Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

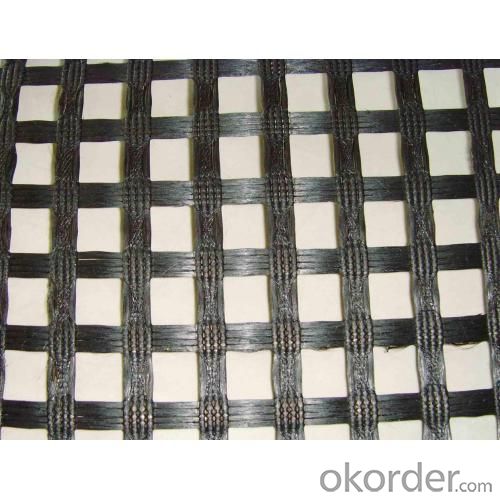

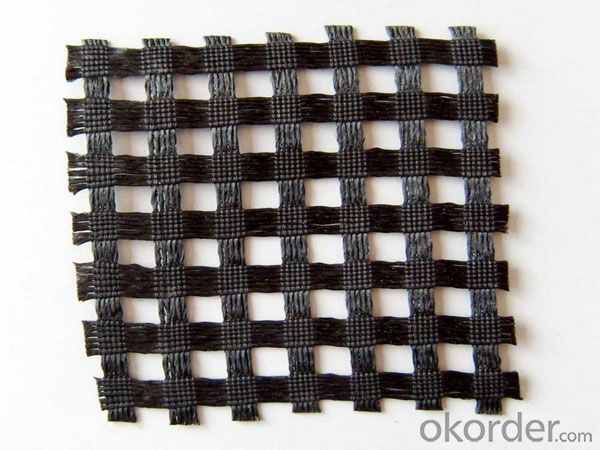

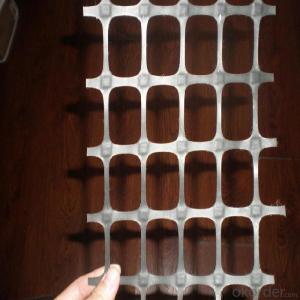

Structure of Corrosion Resistant Fiberglass Geogrid Description:

Corrosion Resistant Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Used for engineering reinforcement,10%,13% elongation,50x50mm holes size.

Main Features of Corrosion Resistant Fiberglass Geogrid:

Fiberglass Geogrid Improve roadbed bearing capacity,enlarge road lifetime.

Prevent road collapse and crack

Fiberglass Geogrid maninly applied in strengthen soft ground of rail and road

Could replace steel-plastic geogrid in coal mine.

Corrosion Resistant Fiberglass Geogrid Images

Corrosion Resistant Fiberglass Geogrid Specification:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are designed to provide stability and strength to weak or unstable soil, making them ideal for reinforcing soft ground. They are commonly used in various civil engineering applications, such as road and railway construction, to enhance the load-bearing capacity of the soil and prevent ground movement or settlement.

- Q: What are the advantages of using geogrids in ground improvement for seismic stability?

- Geogrids offer several advantages when used in ground improvement for seismic stability. Firstly, they provide increased strength and stability to the soil, enhancing its ability to withstand seismic forces. Geogrids can effectively distribute and dissipate the energy generated during an earthquake, reducing the risk of soil liquefaction and ground failures. Additionally, geogrids can improve the bearing capacity of the soil, allowing it to support heavier loads without experiencing settlement or failure. Furthermore, geogrids are easy to install and cost-effective compared to other ground improvement techniques, making them a viable solution for seismic stability in various construction projects.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize weak soil, enhance load-bearing capacity, and prevent soil erosion. They are effective in retaining walls, embankments, road construction, and other ground improvement applications.

- Q: Introduction of steel plastic grille

- Construction technology of steel plastic grille

- Q: What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it can impact the overall stability and strength of the geogrid system. Proper spacing ensures that the geogrids are installed at the correct intervals, allowing them to distribute the load evenly and provide effective reinforcement. Incorrect spacing can lead to inadequate reinforcement, reduced performance, and potential failure of the geogrid system.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on factors such as the quality of the materials used, the specific application, and the environmental conditions. However, geogrids are designed to have a long service life and can often last for several decades under normal conditions.

- Q: How do geogrids enhance the stability of landfill slopes?

- Geogrids enhance the stability of landfill slopes by providing reinforcement and preventing soil erosion. They are placed within the slopes to distribute and transfer the weight of the landfill, reducing the stress on the soil. This helps to prevent slope failure and maintain the integrity of the landfill structure. Additionally, geogrids increase the friction between soil particles, improving the overall stability of the slope.

- Q: Are geogrids suitable for use in ground reinforcement for residential developments?

- Yes, geogrids are suitable for use in ground reinforcement for residential developments. Geogrids provide effective soil stabilization and reinforcement, enhancing the stability and load-bearing capacity of the ground. They are durable, cost-effective, and can be easily installed, making them a practical choice for residential projects.

- Q: What is the overlap length of the two-way geogrid? What is the overlap length of geotextiles?

- It should be 20cm to 40cm, it's a little longer

- Q: How do geogrids prevent differential settlement?

- Geogrids prevent differential settlement by distributing the load and enhancing the stability of soil by providing reinforcement. They improve the overall strength and stiffness of the soil, reducing the likelihood of differential settlement occurring.

Send your message to us

Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords