Laserable Continuous Casting Aluminum Circle for Kitchen Pan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

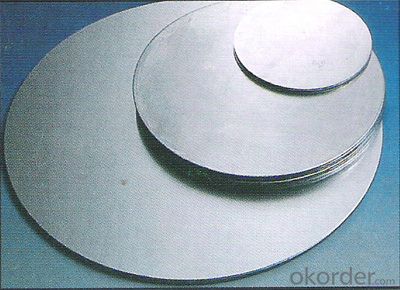

1.Structure of Continuous Casting Aluminum Circle for Kitchen Pan

Continuous Casting Aluminum Circle for Kitchen Pan is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminum Circle for Kitchen Pan

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Continuous Casting Aluminum Circle for Kitchen Pan

4. Product Specification of Direct Rolling Aluminum Coils for Second Casting

| Rolling | Temper | Thickness | Width | Weight |

| Continuous Casting | H18 | 0.2MM-3MM | 100MM-900MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the different types of edges available for aluminum sheets?

- Some of the different types of edges available for aluminum sheets include straight edges, beveled edges, hemmed edges, and rounded edges.

- Q: Can the aluminum sheets be used for soundproofing applications?

- Yes, aluminum sheets can be used for soundproofing applications. Aluminum is a lightweight and highly reflective material that can effectively block and absorb sound waves. When used in soundproofing applications, aluminum sheets can help reduce noise transmission and create a quieter environment. They can be installed as barriers, panels, or even as part of a composite material to enhance soundproofing properties. Additionally, aluminum sheets are durable, corrosion-resistant, and easy to maintain, making them suitable for long-term use in various soundproofing applications.

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Indeed, chemical storage tanks can be manufactured using aluminum sheets. Aluminum proves to be a flexible substance with numerous benefits for this particular application. Notably, its lightweight nature, resistance to corrosion, and impressive strength-to-weight ratio make it an ideal choice for securely storing a wide range of chemicals. Moreover, aluminum can be effortlessly molded into various configurations and dimensions, enabling the customization of storage tanks to suit specific needs. Nevertheless, it is crucial to take into account the type and concentration of the chemicals to be stored, as certain substances may potentially react with aluminum. In such instances, it becomes vital to employ appropriate coatings or linings to avert any chemical reactions.

- Q: What are the thermal conductivity properties of aluminum sheets?

- Aluminum sheets have high thermal conductivity properties, meaning they are excellent conductors of heat. This allows them to efficiently transfer heat and distribute it evenly across their surface.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Now, there are many kinds of ceramic curtain walls. They are made of natural clay materials. They are green, environmentally friendly, low energy consumption, and they are not easy to fade and deform. They have good corrosion resistance and durability, and high strength. At present, the domestic market of ceramic tile is faster than that of foreign countries. I heard ruigao is the first manufacturer of ceramic plate, there are other TOB ah, new Kerry ah. The strength is good.

- Q: What is the maximum temperature aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors, including the alloy composition and thickness of the sheet, as well as the specific application and environment in which it is being used. Generally, pure aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), but it begins to lose strength and stiffness at much lower temperatures. Most commercial aluminum alloys have higher melting points and can withstand higher temperatures. For example, 6061 aluminum alloy has a melting point of around 580 degrees Celsius (1076 degrees Fahrenheit), while 7075 aluminum alloy has a slightly higher melting point of around 640 degrees Celsius (1184 degrees Fahrenheit). However, it is important to note that the maximum temperature a sheet of aluminum can withstand without significant deformation or structural damage may be lower than its melting point. This is because aluminum's strength and mechanical properties degrade at elevated temperatures. In applications where aluminum sheets are subjected to high temperatures, it is crucial to consider the specific alloy and its thermal properties, as well as any potential changes in strength, hardness, or other relevant characteristics that may occur at elevated temperatures. Consulting material specifications, engineering guidelines, or seeking professional advice from metallurgical experts can provide more accurate and specific information regarding the maximum temperature capabilities of aluminum sheets for a particular application.

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q: Are 101 aluminum sheets suitable for heat sinks?

- No, 101 aluminum sheets are not suitable for heat sinks. Heat sinks are designed to dissipate heat and therefore require materials with high thermal conductivity. 101 aluminum has a lower thermal conductivity compared to other aluminum alloys commonly used for heat sinks, such as 6061 or 6063. These alloys have better thermal conductivity properties, allowing them to effectively transfer heat away from the heat source. Therefore, it is recommended to use aluminum alloys specifically designed for heat sinks to ensure optimal heat dissipation and cooling performance.

- Q: What are the different types of coatings applied to aluminum sheet?

- Aluminum sheet can be coated with various types of coatings, each possessing its own unique properties and advantages. Some commonly used coatings are as follows: 1. Anodizing: This process involves the formation of a protective layer of aluminum oxide on the sheet's surface through electrochemical means. Anodizing enhances the appearance of aluminum by creating a vibrant and long-lasting finish, while also providing excellent resistance against corrosion. 2. Powder Coating: A dry powder is applied to the aluminum sheet using electrostatic methods, and then cured under heat to form a robust and protective coating. Powder coating offers outstanding durability, chip and scratch resistance, as well as a wide range of color and finish options. 3. Paint: Aluminum sheet can be coated with paint, offering both aesthetic appeal and protection. The paint is applied as a liquid and then cured under heat to create a strong and durable coating. Paint coatings provide versatility and customization options, including a vast array of colors and finishes. 4. Laminating: To provide additional protection against scratches, abrasion, and UV damage, a thin layer of protective film or laminate is applied to the surface of the aluminum sheet. Laminating enhances the appearance of the sheet while ensuring its long-lasting durability. 5. Conversion Coatings: Chemical treatments are employed in conversion coatings to convert the surface of the aluminum sheet into a more corrosion-resistant compound. Examples of conversion coatings include chromate conversion coatings and phosphating, which create a protective layer, improving the adhesion of subsequent coatings. 6. Clear Coatings: Clear coatings, such as lacquer or clear powder coat, can be utilized to safeguard aluminum sheet against oxidation and corrosion while maintaining its natural appearance. Clear coatings are commonly used when the goal is to preserve the metallic look of the aluminum. These are just a few illustrations of the diverse range of coatings that can be applied to aluminum sheet. The selection of the appropriate coating depends on factors such as desired appearance, required level of protection, and the specific application of the aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Yes, aluminum sheets are suitable for manufacturing audio speaker enclosures. Aluminum is a lightweight and durable material that is often used in speaker enclosure construction. It offers good acoustic properties, reduces vibrations, and provides excellent heat dissipation, making it an ideal choice for speaker manufacturing.

Send your message to us

Laserable Continuous Casting Aluminum Circle for Kitchen Pan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords