Copper Aluminum Coils Lennox Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

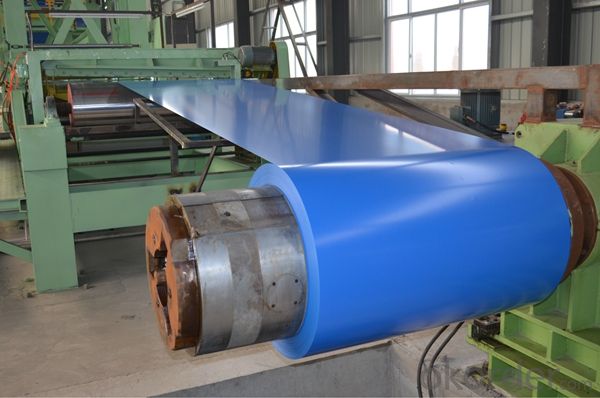

5. Image of Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

6. Package and shipping of Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of aluminum composite doors?

- Yes, aluminum coils can be used in the production of aluminum composite doors. Aluminum coils are often used as the primary material for manufacturing aluminum composite doors due to their durability, lightweight nature, and corrosion resistance. These coils are typically processed and shaped into different components of the door, such as panels, frames, and profiles, to create a strong and aesthetically appealing final product.

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Are aluminum coils suitable for lightweight applications?

- Yes, aluminum coils are suitable for lightweight applications. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal choice for lightweight applications where weight reduction is crucial, such as in the automotive, aerospace, and packaging industries.

- Q: Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum is a versatile material that can be coated or painted to achieve various finishes and colors. The surface of aluminum coils can be prepared through a process called pre-treatment, which involves cleaning, etching, and applying a primer. This prepares the surface for painting or printing. Painting aluminum coils involves applying a coating system that typically consists of a primer, a color coat, and a topcoat for protection. The paint can be applied using various methods such as spraying, roll coating, or coil coating. Coil coating, in particular, is a commonly used method where the paint is applied to the coil before it is formed into the desired shape. This ensures a uniform and consistent finish. Printing on aluminum coils is also possible using different techniques such as screen printing, digital printing, or lithography. These methods allow for detailed designs, patterns, or even photographs to be printed onto the surface of the aluminum coil. It is important to note that the choice of paint or printing method may depend on the specific requirements of the application, such as durability, weather resistance, or aesthetic preferences. Additionally, proper surface preparation, selection of suitable coatings, and adherence to recommended application guidelines are essential for ensuring a successful and long-lasting paint or print finish on aluminum coils.

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Aluminum coils come with limitations and restrictions that need to be taken into account. Some of the key limitations are as follows: 1. Corrosion: Aluminum is prone to corrosion, especially when exposed to certain chemicals or environments. This means it may not be suitable for applications where it will encounter corrosive substances or highly corrosive environments. 2. Strength: Although aluminum is lightweight, it lacks the strength of metals like steel. This limits its use in applications requiring high strength or load-bearing capabilities. 3. Temperature sensitivity: Aluminum has a lower melting point compared to other metals, which can be a drawback in applications involving high temperatures. It may not be suitable for certain industrial or high-temperature environments. 4. Electrical conductivity: While aluminum has good electrical conductivity, it falls short of copper's conductivity. This can limit its use in applications requiring high electrical conductivity, such as electrical wiring or power transmission. 5. Cost: Aluminum can be more expensive than other metals, making it less favorable in cost-sensitive applications. In such cases, alternative materials may be preferred. 6. Formability: Compared to some other metals, shaping or forming aluminum coils can be challenging. This restricts their use in applications that demand complex shapes or tight tolerances. When selecting aluminum coils for a specific purpose, it is crucial to consider these limitations and restrictions. A careful evaluation of the particular requirements and constraints will help determine whether aluminum coils are suitable or if alternative materials should be considered.

- Q: Can aluminum coils be used in architectural applications?

- Aluminum coils, indeed, find application in architectural projects. The construction industry frequently employs aluminum due to its adaptability, endurance, and ease of manipulation. Architects often make use of aluminum coils for roofing, cladding, and facades, thanks to their malleability in creating diverse forms and proportions. Furthermore, these coils can be coated with various finishes to improve their visual appeal and safeguard against weathering and discoloration. Ultimately, given their blend of utility, attractiveness, and durability, aluminum coils have become a favored option for architectural purposes.

- Q: This question asks about the environmental impact of aluminum coils, including potential effects on the ecosystem and human health.

- <p>Aluminum coils, when produced and used responsibly, have minimal environmental impact. However, improper disposal or manufacturing can lead to pollution. Aluminum production requires significant energy, contributing to greenhouse gas emissions. During manufacturing, if not managed properly, can release harmful substances into the air and water. Yet, aluminum is highly recyclable, reducing its environmental footprint over time. When disposed of improperly, aluminum can contribute to litter and leach harmful substances into the soil and water, affecting wildlife and potentially human health. Responsible recycling and manufacturing practices are crucial to mitigate these effects.</p>

- Q: Is it safe to use steel wires for making jewelry or decorative items, and are there any potential health hazards associated with it?

- <p>Using steel wires for jewelry or decorations generally poses minimal health risks when used properly. However, there are a few considerations: allergic reactions can occur in individuals sensitive to nickel, which is often found in stainless steel. Additionally, improper use or sharp edges can lead to cuts or injuries. It's important to ensure that the steel is of high quality and that any jewelry made is smooth and free of sharp points to minimize the risk of injury. Regular cleaning and maintenance are also recommended to prevent any potential health risks associated with bacteria buildup or skin irritation.</p>

- Q: What are the different coil handling methods for aluminum coils?

- To ensure the safe and efficient handling and storage of valuable aluminum coils, there are various methods available. Here are several options: 1. Manual Handling: This approach involves the physical lifting and movement of aluminum coils using manual labor. It necessitates proper training and the use of personal protective equipment to prevent injuries. Manual handling is suitable when dealing with smaller coils or when specialized equipment is unavailable. 2. Forklift Handling: Forklifts are commonly utilized for the handling of aluminum coils. They come equipped with specially designed coil lifters or C-hooks, which securely lift and transport the coils. Forklifts offer a more efficient and quicker method for handling larger and heavier coils. 3. Coil Lifters: Coil lifters are specialized lifting devices specifically designed for aluminum coil handling. They utilize a combination of clamps and hooks to securely grip and transport the coils. Coil lifters are often used alongside cranes or forklifts. 4. C-Hooks: C-hooks are another commonly employed method for handling aluminum coils. These hooks are attached to cranes or other lifting equipment and are designed to securely cradle the coil. C-hooks facilitate easy and controlled movement of the coil and are suitable for coils of various sizes. 5. Coil Tippers: Coil tippers are utilized to tilt the coils horizontally or vertically, making loading or unloading easier. This method reduces the risk of coil damage during handling and enhances efficiency by enabling coils to be easily placed on or removed from racks or pallets. 6. Coil Carriers: Coil carriers refer to specialized trailers or trucks specifically designed for transporting aluminum coils. They feature built-in coil cradles or beds that securely hold the coils during transportation. These carriers often have adjustable supports to accommodate different coil sizes and prevent shifting during transit. Ultimately, the choice of coil handling method depends on factors such as coil size, weight, and specific requirements. It is crucial to select the appropriate handling method to ensure worker safety, prevent coil damage, and maintain the quality of the aluminum.

- Q: Are aluminum coils suitable for heat exchanger applications?

- Yes, aluminum coils are suitable for heat exchanger applications. Aluminum has excellent thermal conductivity and corrosion resistance properties, making it an ideal choice for heat transfer in various industries such as HVAC, automotive, and refrigeration. Additionally, aluminum coils are lightweight and cost-effective, making them a popular option for heat exchangers.

Send your message to us

Copper Aluminum Coils Lennox Roller Coating Line Blue Color PE Paint Aluminum Painted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords