Geogrids Price for Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

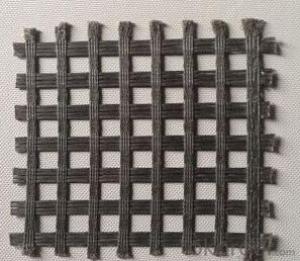

Structure of Fiberglass Geogrid Description:

Fiberglass Geogrid is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Fiberglass Geogrid :

Fiberglass Geogrid is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.

Fiberglass Geogrid is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed

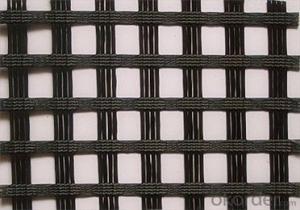

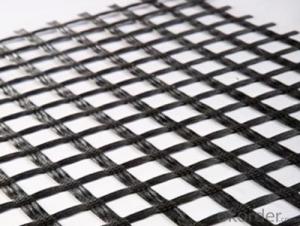

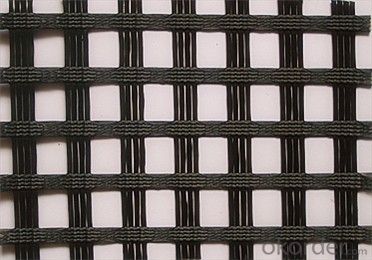

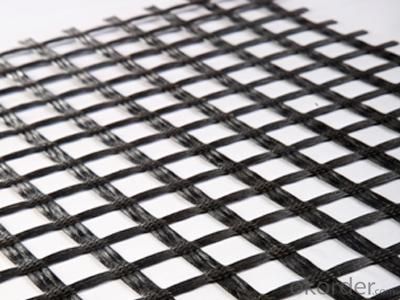

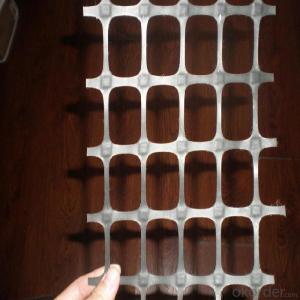

Fiberglass Geogrid Images

Fiberglass Geogrid Specification:

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How much is the geogrid return

- This is based on the specific size of the size of the size of the geogrid length and width of the mesh size to determine

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge piers?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge piers. Geogrids are commonly used in such applications to provide additional strength, stability, and load-bearing capacity to the soil, enhancing the performance and longevity of the bridge piers.

- Q: What are the factors affecting the design of geogrid-reinforced structures?

- The factors affecting the design of geogrid-reinforced structures include soil type and properties, slope stability, loading conditions, environmental factors, and the desired structural performance.

- Q: How much investment is needed for the grid cloth on the production site

- You need to spread the production capacity of a loom one day about 1K meters, a width of 1 meters looms, about 4500 a, 2 meters in width of about 12000 a, and other auxiliary facilities, in addition to loom workshop. About 100 thousand.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and stability to the soil. They distribute the load over a larger area, preventing localized settlement and ensuring a more uniform settlement across the structure. This helps to maintain the integrity and stability of the structure, reducing the risk of differential settlement and potential damage.

- Q: Are geogrids resistant to hydrolysis?

- Yes, geogrids are generally resistant to hydrolysis.

- Q: Can geogrids withstand heavy loads?

- Yes, geogrids are designed to withstand heavy loads. They are made from high-strength materials and have a structural design that allows them to distribute and transfer loads effectively. Geogrids are commonly used in various applications such as road construction, retaining walls, and slope stabilization, where they provide reinforcement and increase the load-bearing capacity of the soil or aggregates they are installed with.

- Q: Self adhesive fiberglass geogrid price 1m2 how much money

- Generally more than the usual ordinary fiberglass grille 3 cents or so, I am a manufacturer of sales, if necessary, you can chat with me, thank you

- Q: Can geogrids be used in reinforcement of embankments on expansive clays?

- Yes, geogrids can be used in the reinforcement of embankments on expansive clays. Geogrids are commonly used in such scenarios to improve the stability and performance of embankments by providing tensile strength and preventing soil movement. By distributing the load and reducing the potential for settlement, geogrids effectively reinforce embankments on expansive clays.

- Q: Geogrid GSZ 100 50/PP what does it mean

- GSZ is the steel plastic grille

Send your message to us

Geogrids Price for Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords