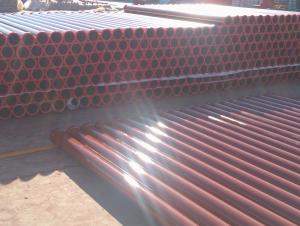

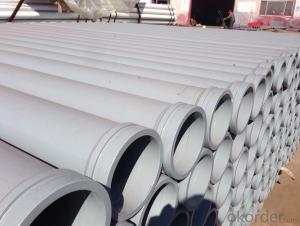

CONCRETE PUMP DELIVERY PIPE WITH 175 Male and female Fange

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification of Concrete Delivery Pipe

Materials: ST52

Concrete Pumping Capacity: about25, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 5.0mm

Length: 3000mm

2. Application of Concrete Delivery Pipe

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc.

Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc. Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concretepump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston,

tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump

parts and accessory business.

3. Package and Delivery of Concrete Pump Elbow

Every 260pcs put in one 20feet container.

4. FAQ

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some CONCRETE PUMP DELIVERY PIPE WITH 175 Male and female Fange according to customers request?

A4: Yes, we can produce CONCRETE PUMP DELIVERY PIPE WITH 175 Male and female Fange according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Yes, concrete pump spare parts can be pre-assembled or pre-tested before installation. Pre-assembling the spare parts allows for quality control measures to be taken before the actual installation process. This ensures that any defects or issues with the parts can be identified and rectified before they are installed in the concrete pump. Additionally, pre-testing the spare parts helps to ensure their functionality and compatibility with the pump system. It allows for any necessary adjustments or modifications to be made beforehand, reducing the risk of complications during the actual installation process. Overall, pre-assembling and pre-testing concrete pump spare parts is a common practice to ensure the smooth and efficient operation of the pump system.

- Q: How often should concrete pump control boxes be inspected and replaced?

- Concrete pump control boxes should be inspected regularly to ensure proper functioning and safety. The frequency of inspections and replacements will depend on various factors including the usage of the concrete pump, the operating conditions, and the manufacturer's recommendations. In general, it is advisable to inspect the control box at least once a year or as per the manufacturer's guidelines. However, if the concrete pump is used extensively or subjected to harsh operating conditions, more frequent inspections may be necessary. This includes inspecting the electrical connections, switches, buttons, and indicators for any signs of wear, damage, or malfunction. Additionally, it is important to conduct inspections after any significant maintenance or repair work on the concrete pump, as well as after any incidents or accidents. Regular inspections help identify any potential issues early on, allowing for timely repairs or replacements, thereby minimizing the risk of breakdowns or accidents. As for replacements, control boxes should be replaced if they are damaged beyond repair or if they are outdated and no longer meet safety standards. It is important to consult the manufacturer or a qualified professional to determine the appropriate replacement schedule based on the specific conditions and usage of the concrete pump. Remember, regular inspections and timely replacements of concrete pump control boxes are crucial to ensure the safe and efficient operation of the equipment.

- Q: What is the concrete delivery pump?

- The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q: Can concrete pump spare parts be repaired or refurbished?

- Yes, concrete pump spare parts can be repaired or refurbished if they are damaged or worn out. This can help extend their lifespan and save costs compared to purchasing new parts.

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Typically, individual replacement of concrete pump spare parts is possible, eliminating the need to replace the entire set. This advantageous approach enables economical maintenance and repair of the pump. By solely replacing the faulty or worn-out part, operators can ensure the pump's optimal functionality without incurring unnecessary expenses. Furthermore, individual part replacement offers enhanced flexibility and customization since different components wear out at varied rates based on their usage. However, it is worth noting that some manufacturers may recommend replacing certain parts as a set or in specific combinations to achieve optimal performance. Consequently, it is always advisable to consult the manufacturer's guidelines or seek professional advice when replacing spare parts for concrete pumps.

- Q: How often should hydraulic filters be replaced in a concrete pump?

- Hydraulic filters in a concrete pump should be replaced on a regular basis to ensure optimal performance and longevity of the equipment. The exact frequency of replacement will depend on various factors such as the specific model of the concrete pump, the operating conditions, and the quality of hydraulic fluid used. As a general guideline, it is recommended to replace hydraulic filters in a concrete pump every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, it is essential to refer to the manufacturer's recommendations and guidelines for the specific model of the concrete pump, as they may have specific maintenance schedules and intervals. Regular inspection of the hydraulic filters is also crucial to determine if replacement is necessary sooner than the recommended interval. If the filters are clogged, damaged, or show signs of excessive wear, they should be replaced immediately to prevent any potential damage to the hydraulic system. Additionally, if the concrete pump is operating in harsh or dusty environments, the filters may need to be replaced more frequently to ensure proper filtration and prevent contamination. Overall, proper and timely replacement of hydraulic filters in a concrete pump is essential to maintain the efficiency and reliability of the equipment, prevent potential breakdowns, and extend its service life.

- Q: What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q: How can one determine the correct weight and balance requirements for concrete pump spare parts?

- To determine the correct weight and balance requirements for concrete pump spare parts, one should refer to the manufacturer's specifications and guidelines. These documents usually provide information on the recommended weight limits and distribution for each spare part. Additionally, consulting with industry professionals or engineers with expertise in concrete pump systems can help ensure accurate weight and balance calculations.

- Q: Can a concrete pump pipe be repaired or should it be replaced?

- A concrete pump pipe can typically be repaired rather than replaced, depending on the extent of the damage.

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- There are several indications that can suggest an inaccurate concrete pump pressure gauge. Here are a few: 1. Inconsistent readings: If the pressure gauge consistently gives varying readings even when the concrete pumping conditions remain constant, it could be a sign of an inaccurate gauge. For example, if the gauge displays a pressure of 1000 psi one moment and then jumps to 1500 psi without any significant changes in the pumping operation, it could indicate an issue with the gauge. 2. Unusual or abnormal readings: If the pressure gauge consistently displays extremely high or low pressure readings that are significantly different from the expected values, it could signify an inaccurate gauge. It is important to be aware of the typical pressure range for the specific concrete pumping operation to identify abnormal readings. 3. Incongruity with other gauges: If there are multiple pressure gauges installed in the concrete pumping system, and they provide significantly different readings, it could suggest that one or more of the gauges are inaccurate. Comparing the readings of various gauges can help determine if a particular gauge is faulty. 4. Inadequate pump performance: If the concrete pump is not performing as expected, such as experiencing reduced output or inconsistent flow rates, it could be due to inaccurate pressure readings. Inaccurate pressure measurements can affect the control of the pump's hydraulic system, leading to inefficiencies in pumping operations. 5. Physical damage or wear: Any visible damage or signs of wear on the pressure gauge, such as cracked glass, bent needles, or loose connections, can compromise its accuracy. Such physical damage can lead to inaccurate readings and should be addressed promptly. It is important to regularly calibrate and maintain the pressure gauge to ensure accurate readings. If any indications of an inaccurate gauge are observed, it is recommended to consult a professional technician or engineer to assess the situation and take appropriate actions to rectify the issue.

Send your message to us

CONCRETE PUMP DELIVERY PIPE WITH 175 Male and female Fange

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords