Concrete Pump Truck Parts Elbow Bend DN100 R170 90DGR 127MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

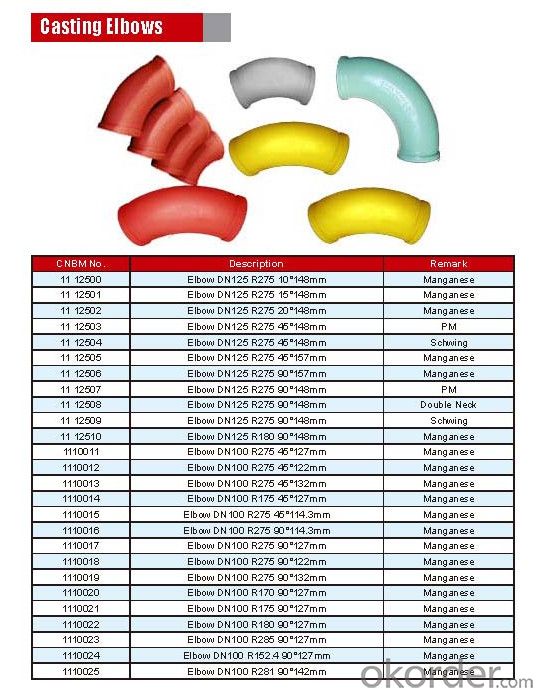

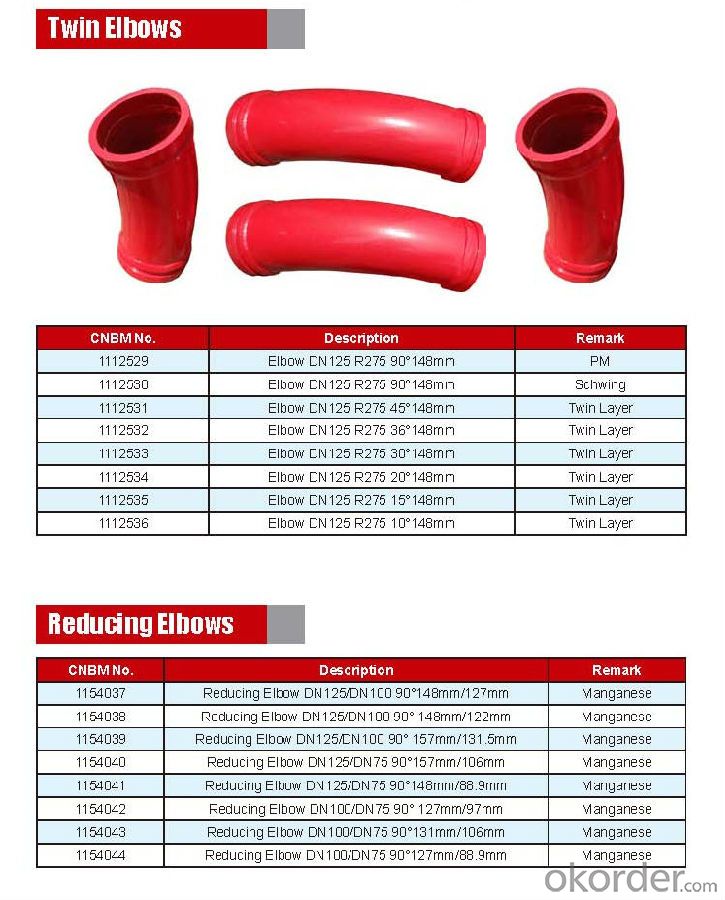

Product Specifications:

Technology: Cast

Dimension: DN100

Flange: 127mm

Radius: 170mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for more than ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: How to diagnose the blockage in the inlet of concrete pump?

- The feed port is blocked and the pump operation and hydraulic system are normal, with no abnormal sound and vibration. The hopper has larger aggregate or agglomerates and is stuck or arched at the feed port

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Yes, you can typically get spare parts for both concrete pumps with and without boom control systems. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to meet the needs of different types of pumps. Whether it's for a pump with a boom control system or one without, you should be able to find the necessary spare parts from reputable suppliers. It is recommended to contact the manufacturer or supplier directly to inquire about the availability and compatibility of spare parts for your specific concrete pump model.

- Q: How does a concrete pump piston work?

- A concrete pump piston works by creating a reciprocating motion that pushes the concrete through the pump and into the desired location. The piston is a cylindrical component that fits snugly inside a cylinder. It is connected to a rod, which is attached to a hydraulic system. When the hydraulic system is activated, it pushes the rod forward, causing the piston to move in the same direction. As the piston moves forward, it creates a vacuum behind it, drawing the concrete into the cylinder through an inlet valve. Once the piston reaches the end of its forward stroke, the hydraulic system reverses its direction, pulling the rod back and causing the piston to move backward. This closes the inlet valve and opens an outlet valve, allowing the concrete to be forced out of the cylinder and into the delivery line. The reciprocating motion of the piston, along with the alternating opening and closing of the inlet and outlet valves, allows for a continuous flow of concrete through the pump. This process is repeated rapidly, allowing for efficient and consistent pumping of concrete to the desired location.

- Q: How long does a concrete pump piston typically last?

- The lifespan of a concrete pump piston can vary depending on several factors. On average, a concrete pump piston typically lasts between 20,000 to 40,000 cubic yards of pumping. However, this estimate can be affected by a variety of factors such as the quality of the concrete being pumped, the maintenance and care of the pump, the operating conditions, and the expertise of the operator. Regular maintenance and servicing, including cleaning and lubricating the piston, can significantly extend its lifespan. It is also important to monitor the wear and tear of the piston regularly to ensure its optimal performance and to replace it when necessary.

- Q: Can I get spare parts for both concrete pumps with and without water tanks?

- Yes, you can get spare parts for both concrete pumps with and without water tanks.

- Q: How often should hopper cylinder seals be replaced in a concrete pump?

- The frequency at which hopper cylinder seals should be replaced in a concrete pump depends on several factors such as the quality of the seals, the intensity of usage, and the maintenance practices followed. Ideally, hopper cylinder seals should be inspected regularly for any signs of wear and tear or damage. If there are visible cracks, tears, or leaks, it is recommended to replace the seals as soon as possible to prevent any further damage to the concrete pump. In general, hopper cylinder seals can last anywhere from several months to a couple of years, depending on the aforementioned factors. However, it is essential to establish a preventive maintenance plan and regularly monitor the condition of the seals to ensure optimal performance and minimize downtime. Additionally, it is advisable to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for hopper cylinder seals based on the pump model, usage patterns, and environmental conditions.

- Q: How do I properly adjust and control flow rates in concrete pump spare parts?

- To properly adjust and control flow rates in concrete pump spare parts, there are a few key steps to follow: 1. Understand the equipment: Familiarize yourself with the specific concrete pump spare parts you are working with. Read the user manual and refer to any documentation provided by the manufacturer. This will help you gain a comprehensive understanding of the equipment's capabilities and how to adjust flow rates effectively. 2. Check the pump settings: Before starting any concrete pumping operation, ensure that the pump settings are properly configured. This includes checking the hydraulic pressure, engine RPM, and any other relevant settings. Make sure all valves and controls are in the correct position for the desired flow rate. 3. Monitor the pump speed: The speed of the pump directly affects the flow rate of the concrete. Different concrete mixtures may require different pump speeds to achieve the desired flow rate. Adjust the engine RPM accordingly, referring to the manufacturer's recommendations and any specific requirements for the project. 4. Adjust the pump stroke: Most concrete pumps have adjustable pump strokes to control the flow rate. By changing the length of the stroke, you can increase or decrease the volume of concrete being pumped. Experiment with different stroke lengths to find the optimal flow rate for your specific application. 5. Use the control panel: Many concrete pumps come equipped with a control panel that allows for precise adjustment of flow rates. Take advantage of these features to fine-tune the flow rate. Use the control panel to monitor the pump's performance and make any necessary adjustments to maintain a consistent flow. 6. Regularly inspect and maintain the equipment: Proper maintenance is crucial to ensure the accurate adjustment and control of flow rates. Regularly inspect the concrete pump spare parts for any signs of wear or damage. Clean and lubricate the components as recommended by the manufacturer. A well-maintained pump will operate more efficiently and provide more accurate control over flow rates. By following these steps, you can properly adjust and control flow rates in concrete pump spare parts. Remember to always prioritize safety and consult the manufacturer's instructions and guidelines for specific recommendations and considerations.

- Q: How often should agitator shaft seals be replaced in a concrete pump?

- The frequency at which agitator shaft seals should be replaced in a concrete pump depends on several factors such as the type and quality of the seal, the operational conditions of the pump, and the maintenance practices followed by the user. However, as a general guideline, it is recommended to inspect and replace agitator shaft seals in a concrete pump every 500 to 1,000 operating hours or annually, whichever comes first. Regular inspection of the seals is crucial to identify any signs of wear, leakage, or damage. If any of these issues are detected, immediate replacement is necessary to prevent further damage to the pump and ensure optimal performance. Additionally, it is essential to follow the manufacturer's recommendations and guidelines regarding seal replacements, as they may provide specific instructions based on the pump model and seal type. Proper maintenance practices, including regular cleaning and lubrication of the seals, can also extend their lifespan and reduce the need for frequent replacements. It is important to keep in mind that failure to replace worn or damaged agitator shaft seals in a timely manner can lead to increased downtime, decreased efficiency, and potential damage to other components of the concrete pump. Hence, it is crucial to prioritize regular inspection and replacement of agitator shaft seals to ensure the smooth operation and longevity of the concrete pump.

- Q: Can concrete pump spare parts be imported from other countries?

- Concrete pump spare parts can indeed be brought in from other countries. Multiple manufacturers and suppliers of these spare parts have a worldwide reach and provide options for international shipping. By importing concrete pump spare parts from other countries, one can gain access to a broader selection of products, competitive prices, and superior components. Nevertheless, it is crucial to take into account factors including import regulations, customs duties, and shipping expenses when bringing in concrete pump spare parts from other countries.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R170 90DGR 127MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords