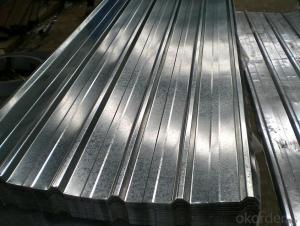

Aluminum Sheets in Indiana - Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Corrugated Aluminum Tile in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

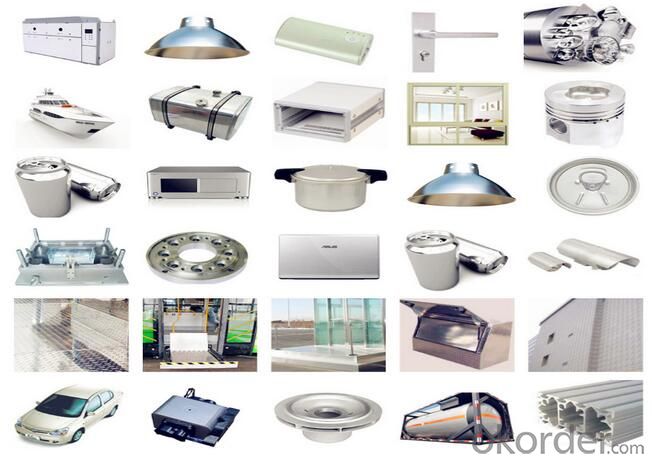

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can 101 aluminum sheets be powder coated?

- Yes, 101 aluminum sheets can be powder coated.

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- According to my farrier, aluminum shoes are harder to put on because they are softer than steel and they are easier to damage while shaping them for your horse's foot. He also says that aluminum shoes wear down faster than steel shoes, so if you are working a horse in a highly competitive sport, it's better to put steel shoes on. Most racehorses have aluminum shoes put on simply because they're lighter, but if you don't want to be changing the shoes every two weeks, or can't afford to, then steel shoes are the best way to go.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. Aluminum is a popular material for roofing because it is lightweight, durable, and resistant to corrosion. It is also non-combustible, making it a safer option for roofing. Aluminum sheets are easy to install and maintain, and they can withstand harsh weather conditions such as heavy rain, snow, and wind. Additionally, aluminum is a sustainable material, as it is 100% recyclable, making it an environmentally friendly choice for roofing. Overall, aluminum sheets provide a long-lasting and reliable roofing solution for both residential and commercial buildings.

- Q: What are the dimensions and thickness options for aluminum sheets?

- The dimensions and thickness options for aluminum sheets can vary depending on the supplier and specific requirements. Generally, aluminum sheets are available in various dimensions, such as 4ft x 8ft, 4ft x 10ft, or custom sizes. In terms of thickness, aluminum sheets can range from as thin as 0.006 inches (0.15 mm) to as thick as 0.25 inches (6.35 mm) or even thicker for specialized applications. It is important to consult with the supplier or manufacturer to determine the exact dimensions and thickness options available for aluminum sheets.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: Aluminum plate 90 degree bending, why cracking?

- Should be the aluminum sheet material and status is wrong, I wonder what brand aluminum plate?.Use 1060 Aluminum plate, condition: soft, 90 degree bending, won't crack

- Q: Are aluminum sheets suitable for structural applications?

- Yes, aluminum sheets are suitable for structural applications. Aluminum is a lightweight and strong material, making it ideal for use in various structural applications. It has a high strength-to-weight ratio, which means that it can provide significant strength while keeping the overall weight of the structure low. This characteristic makes aluminum sheets particularly suitable for applications where weight is a critical factor, such as in aerospace, automotive, and marine industries. Additionally, aluminum sheets offer excellent corrosion resistance, which is important for structures that are exposed to harsh environmental conditions or moisture. They are also highly durable and have good thermal and electrical conductivity. These properties make aluminum sheets suitable for a wide range of structural applications, including building facades, roofing, curtain walls, bridges, shipbuilding, and electrical enclosures. Moreover, aluminum sheets are easy to work with, as they can be easily cut, formed, and welded. This flexibility in fabrication allows for the creation of complex and customized structural components. Aluminum also has a natural oxide layer that provides protection against corrosion, reducing the need for additional coatings or treatments. However, it is important to consider the specific requirements and loads of each structural application before choosing aluminum sheets. While aluminum is strong, it may not be suitable for heavy-load-bearing applications where steel or other materials may be more appropriate. Proper engineering and design considerations should be taken to ensure the structural integrity and safety of the application.

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used for aircraft manufacturing. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for constructing various components of an aircraft. It is strong enough to withstand the stresses and strains experienced during flight, while also being malleable enough to be formed into various shapes and sizes. Additionally, aluminum sheets can be easily joined together using various welding techniques, allowing for efficient and effective assembly of aircraft structures. Overall, the use of aluminum sheets in aircraft manufacturing helps to ensure a balance between strength, weight, and durability, making it a preferred material in the aerospace industry.

- Q: Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is a highly efficient conductor of heat, making it an ideal material for heat exchangers. Its high thermal conductivity allows for excellent heat transfer between fluids, resulting in efficient heat exchange. Additionally, aluminum sheets are lightweight, corrosion-resistant, and have good mechanical properties, further contributing to their suitability for heat exchanger applications.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily bent, shaped, or formed without cracking or breaking. This property makes it an ideal choice for various applications where flexibility and customization are required. Aluminum sheets can be bent using various methods, such as using a brake press, roll forming, or by hand using specialized bending tools. The level of bendability may vary depending on the thickness and grade of the aluminum sheet, but in general, aluminum is known for its excellent formability and ability to be shaped into different configurations.

Send your message to us

Aluminum Sheets in Indiana - Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords