High Quality Pre-painted Aluminum Composite Sheets Los Angeles - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Sheet Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

It is widely used in architecture (corrugated sheet and light steel structure of houses; transporting industry (automobile roof, vehicle & ship separator, container); household light products (shell of refrigerator, cooler, washing machine, air conditioner, etc), as well as metal sheet processing products and furniture.

Main Features of Prepainted Aluminium Sheet:

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

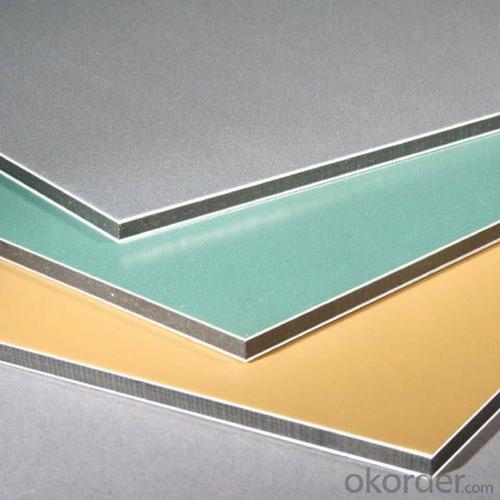

Images of Prepainted Aluminium sheet:

Prepainted Aluminium Sheet Specification:

Specification of prepainted aluminum coil sheet | |||

Substrates: | Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. | ||

Thickness: | 0.08-4.0mm | ||

Width: | << span="">1800mm | ||

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm | ||

Coating thickness: | PVDF >=25micron POLYESTER>=18micron | ||

Color standard: | E < 2 or it is not obvious by eyeballing | ||

Pencil hardness: | > 2HB | ||

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) | ||

Bend stength: | >100 times | ||

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) | ||

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change | ||

FAQ of Prepainted Aluminium Sheet:

What's your package style?

Standard export packing as follow:

Plastic film wrapped inside and carton packing. Wooden pallet with steel strip tied.

Buyers can slao choose to pay for wooden case packing, which enables safer and more room saving in loading.

Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can aluminum sheets be used for insulation cladding?

- Yes, aluminum sheets can be used for insulation cladding. Aluminum is a popular choice for cladding material due to its durability, lightweight nature, and resistance to corrosion. It acts as a protective layer for insulation materials, providing thermal insulation, weather resistance, and aesthetic appeal to buildings.

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: What are the different forming methods for aluminum sheets?

- There are several different forming methods that can be used to shape aluminum sheets. These methods include: 1. Roll Forming: This process involves passing the aluminum sheets through a series of rollers that gradually shape the material into the desired form. Roll forming is often used to create long, continuous shapes such as channels or rails. 2. Press Forming: Press forming uses hydraulic or mechanical presses to apply force to the aluminum sheet, creating the desired shape. This method is commonly used for forming complex shapes with tight tolerances. 3. Stretch Forming: In stretch forming, the aluminum sheet is clamped at its edges and then stretched over a die, causing the material to conform to the shape of the die. This method is often used to produce curved or contoured parts. 4. Deep Drawing: Deep drawing involves placing a blank of aluminum sheet into a die and then using a punch to force the material into the die cavity, creating a hollow shape. This method is commonly used to produce cylindrical or box-shaped parts. 5. Hydroforming: Hydroforming uses hydraulic pressure to shape the aluminum sheet against a die. This method is particularly useful for producing complex, intricate shapes with smooth surfaces. 6. Incremental Sheet Forming: In incremental sheet forming, a CNC machine moves a small tool over the surface of the aluminum sheet, gradually shaping it by applying localized pressure. This method is often used for prototyping or small-scale production. These forming methods offer different advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and volume of production.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a lightweight and durable material that is commonly used for this purpose due to its resistance to rust and corrosion. Additionally, aluminum can be easily shaped and customized to meet specific design requirements, making it a popular choice for balcony railings.

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: Are aluminum sheets suitable for HVAC systems?

- Yes, aluminum sheets are suitable for HVAC systems. Aluminum is a lightweight and durable material that provides excellent thermal conductivity, making it ideal for use in HVAC systems. It is commonly used for making ductwork, heat exchangers, and fins in air conditioning units. Aluminum sheets are corrosion-resistant, which is advantageous in environments with high humidity or exposure to moisture. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for HVAC systems. Overall, aluminum sheets offer numerous benefits and are widely used in the HVAC industry.

- Q: Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, preventing further corrosion. This makes it ideal for use in saltwater environments where the risk of rusting and corrosion is high. Additionally, aluminum is lightweight, durable, and has a high strength-to-weight ratio, making it suitable for various marine applications such as boat hulls, shipbuilding, offshore platforms, and other marine structures.

- Q: Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

Send your message to us

High Quality Pre-painted Aluminum Composite Sheets Los Angeles - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords