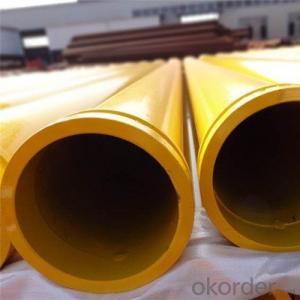

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Adopt ST52 as standard material, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life:7000-80000 CBM Concrete.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 3m

Thickness: 3.2mm

Material: ST52

Characteristics: two-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines are important to ensure the proper functioning and accurate readings of the sensors or transmitters. Firstly, it is crucial to carefully select the location for installing the sensors or transmitters. The chosen location should allow for easy access and maintenance, while also ensuring that the sensors or transmitters are not exposed to excessive vibration, moisture, or extreme temperatures. Secondly, it is recommended to use appropriate mounting hardware for securing the sensors or transmitters to the concrete pump spare parts. This hardware should be able to withstand the operating conditions and any potential vibrations or shocks that may occur during the pumping process. Additionally, it is important to follow the manufacturer's instructions for wiring and connection of the sensors or transmitters. Proper wiring and connection are essential to ensure accurate and reliable data transmission. Furthermore, regular inspections and maintenance should be conducted to ensure that the sensors or transmitters are functioning correctly. This includes checking for any loose connections, signs of wear or damage, and ensuring that the sensors or transmitters are calibrated properly. Overall, following these specific guidelines for the installation of sensors or transmitters in concrete pump spare parts can help to ensure their optimal performance and longevity, ultimately enhancing the efficiency and safety of the concrete pumping operation.

- Q: How often should hopper screens be cleaned or replaced?

- It is important to clean or replace hopper screens regularly, usually every 3 to 6 months, depending on how often they are used and the type of materials being processed. Keeping the hopper screens clean is crucial for maintaining peak performance and preventing clogs or obstructions. If the screens become excessively dirty or damaged, they should be replaced immediately to avoid interruptions in material flow and potential equipment damage. Regularly maintaining and inspecting the hopper screens will help extend their lifespan and ensure the entire system operates smoothly.

- Q: How do I identify the right spare part for my concrete pump model?

- If you want to find the correct spare part for your concrete pump model, there are several steps you can take: 1. Begin by referring to the manufacturer's manual. This manual is a great starting point because it typically contains detailed information about your concrete pump model and the corresponding spare parts. Look for part numbers, descriptions, and any specific instructions regarding ordering or replacing parts. 2. Conduct online research. Utilize the internet to search for your specific concrete pump model and related spare parts. Many manufacturers have official websites or authorized distributors that provide product catalogs or online databases where you can search for the exact part you need. Look for compatibility charts or diagrams that match your concrete pump model with the appropriate spare parts. 3. Seek advice from a specialist. If you are uncertain about the compatibility or availability of spare parts for your concrete pump model, it is advisable to consult with a specialist. Reach out to the manufacturer's customer service or contact a local distributor or service center that specializes in concrete pumps. Provide them with details about your pump model and the specific part you require, and they should be able to assist you in identifying the correct spare part. 4. Speak with other concrete pump owners. Get in touch with other owners or operators of concrete pumps who have the same or a similar model as yours. They may have experience with finding and replacing spare parts and can offer recommendations or tips on where to search or who to contact. Remember, it is vital to ensure that the spare part you select is compatible with your concrete pump model to prevent any damage or malfunctions. Taking the time to conduct research and seek advice from experts will help you find the appropriate spare part and keep your concrete pump operating smoothly.

- Q: How do I properly maintain and replace hydraulic valves in concrete pump spare parts?

- To ensure the smooth operation and long life of your concrete pump spare parts, it is crucial to properly maintain and replace the hydraulic valves. Here are some guidelines to follow: 1. Conduct Regular Inspections: Regularly inspect the hydraulic valves for wear, damage, or leaks. Look for visible defects like cracks, corrosion, or other signs of deterioration. It is important to identify and address any issues early on to prevent further damage. 2. Maintain Cleanliness: Keep the hydraulic valves clean to prevent dirt, debris, or contaminants from entering the system. Use an appropriate cleaning agent and a lint-free cloth to wipe the valves and remove any buildup. 3. Ensure Proper Lubrication: Proper lubrication is vital for the smooth functioning of hydraulic valves. Consult the manufacturer's guidelines to determine the suitable lubricant and the recommended lubrication schedule. Apply the lubricant as instructed. 4. Promptly Replace Damaged Valves: If a hydraulic valve is beyond repair or excessively worn out, it is crucial to replace it promptly. Consult the equipment's manual or seek guidance from the manufacturer to identify the correct replacement valve. Make sure the replacement valve matches the required specifications for your concrete pump. 5. Seek Professional Assistance: While operators can handle some maintenance tasks, it is advisable to seek professional assistance for complex maintenance and replacement procedures. Professional technicians possess the expertise and knowledge to handle hydraulic valves safely and effectively. 6. Prioritize Safety: Always adhere to proper safety protocols when working with hydraulic valves. Release all pressure and fully depressurize the system before attempting any maintenance or replacement. Wear appropriate personal protective equipment, such as gloves and safety goggles, to safeguard yourself from potential hazards. In conclusion, regular maintenance, timely replacement, and adherence to safety guidelines are crucial for maintaining and replacing hydraulic valves in concrete pump spare parts. By following these steps, you can ensure the reliable and efficient operation of your equipment.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning and prevent any potential issues. However, the frequency of inspections may vary depending on the specific conditions of use and the manufacturer's recommendations. During these inspections, it is essential to check for any signs of wear, damage, or corrosion on the hopper grate pin retainers. If any of these issues are detected, immediate replacement is necessary to maintain the efficiency and safety of the concrete pump. Additionally, it is crucial to adhere to the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may recommend replacing them after a certain number of operating hours, while others may suggest replacement based on the visual condition during inspections. Regular inspections and timely replacement of hopper grate pin retainers are crucial to prevent potential malfunctions or accidents during concrete pumping operations. It is always recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines regarding the inspection and replacement intervals for hopper grate pin retainers.

- Q: How often should concrete pump lubrication systems be inspected and maintained?

- Concrete pump lubrication systems should be inspected and maintained regularly to ensure their proper functioning and longevity. The frequency of inspections and maintenance will depend on various factors such as the type of pump, its usage, and the manufacturer's recommendations. Generally, it is recommended to inspect and maintain concrete pump lubrication systems on a monthly basis. This allows for early detection of any potential issues or wear and tear that may require attention. Additionally, regular inspections can help identify any signs of lubricant degradation or contamination, which can impact the efficiency and performance of the system. During the inspection, it is important to check for any leaks, damaged or worn-out components, and ensure that all lubrication points are properly greased. The lubrication system should also be cleaned to remove any debris or contaminants that may have accumulated over time. In addition to monthly inspections, certain maintenance tasks should be performed at regular intervals. This may include changing the lubricant and filters, adjusting or replacing belts and hoses, and checking the system for proper pressure and flow. It is important to note that the manufacturer's guidelines and recommendations should always be followed when it comes to inspecting and maintaining concrete pump lubrication systems. They may provide specific instructions based on the type and model of the pump, as well as any unique requirements. By regularly inspecting and maintaining concrete pump lubrication systems, you can ensure their optimal performance, minimize downtime, and extend their lifespan.

- Q: What is the first generation pumping technology of concrete pump?

- The failure rate and maintenance cost are very high, and it is easy to delay the progress of the project

- Q: How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary depending on several factors such as the brand, type of part, and the supplier. On average, concrete pump spare parts can range from a few hundred dollars to several thousand dollars. Common spare parts such as pistons, seals, and wear plates tend to have lower price points, while more complex components like hydraulic cylinders or control boards can be more expensive. Additionally, the quality and durability of the spare part can also affect the price. It is advisable to compare prices from different suppliers and consider factors like warranty and customer reviews before making a purchase.

- Q: What is the purpose of a concrete pump cylinder?

- The purpose of a concrete pump cylinder is to provide the necessary pressure and force to transport and deliver concrete from the pump to the desired location. The cylinder is an essential component of a concrete pump, as it allows for the efficient movement of concrete through the pump system. The cylinder works by using hydraulic pressure to push the concrete through the pipeline, ensuring a continuous and smooth flow of concrete. It plays a crucial role in construction projects, enabling concrete to be precisely and efficiently placed in various locations, such as buildings, bridges, or other structures. By providing the necessary power and pressure, the concrete pump cylinder ensures that concrete can be transported over long distances, vertically or horizontally, with minimal effort and labor. Overall, its purpose is to facilitate the efficient and precise delivery of concrete, saving time and effort in construction projects.

- Q: What is the function of a concrete pump remote control antenna?

- The primary role of a concrete pump remote control antenna is to establish a wireless connection between the remote control device and the concrete pump. This connection enables the operator to remotely manage various functions of the concrete pump, including initiating and terminating the pump, adjusting concrete speed and flow, and controlling boom movements. The antenna receives signals transmitted by the remote control device and transmits them to the concrete pump, enabling the operator to safely control the pump from a distance. By providing the operator with improved visibility of the pump and its surroundings, while maintaining complete operational control, this technology contributes to enhanced efficiency, accuracy, and safety at construction sites.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords