for the production of tools and dies. It is characterized by its high hardness, resistance to deformation, and ability to retain sharp edges. Tool steel sheets are commonly used in the manufacturing of cutting tools, drills, and molds. 6. Electrical Steel: This type of steel has been specially processed to have low magnetic losses and high electrical conductivity. Electrical steel sheets are used in the production of transformers, electric motors, and generators. These are just a few examples of the different types of steel sheet alloys available. Depending on the specific requirements of a project or application, engineers can choose the appropriate alloy to achieve the desired properties and performance.

- Q: Do the steel sheets have any sharp edges?

- Indeed, sharp edges can be found on steel sheets. Throughout their production, steel sheets frequently undergo cutting or shearing processes, thereby resulting in the presence of sharp edges. It is of utmost importance to exercise caution when dealing with steel sheets and to employ suitable protective gear, like gloves, while working with them, in order to prevent any harm arising from the sharp edges.

- Q: Can steel sheets be used for garage doors?

- Yes, steel sheets can be used for garage doors. Steel is a durable and strong material that provides security and protection for garage doors. It is commonly used due to its resistance to weather elements and its ability to withstand impact. Steel sheets are also available in various thicknesses and designs, offering flexibility in aesthetics and functionality for garage doors.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets possess remarkable strength and durability, attributes that render them exceptionally resistant to impact and damage. Their robust tensile strength enables them to endure substantial loads and withstand external forces without deformation or breakage. Thus, they find extensive use in critical applications that demand impact resistance, such as construction, automotive manufacturing, and industrial settings. Furthermore, steel sheets exhibit exceptional resilience against extreme temperatures, corrosion, and environmental factors, further enhancing their overall resistance to damage. However, it is worth noting that the degree of impact or damage resistance may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: What is the process of applying insulation materials to steel sheets?

- The process of applying insulation materials to steel sheets typically involves preparing the steel surface, applying an adhesive or bonding agent, and then affixing the insulation material to the steel using pressure or other mechanical means. This ensures a secure and effective insulation layer on the steel sheets.

- Q: Are steel sheets suitable for electrical grounding applications?

- Yes, steel sheets can be suitable for electrical grounding applications. Steel is a good conductor of electricity, and it can effectively dissipate electrical charges to the ground. Steel sheets are commonly used in grounding applications because of their durability, strength, and cost-effectiveness. They can be easily installed and provide a reliable connection to the earth, ensuring a safe path for electrical currents to flow in case of a fault or surge. However, it is important to ensure that the steel sheets are properly installed and maintained, as any corrosion or damage can affect their conductivity and effectiveness in grounding electrical systems.

- Q: What industries commonly use steel sheets?

- The industries that commonly use steel sheets include construction, automotive, manufacturing, aerospace, and shipbuilding.

- Q: Can steel sheets be used in the food processing industry?

- The food processing industry can utilize steel sheets for various purposes. Steel, being a highly versatile and durable material, finds extensive applications in this industry. Steel sheets are commonly employed in the construction of tables, work surfaces, shelves, cabinets, and containers, among other equipment and machinery. The suitability of steel sheets for the food processing industry arises from their unique properties. Firstly, steel exhibits resistance to corrosion, a crucial factor in an environment where food and liquids are constantly present. This resistance ensures that the steel sheets maintain their structural integrity and do not contaminate the food being processed. Secondly, steel is easily cleanable and sanitizable, a critical requirement for maintaining high standards of hygiene in the food processing industry. The smooth surface of steel sheets allows for easy wiping and prevents the accumulation of dirt, bacteria, and other contaminants that could compromise the quality and safety of the food. Furthermore, steel sheets possess exceptional strength and can withstand heavy loads and physical impacts. This makes them ideal for use in equipment and machinery that handle large quantities of food or require frequent movement or transportation. Additionally, steel is a non-porous material, meaning it does not absorb or retain odors, flavors, or stains from the food being processed. This property ensures that the steel sheets do not affect the taste or quality of the food. To summarize, steel sheets are widely utilized in the food processing industry due to their durability, corrosion resistance, ease of cleaning, and non-porous nature. They provide a reliable and hygienic solution for constructing essential equipment and machinery in food processing operations.

- Q: Are steel sheets resistant to mold and mildew?

- Yes, steel sheets are highly resistant to mold and mildew due to their non-porous nature and lack of organic materials that promote their growth.

- Q: Are the steel sheets coated with any protective material?

- Indeed, a protective material is applied to the steel sheets, ensuring their durability and resistance against corrosion. Typically, this coating is added to the steel sheets to enhance their strength and safeguard them from external elements such as moisture, chemicals, and adverse weather conditions. It acts as a formidable shield, preventing the steel from rusting or deteriorating. The specific protective material used may vary depending on the intended purpose and specific requirements. However, a commonly employed option is a layer of zinc or zinc-alloy coating, known as galvanized coating. This particular coating offers exceptional defense, significantly prolonging the lifespan of the steel sheets and rendering them suitable for a wide range of industries and applications.

Send your message to us

corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords