Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life: 55000-150000 CBM Concrete. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

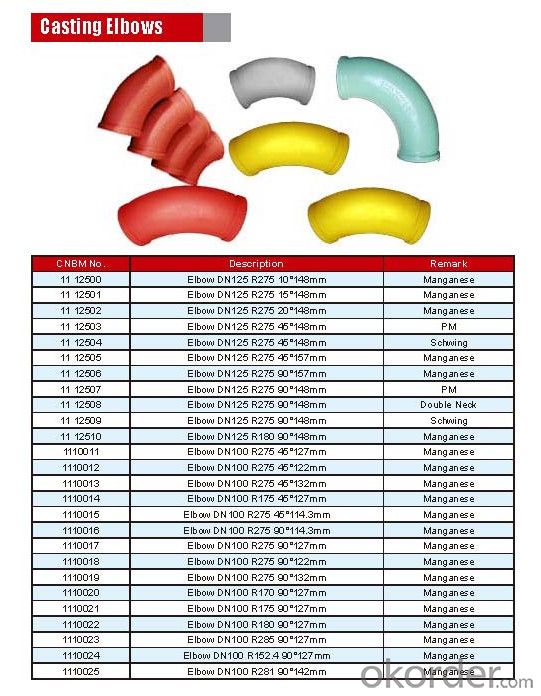

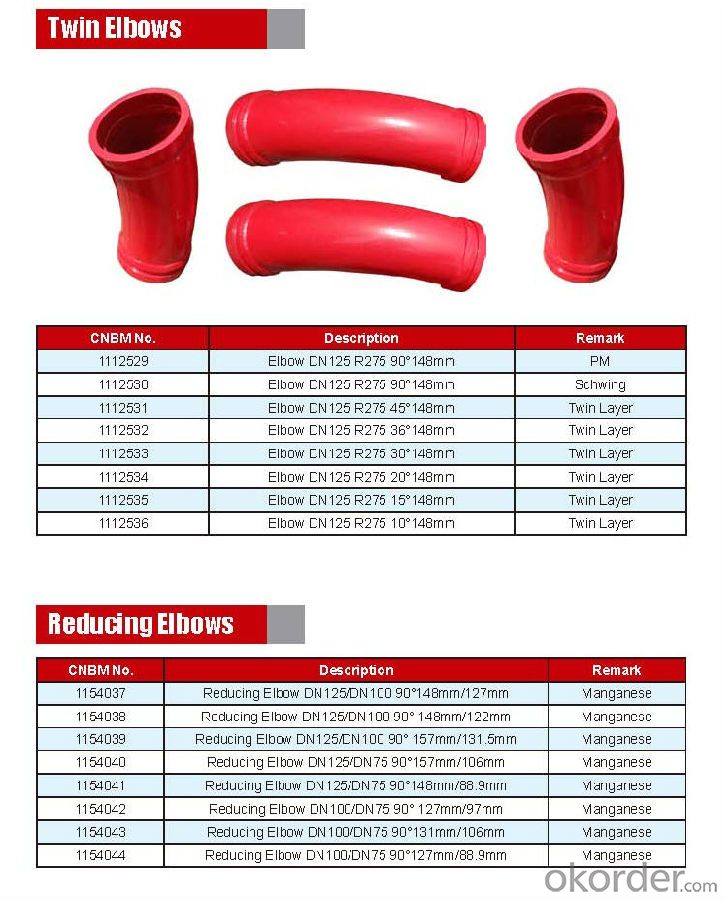

Product Specifications:

Technology: Cast

Dimension: DN100

Radius: 275mm

Degree: 45D

Material: Mn13-4

Weight: 6kg

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 140pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What are the indicators of a faulty concrete pump seal?

- There are multiple signs that may suggest a defective concrete pump seal. These signs include: 1. Leakage: One of the most evident indications of a faulty seal is when concrete or water leaks around the seal area. If you observe any fluid seeping out from the seal, it is a clear sign of a problem. 2. Decreased pumping efficiency: A faulty seal can lead to reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: The operation of a concrete pump may experience heightened noise and vibration due to a defective seal. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be necessary. 4. Premature wearing and tearing: A defective seal can cause premature wear and tear on other components within the pump system. This can be observed through the deterioration of other parts like gaskets, bearings, or pistons. Regular inspections can help identify such problems. 5. Inconsistent pressure: A faulty seal may result in inconsistent pressure while pumping concrete. If you notice pressure variations or irregular concrete flow, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a defective seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. Addressing any sign of a defective concrete pump seal promptly is crucial to prevent further damage to the pump system and ensure the operation's safety and efficiency. It is recommended to seek guidance and repair from a professional or contact the manufacturer in such cases.

- Q: What is the difference between concrete pump and ground pump?

- The pump is easy to move and flexible, but generally limited to the length of the boom by 60-70m. The ground pump is not limited by height, but it needs to be connected with the conveying pipe, which is of poor flexibility

- Q: How can a faulty gearbox affect the pump's performance?

- A faulty gearbox can negatively affect the pump's performance by causing issues such as uneven rotation, decreased efficiency, increased noise, and possible breakdowns.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- To minimize downtime during the replacement of concrete pump spare parts, it is crucial to follow a few key steps. First, ensure that you have a comprehensive understanding of the specific spare parts required for your concrete pump. This will help you streamline the ordering process and minimize delays. Additionally, it is essential to schedule regular maintenance and inspections to identify any potential issues beforehand, allowing you to proactively replace parts before they fail. Lastly, work with a reputable supplier who can provide high-quality spare parts promptly, reducing downtime.

- Q: What is the washing process of the concrete pump pipe?

- Anti pump action a few times, release the pipe pressure, cut off the power supply

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: How to calculate the power of concrete pump motor?

- Of course, the motor power is large, the transmission speed is fast

- Q: Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control panels or electronic components in concrete pump spare parts. When installing control panels or electronic components in concrete pump spare parts, it is important to consider the following guidelines: 1. Protection from Moisture: Concrete pump spare parts are exposed to moisture, which can be detrimental to electronic components. It is advisable to install control panels or electronic components in waterproof or moisture-resistant enclosures to prevent damage from water or humidity. 2. Vibration and Shock Absorption: Concrete pump spare parts are subject to vibration and shock during operation. To prevent damage to control panels or electronic components, it is recommended to use shock-absorbing mounts or vibration-resistant enclosures to minimize the impact of these forces. 3. Temperature Control: Concrete pump spare parts can be exposed to extreme temperatures, both hot and cold. It is crucial to ensure that control panels or electronic components are installed in a temperature-controlled environment. This may involve using insulation or cooling systems to maintain a suitable operating temperature range. 4. Wiring and Connections: Proper wiring and connections are essential for the functioning of control panels or electronic components. It is important to follow the manufacturer's instructions and guidelines for wiring, ensuring that connections are made securely and that proper insulation and protection are provided to prevent short circuits or electrical hazards. 5. Accessibility and Maintenance: Control panels or electronic components should be installed in a manner that allows easy accessibility for maintenance and repairs. It is recommended to leave enough space around the components for easy inspection, servicing, and replacement if necessary. By adhering to these guidelines, the installation of control panels or electronic components in concrete pump spare parts can be done in a manner that ensures their long-term functionality and durability.

- Q: What is the purpose of a concrete pump accumulator?

- The purpose of a concrete pump accumulator is to store hydraulic energy and provide a surge of pressure when needed, ensuring a continuous and efficient flow of concrete during pumping operations.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- Yes, there are several safety precautions to consider while replacing concrete pump spare parts. Firstly, it is important to wear personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. Additionally, one should ensure the pump is turned off and disconnected from the power source before attempting any repairs. It is also crucial to follow proper lifting techniques and use appropriate tools to avoid injuries. Lastly, it is advisable to have a clear understanding of the equipment and its components, and if unsure, consult with a professional or refer to the manufacturer's guidelines for safe replacement procedures.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords