High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

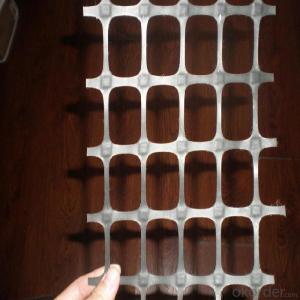

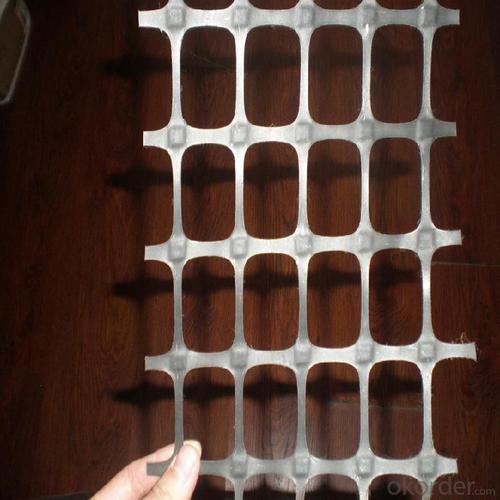

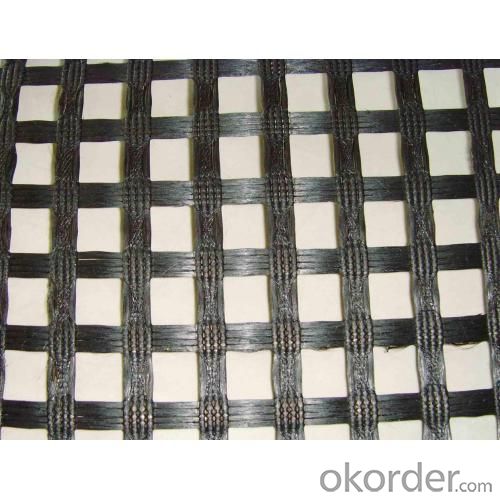

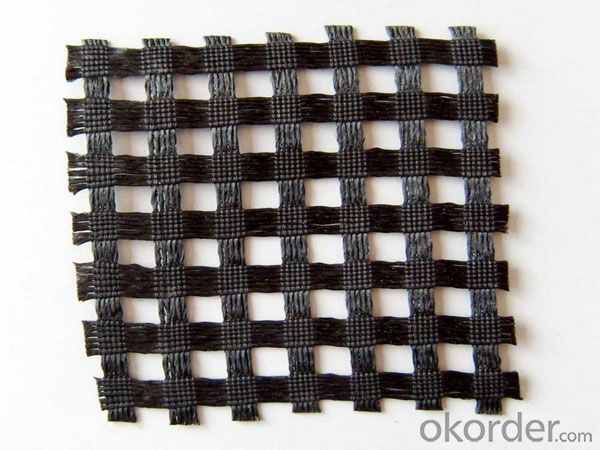

Structure of High Tensile Strength Fiberglass Geogrid Description:

High Tensile Strength Fiberglass Geogrid is a kind of reinforcement product, Both warp and weft directions are high tensile strength and low elongation. It can be used in the construction o railway, highway, bridge, wharf, etc., which require firm-quality construction materials for security purpose. Therefore basalt fiber geogrid is an ideal material for construction.

Main Features of High Tensile Strength Fiberglass Geogrid:

High strength, high modulus and low elongation.

Aging resistance and high tensile strength.

Pre-designed and easily combing with gravel and soil

Could replace steel-plastic geogrid in coal mine.

High Tensile Strength Fiberglass Geogrid Images

High Tensile Strength Fiberglass Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids resistant to chemicals and environmental degradation?

- Yes, geogrids are generally resistant to chemicals and environmental degradation. They are designed to withstand exposure to various chemicals, including acids, alkalis, and solvents, without significant degradation. Additionally, geogrids are typically manufactured using high-strength polymers that are resistant to UV radiation, biological degradation, and other environmental factors, ensuring their long-term durability and performance.

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by providing reinforcement and stabilization to the layers of the pavement structure. They distribute and transfer the load from the surface to the underlying layers, reducing the stresses and preventing the formation of cracks and deformations. Geogrids also enhance the interlock between the different pavement layers, increasing the overall strength and load-bearing capacity of the road.

- Q: Should the municipal geogrid be included in the area of overlap, and, if necessary, the proportion of the area to be included?

- The measurement of municipal geogrid shall not be included in the overlap area

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Natural bentonite can be divided into two categories: sodium and calcium. Bentonite has the characteristics of water swelling and bentonite waterproof blanket. General calcium bentonite expansion, the expansion of its volume is only about 3 times, while sodium bentonite in water adsorption weight five times of water, the volume expansion to more than 15-17 times the original, the sodium bentonite lock in the middle of the two layers of geosynthetic materials, maintenance and the role of strengthening, so that GCL is the shear strength of a whole.

- Q: How to restore the plastic geogrid after being destroyed?

- 2 the surface of the bearing surface of the geosynthetics shall be leveled and compacted, and the hard and protruding surface shall be removed.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength and stability. They act as a reinforcement layer within the tube, preventing deformation and maintaining the desired shape. Geogrids also help distribute the load evenly, increasing the overall stability and durability of the geotextile tube system.

- Q: Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids provide additional reinforcement to the soil, improving stability and preventing potential wall failure. They are commonly used to increase the strength and durability of retaining walls in residential settings, ensuring long-term performance and safety.

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are commonly used in road construction for reinforcement of the soil, improving the stability and load-bearing capacity of the road. They are often used to reduce cracking and rutting, enhance pavement performance, and increase the overall lifespan of the road.

- Q: What is the name of the geotextile woven from polyester and polyester threads?Should be with a flat woven out, like polyester yarn is double stranded and

- Polyester woven geotextile

- Q: Can geogrids be used in soil reinforcement for landslide mitigation?

- Yes, geogrids can be used in soil reinforcement for landslide mitigation. Geogrids are commonly used to enhance the stability and strength of soil, including in slope stabilization and landslide prevention. They are placed within the soil mass to provide reinforcement and improve its load-bearing capacity, reducing the risk of landslides.

Send your message to us

High Tensile Strength Fiberglass Rail Track Reinforcement Geogrids with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords