Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Mainly adopt high wear resistant steel, and other material upon your request. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC. The elbow possesses good toughness properties, and can well protect the inside. The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3. Possess quality certification of ISO 9001:2000.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

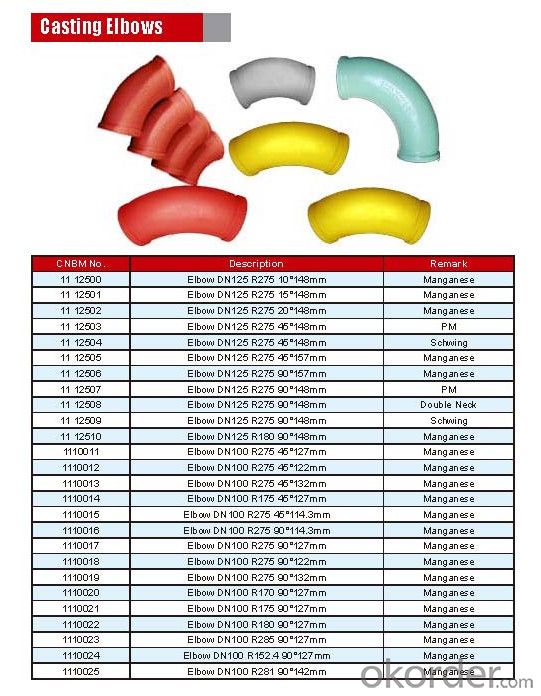

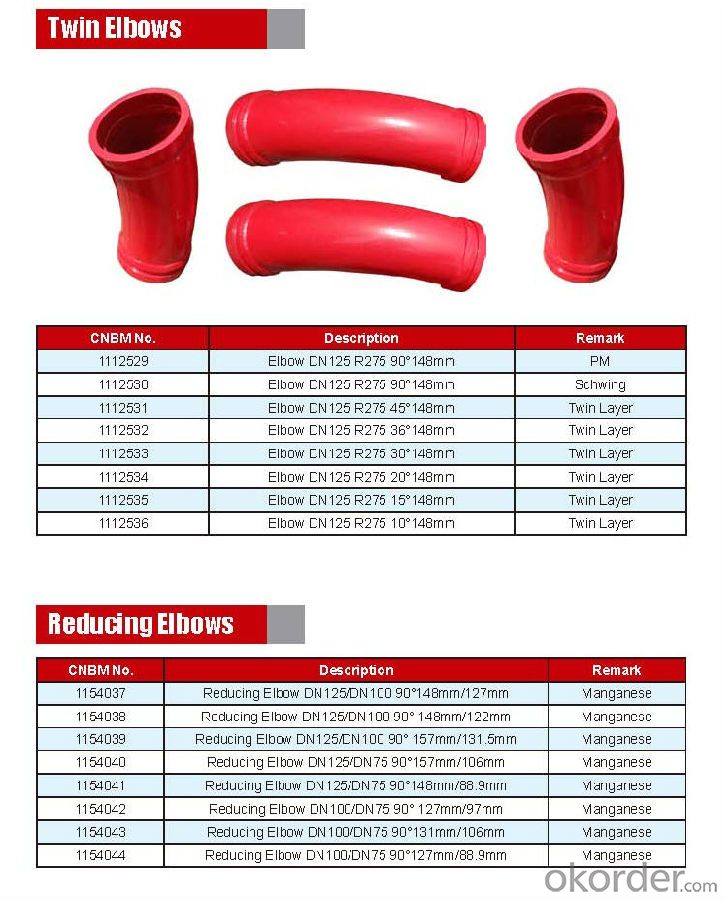

Product Specifications:

Technology: Cast

Dimension: DN100

Flange: 114.3mm

Radius: 275mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 70pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. 1. Size and Compatibility: Ensure that the hydraulic filter or strainer you are installing is the correct size and compatible with the specific make and model of the concrete pump. Using the wrong size or incompatible filter can result in poor filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that allows for proper filtration of the hydraulic fluid without obstructing the flow. 3. Mounting: The filter or strainer should be securely mounted to prevent any movement or vibration during operation. It is important to follow the manufacturer's instructions for proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and installing them incorrectly can affect their performance and efficiency. 5. Protection: Consider installing additional protection, such as a guard or shield, to prevent damage to the filter or strainer from external factors like debris or impacts. This can help prolong the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspect and clean the filter or strainer to ensure proper functioning. Follow the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain optimal filtration efficiency. It is important to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have specific recommendations or requirements unique to their product.

- Q: How can a damaged concrete pump hopper affect the pumping process?

- The pumping process can be negatively impacted by a damaged concrete pump hopper in several ways. To begin with, efficiency and productivity can decrease when the hopper is damaged. The hopper's role is to hold and feed the concrete mixture into the pump. Any damage to the hopper can disrupt the continuous flow of concrete, leading to frequent interruptions in the pumping process. This causes delays and reduces the overall output of the pump. Furthermore, the quality of the concrete being pumped can be affected by a damaged hopper. The hopper is designed to ensure proper mixing and consistency of the concrete mixture before it is pumped. If the hopper is damaged, it may not effectively mix the concrete, resulting in inconsistencies in the mixture. This can lead to poor-quality concrete being pumped, compromising the structural integrity and durability of the final product. Additionally, a damaged hopper can pose safety risks for the workers involved in the pumping process. Sharp edges or loose parts on a damaged hopper can cause injury if not addressed properly. Moreover, if the hopper is not functioning correctly, it may cause clogs or blockages in the pump, leading to pressure build-up and potential accidents. Finally, maintenance and repair costs can increase due to a damaged hopper. An imperfect hopper may require frequent repairs or even replacement, which can be time-consuming and expensive. Regular maintenance and inspection of the hopper are crucial to identify any damages early on and prevent them from escalating into more significant issues. In conclusion, a damaged concrete pump hopper has significant implications for the pumping process, including reduced efficiency, compromised concrete quality, safety risks, and increased maintenance costs. Regular inspection, maintenance, and timely repairs are essential to ensure the smooth operation of the pump and the delivery of high-quality concrete.

- Q: What are the indications of a faulty concrete pump hydraulic motor?

- Some indications of a faulty concrete pump hydraulic motor may include decreased pumping efficiency, irregular or inconsistent flow of concrete, unusual noises or vibrations, leaks or drips in the hydraulic system, excessive heat in the motor, or difficulty in starting or stopping the motor.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- Sourcing spare parts for stationary concrete pumps can present various common obstacles. Firstly, availability poses a significant challenge. Depending on the concrete pump's brand and model, locating the exact spare parts needed can prove difficult. Some manufacturers lack a widespread distribution network, making it challenging to promptly locate the required spare parts. This difficulty is intensified if the concrete pump is an older model or if the manufacturer has ceased production. Another significant challenge is cost. Spare parts for stationary concrete pumps can be pricey, particularly when sourced directly from the manufacturer. Alongside the initial cost, additional expenses like shipping, customs duties, and taxes further escalate the overall cost of acquiring spare parts. Ensuring quality assurance is a crucial aspect when sourcing spare parts. It is vital to verify that the sourced spare parts are of high quality and compatible with the specific make and model of the concrete pump. Inferior spare parts can result in performance issues, breakdowns, and potential safety hazards, detrimentally impacting the overall efficiency and lifespan of the concrete pump. Timing also plays a pivotal role in spare parts sourcing. When a concrete pump malfunctions, it can cause delays in construction projects, leading to extra expenses and potential penalties. Therefore, swiftly and efficiently finding spare parts is essential to minimize downtime and ensure smooth operations. Additionally, language and communication barriers can present challenges. If the spare parts manufacturer or supplier is situated in a different country or speaks a different language, effective communication can be problematic. This can lead to misunderstandings, delays, and difficulties in accurately conveying specific spare parts requirements. To overcome these challenges, it is advisable to collaborate with reputable suppliers specializing in concrete pump spare parts. These suppliers often maintain a vast inventory of spare parts, ensuring availability and reducing the risk of delays. Furthermore, establishing strong relationships with local distributors or authorized service centers can streamline access to spare parts and technical support. Regular maintenance and proactive planning can also help mitigate the challenges of sourcing spare parts for stationary concrete pumps. Maintaining an inventory of essential spare parts and components can minimize downtime and ensure smooth operations.

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To guarantee the compatibility of mechanical components in concrete pump spare parts, there are several essential measures you can take: 1. Determine the exact make and model of your concrete pump: Different concrete pumps may have different designs and specifications, so it is crucial to identify the specific make and model of your pump. This information will assist you in selecting the appropriate spare parts for your particular pump. 2. Review the manufacturer's documentation: Examine the manufacturer's documentation, which includes the user manual and parts catalog, to understand the recommended spare parts for your concrete pump. These documents typically provide detailed information on the compatibility of various mechanical components. 3. Seek guidance from the manufacturer or authorized dealers: If you have doubts about the compatibility of certain mechanical components, it is advisable to consult the manufacturer or authorized dealers. They possess extensive knowledge and experience with their products and can offer advice on choosing compatible spare parts. 4. Consider utilizing OEM (Original Equipment Manufacturer) parts: OEM parts are specifically designed and manufactured by the original equipment manufacturer. Employing OEM parts ensures the highest level of compatibility and reliability. Although they may be slightly more expensive than aftermarket alternatives, they often provide superior performance and longer service life. 5. Verify standardized sizing and specifications: Mechanical components, such as seals, gaskets, and bearings, frequently adhere to standardized sizes and specifications. Ensure that the spare parts you are considering match these standardized measurements to guarantee compatibility. 6. Conduct thorough research and comparison: Prior to purchasing spare parts, conduct research on various suppliers and compare their offerings. Look for reputable suppliers who specialize in concrete pump spare parts and have a proven track record of delivering high-quality, compatible components. 7. Perform compatibility testing: If you are unsure about the compatibility of a specific mechanical component, consider conducting compatibility tests. This may involve installing the spare part in your concrete pump and assessing its fit, function, and performance. If possible, seek assistance from a qualified mechanic or technician to assist you with these tests. By following these steps, you can ensure the compatibility of mechanical components in concrete pump spare parts, minimizing the risk of compatibility issues and ensuring the smooth operation and maintenance of your concrete pump.

- Q: How can one determine the correct voltage and current rating for electrical components in concrete pump spare parts?

- To determine the correct voltage and current rating for electrical components in concrete pump spare parts, several factors need to be considered. Firstly, it is essential to consult the manufacturer's specifications and documentation for the concrete pump and its spare parts. These documents usually provide detailed information about the voltage and current requirements for each electrical component. Paying close attention to these guidelines ensures that the components are operated within their designed parameters. Secondly, it is crucial to understand the electrical system and its requirements. This involves analyzing the power supply available at the site where the concrete pump will be used. Factors such as the voltage level (e.g., 110V, 220V, 440V) and frequency (e.g., 50Hz, 60Hz) of the electrical supply need to be taken into account. Additionally, the maximum current capacity of the electrical system must be considered to prevent overload situations. Furthermore, it is advisable to assess the specific application and operating conditions of the concrete pump. Different components may have varying voltage and current requirements depending on their function and the environment in which they are used. For instance, components installed in outdoor areas may require higher voltage ratings to withstand harsh weather conditions. Lastly, seeking professional assistance from qualified electricians or engineers is highly recommended. They possess the expertise and knowledge to accurately determine the voltage and current ratings for electrical components in concrete pump spare parts. Their experience allows them to consider various factors such as safety regulations, compatibility with the existing electrical system, and any specific requirements of the concrete pump manufacturer. By taking into account the manufacturer's specifications, understanding the electrical system, considering the application and operating conditions, and seeking professional advice, one can effectively determine the correct voltage and current rating for electrical components in concrete pump spare parts.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- Yes, there are several safety precautions to consider while replacing concrete pump spare parts. Firstly, it is important to wear personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. Additionally, one should ensure the pump is turned off and disconnected from the power source before attempting any repairs. It is also crucial to follow proper lifting techniques and use appropriate tools to avoid injuries. Lastly, it is advisable to have a clear understanding of the equipment and its components, and if unsure, consult with a professional or refer to the manufacturer's guidelines for safe replacement procedures.

- Q: What are the types of concrete pumps?

- The pump body and the conveying pipe are made up of. It is divided into piston type, extrusion type and water pressure diaphragm type according to the structure

- Q: How long do concrete pump spare parts typically last?

- The lifespan of concrete pump spare parts can vary depending on several factors such as usage frequency, maintenance practices, and the quality of the parts. However, on average, concrete pump spare parts are designed to last for several years before requiring replacement.

- Q: How do I ensure the reliability of concrete pump spare parts in critical applications?

- To ensure the reliability of concrete pump spare parts in critical applications, there are several steps you can take: 1. Choose a reputable supplier: Research and select a trusted supplier known for providing high-quality concrete pump spare parts. Look for suppliers with a strong track record, positive customer reviews, and certifications that demonstrate their commitment to quality and reliability. 2. Verify product specifications and certifications: Before purchasing any spare parts, carefully review the product specifications and certifications. Ensure that the parts meet the required standards and have undergone rigorous testing to guarantee their reliability in critical applications. 3. Conduct regular maintenance and inspections: Implement a comprehensive maintenance and inspection schedule for your concrete pump and its spare parts. Regularly check for signs of wear, damage, or malfunction. Replace any parts that show signs of deterioration or that no longer meet the required specifications. 4. Use genuine spare parts: Always opt for genuine spare parts that are specifically designed for your concrete pump model. Genuine parts are manufactured to the highest standards and are more likely to provide reliable performance in critical applications compared to generic or counterfeit alternatives. 5. Keep an inventory of critical spare parts: Identify the most critical spare parts that are prone to failure or wear and keep an inventory of these parts on hand. This will minimize downtime in case of unexpected failures and ensure that you can quickly replace any faulty components. 6. Train and educate operators: Provide thorough training to your concrete pump operators on proper handling and maintenance of spare parts. Educate them on the importance of following manufacturer guidelines and best practices to maximize the reliability and longevity of the equipment. 7. Prioritize safety: Safety should always be a top priority in critical applications. Ensure that the spare parts you use are compliant with safety regulations and standards. Regularly assess and update safety protocols to minimize the risk of accidents or equipment failure. By following these steps, you can enhance the reliability of concrete pump spare parts in critical applications, reducing the likelihood of downtime and ensuring the smooth operation of your equipment.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords