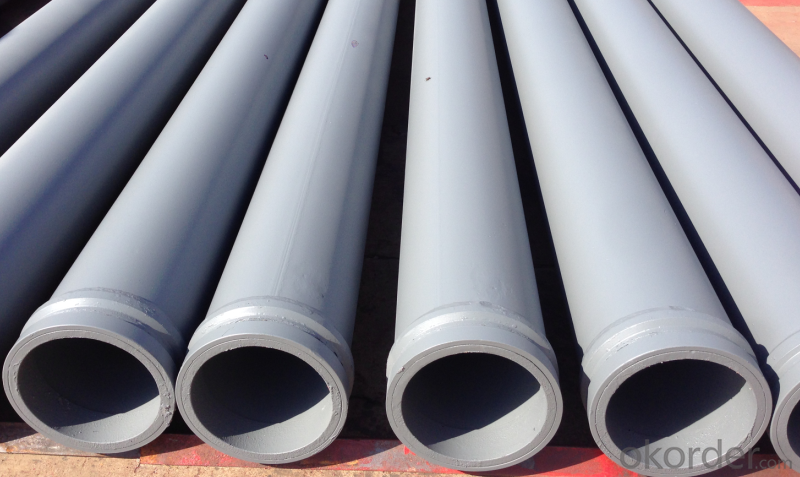

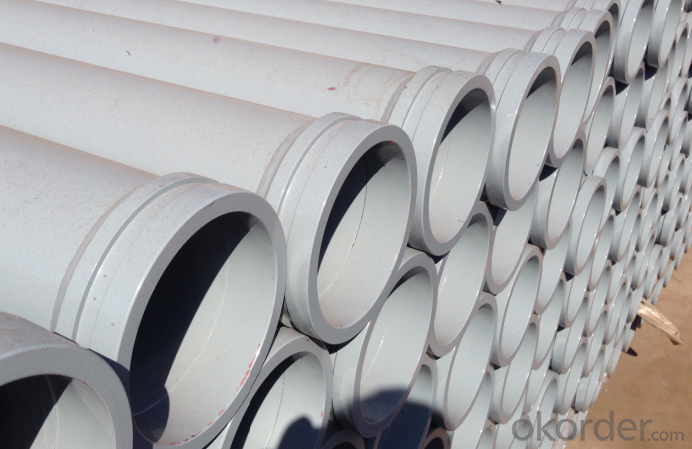

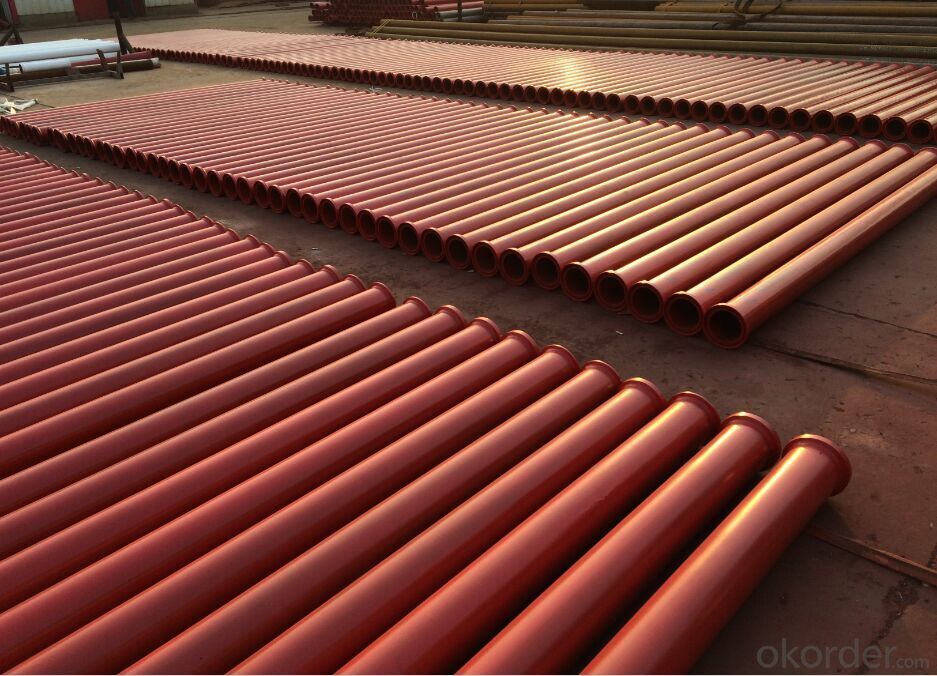

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 2MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Uniform baking finish.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 2m

Thickness: 3.2mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: How can a faulty filter affect the pumping process?

- A faulty filter can impede the pumping process by allowing debris, contaminants, or particles to pass through and clog or damage the pump components. This can result in reduced efficiency, increased wear and tear, decreased flow rates, and potential pump failure.

- Q: How often should a concrete pump cleaning ball be used?

- A concrete pump cleaning ball should be used after every use of the pump to ensure proper maintenance and prevent clogs or blockages.

- Q: How does a hydraulic accumulator improve the performance of a concrete pump?

- A hydraulic accumulator improves the performance of a concrete pump by ensuring a constant and reliable flow of concrete. The primary function of a hydraulic accumulator is to store hydraulic energy in the form of fluid under pressure. In the case of a concrete pump, this accumulator stores energy from the hydraulic system and releases it when needed to assist in the pumping process. Concrete pumps require a consistent flow of concrete to maintain efficiency and productivity. However, the process of pumping concrete can be challenging, especially when dealing with variations in demand or pressure fluctuations. This is where a hydraulic accumulator comes into play. By storing excess hydraulic energy, the accumulator acts as a buffer, smoothing out any inconsistencies in the hydraulic system. When the pump requires an extra surge of power, the accumulator releases the stored energy, providing an additional boost to the hydraulic system. This ensures a continuous and steady flow of concrete, even during peak demand or pressure changes. Moreover, hydraulic accumulators also help in reducing the wear and tear on the pump components. By absorbing and dampening pressure shocks, they prevent sudden pressure spikes and fluctuations from reaching the pump. This helps to prolong the lifespan of the pump and minimize the risk of breakdowns or damage. Overall, a hydraulic accumulator plays a crucial role in improving the performance of a concrete pump by providing a steady flow of concrete, reducing pressure fluctuations, and protecting the pump from excessive wear and tear. It enhances the efficiency, reliability, and durability of the pump, ultimately leading to increased productivity and cost savings in concrete pumping operations.

- Q: Can I get spare parts for both concrete pumps with and without agitators?

- Spare parts for both types of concrete pumps, whether they have agitators or not, are readily available. Numerous manufacturers and suppliers offer an extensive selection of spare parts to guarantee the efficient functioning and upkeep of these machines. Wear plates, cutting rings, delivery cylinders, pistons, seals, hoses, valves, and filters are among the many spare parts provided. To determine the availability and cost of spare parts for both types of pumps, it is advisable to reach out to the manufacturer or authorized dealers of the concrete pump brand you are utilizing.

- Q: What is the concrete delivery pump?

- Currently mainly divided into gate valve, concrete pump and S valve concrete pump

- Q: What is the farthest pumping distance of concrete pump truck?

- Now the domestic pump to achieve the highest pump height, the largest is ZOOMLION made 80 m carbon fiber boom pump, but also to achieve the pump Guinness world record

- Q: What is the role of a concrete pump hopper agitator blade?

- The concrete pump hopper agitator blade is responsible for maintaining the consistency and flow of the concrete while it is being pumped. Its purpose is to mix the concrete in the hopper, preventing it from settling or becoming too thick. By continuously stirring the concrete, the agitator blade ensures that it maintains the correct consistency, making it easier to pump and ensuring a more even distribution of the material. This is especially important when working with large amounts of concrete or pumping over long distances, as it helps to prevent blockages and maintain a smooth and efficient pumping process. In summary, the agitator blade is essential for the successful operation of a concrete pump, ensuring that the concrete remains in a workable condition throughout the pumping process.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Yes, it is possible to get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve. Concrete pump manufacturers and suppliers usually offer a wide range of spare parts for their equipment, including valves. These spare parts can be ordered directly from the manufacturer or through authorized distributors. It is important to provide specific information about the concrete pump model, valve type, and any other relevant details when ordering spare parts to ensure compatibility. Additionally, there are specialized companies that focus on supplying spare parts for concrete pumps, regardless of the valve system type. These companies often have a comprehensive inventory of spare parts and can assist in identifying and sourcing the required parts for your specific concrete pump.

- Q: How often should hydraulic pumps be inspected or replaced in a concrete pump?

- Regular inspections of hydraulic pumps in a concrete pump are essential for maintaining their proper functioning and preventing potential problems. The frequency of these inspections depends on various factors, such as the intensity of use, operating conditions, and manufacturer's guidelines. Typically, it is advisable to inspect hydraulic pumps in a concrete pump either every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, if the pump is being used under harsh or demanding circumstances, more frequent inspections might be required. The decision to replace hydraulic pumps should be based on their condition and the recommendations provided by the manufacturer. If the pump displays significant wear and tear, leaks, reduced performance, or any other issues that cannot be resolved through maintenance or repair, it may be necessary to replace the hydraulic pump to ensure the safe and efficient operation of the concrete pump.

- Q: Are there any specific quality control measures for the production of concrete pump spare parts?

- Yes, there are specific quality control measures for the production of concrete pump spare parts. These measures are put in place to ensure that the spare parts meet the required specifications and are of high quality. One of the key quality control measures is the use of standardized production processes. Manufacturers follow specific procedures and guidelines to produce the spare parts, ensuring consistency and accuracy in the manufacturing process. This includes using quality materials, following precise measurements, and employing advanced manufacturing techniques. Quality control also involves rigorous testing and inspection of the spare parts throughout the production process. This includes conducting dimensional checks, hardness tests, and material composition analysis, among others. These tests help identify any defects or deviations from the required standards, allowing for timely corrective actions. Additionally, manufacturers may implement quality management systems, such as ISO 9001, to ensure continuous improvement in their production processes. These systems help establish quality objectives, monitor performance, and implement corrective actions when necessary. Furthermore, manufacturers may engage in third-party quality assessment and certification programs. This involves independent organizations conducting audits and inspections to ensure that the spare parts meet the required quality standards. Certifications from these programs provide assurance to customers about the quality and reliability of the spare parts. Overall, the production of concrete pump spare parts undergoes stringent quality control measures to ensure that they meet the necessary specifications and are of high quality. These measures help maintain the performance and durability of the spare parts, ensuring their reliability in concrete pump applications.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 2MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords