Corrugated Aluminum Roofing Sheets - Aluminium Prepainted Sheet - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

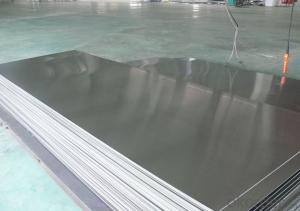

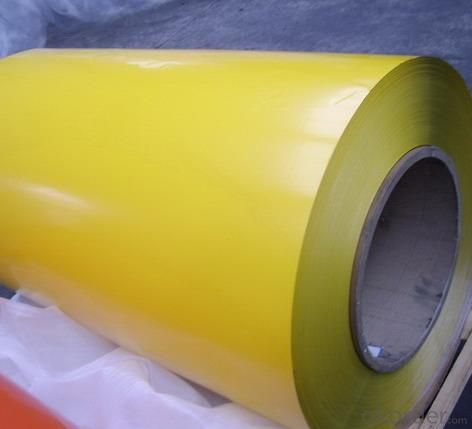

Structure of Prepainted Aluminum Coil Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminum Coil:

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Images of Prepainted Aluminum Coil.

Prepainted Aluminum Coil Specification :

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001.ISO14001.OHSAS18001 |

| Thickness | 0.16mm-0.7mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | customized |

| Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

FAQ of Prepainted Aluminium Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 5000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: What is the typical tensile strength of aluminum sheets?

- The typical tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20,000 to 45,000 pounds per square inch (psi).

- Q: Are the aluminum sheets suitable for signage or advertising purposes?

- Aluminum sheets are an excellent choice for signage and advertising purposes due to their high suitability. The versatility and durability of aluminum make it resistant to rust, corrosion, and weathering, which is ideal for outdoor use. Furthermore, its lightweight nature facilitates effortless installation and transportation, while the smooth surface adds a touch of professionalism and sophistication. The customizable nature of aluminum sheets allows for easy cutting, shaping, and engraving, enabling designers to create captivating signs and advertisements. Additionally, aluminum sheets can be directly printed on or laminated with vinyl to achieve vibrant and long-lasting graphics. In summary, the remarkable properties of aluminum make it the perfect material for signage and advertising purposes.

- Q: Do these frames rust? For example here is a link. But I am genuinely curious because in swimming pools, the hand rails going into the swimming pool have the same finish as this bike frame and they have white corrosion marks. Thank you in advanced

- Rust refers to the oxidation of iron, so no it doesn't rust. Aluminium oxidates rapidly which usually increases its corrosion resistance. 6061 is a pretty standard aluminium alloy, which shouldn't corrode under normal circumstances. Certainly not in a well designed and maintained bicycle. Things that could decrease the corrosion resistance of your aluminium bike include: - contact with other metals that have a higher valence (+ contact with water). Could be caused by a poorly designed bike, but not very likely. - contact with chemicals/salts/alkalis - narrow spots (where water could be trapped) caused by poor design, production faults or a damaged surface. Corrosion in your swimming pool could be caused by the chemicals you use to kill the bacteria in the pool. How do you know it is the same material though?

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- In aerospace applications, aluminum sheets are commonly used due to their lightweight and high strength properties. The thickness of aluminum sheets used in aerospace applications can vary depending on the specific requirements of the component or structure being fabricated. Commonly used thicknesses for aluminum sheets in aerospace applications range from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm). These thicknesses are selected based on factors such as the desired strength-to-weight ratio, structural integrity, and the specific application or component being manufactured. Thinner aluminum sheets, such as those with a thickness of 0.016 to 0.040 inches, are often used for lightweight structures, interior components, and non-critical parts. These thinner sheets provide the necessary strength while minimizing weight. For more structural components, thicker aluminum sheets are employed. Thicknesses between 0.040 and 0.125 inches are commonly used for structural elements like floor panels, bulkheads, and wing ribs. These sheets offer increased strength and rigidity for supporting the aircraft's weight and managing the stresses experienced during flight. In certain cases, even thicker aluminum sheets may be used, ranging from 0.125 to 0.25 inches, for heavy-duty structural components or areas where additional strength is required. These thicker sheets are utilized in critical parts such as landing gear components, wing spars, and engine mounts to ensure the necessary structural integrity and load-bearing capability. It is important to note that these are general ranges, and the specific thickness requirements may vary depending on the aircraft type, design specifications, and the particular application within the aerospace industry.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Indeed, aluminum sheets prove to be a fitting material for the production of aircraft wings. In the aerospace sector, aluminum is extensively utilized owing to its remarkable strength-to-weight ratio, ability to resist corrosion, and high thermal conductivity. These attributes render it an ideal option for fabricating aircraft components that are both lightweight and robust, such as wings. Aluminum sheets can be easily molded, fused, and processed, enabling the creation of intricate wing designs. Furthermore, the low density of aluminum aids in reducing the overall weight of the aircraft, thereby enhancing fuel efficiency and maneuverability. In summary, the utilization of aluminum sheets in the manufacture of aircraft wings is a prevalent and validated practice within the aviation industry.

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

- Q: What are the common surface treatments for aluminum sheets used in outdoor applications?

- Aluminum sheets used in outdoor applications can be treated in various ways to improve their durability, resistance to weathering, and appearance. Three common surface treatments include anodizing, powder coating, and PVDF coating. Anodizing is a process that involves immersing the aluminum sheet in an electrolyte solution and applying a current to create a thick oxide layer on its surface. This layer provides excellent protection against corrosion, UV rays, and weathering, making anodized aluminum sheets suitable for outdoor use. Powder coating, on the other hand, is a dry finishing process where a powdered paint is electrostatically applied to the aluminum sheet. The sheet is then heated to melt the powder and form a smooth and durable coating. Powder coating offers exceptional resistance to weathering, scratches, and fading, making it perfect for outdoor applications. It also provides a wide range of color options and gives the sheet a uniform and attractive appearance. Lastly, PVDF coating is a high-performance coating that combines resin with ceramic particles. It is applied as a liquid and cured at high temperatures to form a continuous and protective film on the aluminum sheet. PVDF coatings are known for their exceptional resistance to fading, chalking, and exposure to chemicals, making them suitable for harsh outdoor environments. They also retain their color well, are highly durable, and offer great resistance to UV rays. All of these surface treatments enhance the durability, weather resistance, and aesthetic appeal of aluminum sheets, making them ideal for outdoor applications in industries such as architecture, signage, transportation, and marine. When selecting a surface treatment, it is crucial to consider the specific requirements of the outdoor application, including factors like durability, color options, and resistance to weathering and corrosion.

- Q: Can aluminum sheets be anodized for added durability?

- Yes, aluminum sheets can be anodized for added durability. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum. This layer not only enhances the appearance of the material but also increases its resistance to corrosion, wear, and scratches. Anodizing provides a hard, durable, and long-lasting finish, making it an ideal choice for various applications where durability is crucial, such as in construction, automotive, aerospace, and electronics industries. Additionally, anodized aluminum sheets can be dyed in various colors, further enhancing their aesthetic appeal while maintaining their durability.

- Q: This question asks for various methods through which aluminum sheets can be recycled and repurposed.

- <p>Aluminum sheets can be recycled and reused in several ways: 1. Melting and Reformation: The most common method is to melt down the aluminum and reform it into new products. 2. Mechanical Recycling: This involves shredding and compacting the aluminum sheets to be used as raw material in new products. 3. Energy Recovery: The heat generated from burning aluminum can be used to produce energy. 4. Alloying: Aluminum can be combined with other metals to create new alloys with different properties. 5. Reuse in Construction: Aluminum sheets can be reused in construction projects, such as facades or roofing. 6. Manufacturing: They can be used in manufacturing processes to create new aluminum products like cans, foils, and automotive parts. Proper recycling of aluminum reduces environmental impact and conserves resources.</p>

Send your message to us

Corrugated Aluminum Roofing Sheets - Aluminium Prepainted Sheet - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords