CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

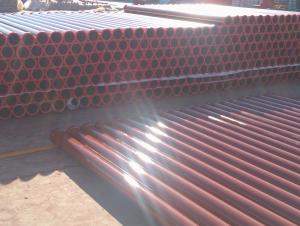

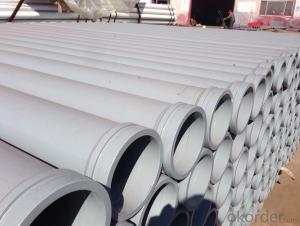

Product Name:CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

Materials: ST 52

Concrete Pumping Capacity: about 20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available.

Scope of Application of the Equipment

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE according to customers request?

A4: Yes, we can produce CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How do I properly maintain and replace hydraulic hoses in concrete pump spare parts?

- To ensure the smooth functioning and longevity of your equipment, it is crucial to properly maintain and replace hydraulic hoses in concrete pump spare parts. Here are some effective steps you can take: 1. Conduct regular visual inspections to identify any signs of wear, damage, or leaks. Look for bulges, cracks, abrasions, or fraying. Pay attention to fittings, connections, and bends in the hose. 2. Implement a preventive maintenance schedule to reduce the chances of unexpected hose failure. Clean the hoses regularly to remove dirt, debris, and concrete residues that may cause abrasion or clogging. Use a mild detergent and water, and ensure thorough drying. 3. Store hydraulic hoses in a clean, dry, and temperature-controlled environment when not in use. Protect them from direct sunlight, extreme temperatures, and chemicals to avoid degradation. 4. Handle hydraulic hoses with care to prevent damage. Avoid dragging them on rough surfaces or sharp edges that can cause cuts or abrasions. Minimize excessive kinking or twisting, as it weakens the internal structure. 5. Replace hydraulic hoses promptly upon noticing signs of wear, damage, or leaks. Do not wait for hose failure, as it can lead to costly downtime and safety hazards. Follow the manufacturer's recommendations for replacement intervals. 6. Use high-quality replacement hoses that are compatible with your concrete pump. Choose hoses that meet industry standards and specifications for durability in concrete pumping conditions. 7. Properly install replacement hoses, ensuring correct routing and secure connections to fittings. Use appropriate tools and techniques to tighten fittings, avoiding over-tightening that can damage the hose or fittings. 8. Provide regular training to your staff on proper maintenance, inspection, and replacement procedures for hydraulic hoses. This will enhance their knowledge and skills, reducing the risks of improper handling or installation. By following these steps, you can effectively maintain and replace hydraulic hoses in concrete pump spare parts, ensuring the safety and efficiency of your equipment. Always refer to the manufacturer's guidelines and seek professional assistance when needed.

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts. These guidelines typically include ensuring proper alignment and fit, using the correct torque specifications for fasteners, and applying appropriate lubrication. It is important to follow these guidelines to ensure optimal performance and longevity of the wear parts.

- Q: How often should a concrete pump cleaning ball be used?

- A concrete pump cleaning ball should be used after every use of the pump to ensure proper maintenance and prevent clogs or blockages.

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- Hopper agitator shaft seals in a concrete pump should be replaced as per the manufacturer's recommendations. However, as a general guideline, it is advisable to inspect and replace them annually or whenever signs of wear, leakage, or reduced performance are observed. Regular maintenance and proper lubrication can also help prolong the lifespan of these seals.

- Q: Can concrete pump spare parts be used interchangeably between different pump brands or models?

- No, concrete pump spare parts cannot be used interchangeably between different pump brands or models. Each pump brand and model is designed with specific specifications and dimensions, so the spare parts need to be specifically manufactured to fit those requirements. Attempting to use spare parts from a different brand or model may result in compatibility issues or even damage to the pump. It is always recommended to use genuine spare parts from the same brand or model to ensure proper functioning and longevity of the pump.

- Q: What is the role of a concrete pump spectacle plate?

- The main purpose of a concrete pump spectacle plate is to provide a stable and secure platform for the concrete pump to rest on while it is in operation. It serves as a support base for the pump, ensuring that it remains steady and balanced while it pumps concrete. The spectacle plate is typically constructed using durable materials like steel or alloy, which can withstand the weight and pressure exerted by the pump. Its design incorporates various features, such as slots or holes, which allow for the attachment of accessories like clamps or pipes. This facilitates a smooth and efficient transfer of concrete from the pump to the desired location. Additionally, the spectacle plate may also have adjustable elements that enable positioning and alignment adjustments, ensuring precise placement of the concrete. In summary, the spectacle plate is essential for maintaining the stability and functionality of the concrete pump, thereby contributing to the successful completion of construction projects.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- The pumping efficiency can be significantly affected in various ways by a piston that is damaged. To begin with, reduced pumping capacity can result from decreased power and force exerted by the pump due to a damaged piston. The piston's responsibility is to generate the necessary pressure for pushing the concrete mixture through the pumping system. If it is damaged, it may fail to generate adequate pressure, leading to slower and less efficient pumping. In addition, leaks can occur within the pump system due to a damaged piston. The piston plays a critical role in sealing the concrete and preventing it from leaking back into the hopper. If it is damaged or worn out, a tight seal may not be created, resulting in leakage. This not only leads to material loss but also reduces pumping efficiency as the pump has to compensate for the loss by working harder. Moreover, blockages and clogs can be caused by a damaged piston in the pumping system. The movement of the piston creates suction, which pulls the concrete mixture into the pump. If the piston is damaged, it may not create sufficient suction, causing the mixture to flow unevenly or get stuck in the system. This can cause delays and interruptions in the pumping process, ultimately reducing overall efficiency. In conclusion, the pumping efficiency can be negatively impacted by a damaged concrete pump piston through reduced power and force, leaks, and blockages. It is crucial to regularly maintain and promptly repair or replace damaged pistons to ensure optimal pumping performance and efficiency.

- Q: How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary depending on several factors such as the brand, type of part, and the supplier. On average, concrete pump spare parts can range from a few hundred dollars to several thousand dollars. Common spare parts such as pistons, seals, and wear plates tend to have lower price points, while more complex components like hydraulic cylinders or control boards can be more expensive. Additionally, the quality and durability of the spare part can also affect the price. It is advisable to compare prices from different suppliers and consider factors like warranty and customer reviews before making a purchase.

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts do come with a warranty. The warranty period may vary depending on the manufacturer and the specific part being purchased. Generally, reputable manufacturers and suppliers offer warranties on their spare parts to provide assurance to customers about the quality and reliability of the product. It is important to carefully review the terms and conditions of the warranty to understand what is covered and for how long. If any defects or issues arise during the warranty period, customers can typically get a replacement or have the part repaired at no additional cost.

- Q: What is the function of a concrete pump remote control antenna?

- The function of a concrete pump remote control antenna is to establish a wireless connection between the remote control device and the concrete pump. This allows the operator to remotely control the various functions of the concrete pump, such as starting and stopping the pump, adjusting the speed and flow of the concrete, and controlling the boom movements. The antenna receives signals from the remote control device and transmits them to the concrete pump, enabling the operator to control the pump from a safe distance. This helps improve efficiency, accuracy, and safety on construction sites by allowing the operator to have better visibility of the pump and its surroundings while still maintaining full control over its operations.

Send your message to us

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords