Colored Corrugate GI Coated Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored Corrugate GI Coated Roofing Sheet

Description for Colored Corrugate GI Coated Roofing Sheet

PPGI Coil | Width | Thickness | Zinc Thickness | Face | Back |

600mm-1250mm | 0.12mm-0.8mm | 30-120g | 15-25u | 5-13u | |

Color | Raul color card , or your model color | ||||

Coil Weight | 3Ton--5Ton . | ||||

Packing | standard export packing . | ||||

Payment Terms | T/T, L/C , | ||||

Trade Terms | FOB , CNF/CFR, CIF | ||||

Loading Port | Qingdao /Tianjin ,China | ||||

Delivery Time | 25days base on order quantity | ||||

Main Structure for Colored Corrugate GI Coated Roofing Sheet:

Thickness :0.18mm-0.8mm

Application: for the construction industrial :

Building construction.

portable roofing.

side plate .

Steel grade: prepainted coil .

galvanized coil .

FAQ

Why should you choose us :

Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

Advantages of Colored Corrugate GI Coated Roofing Sheet :

Rich experiences------------- more than 13 years experience in steel industry.

Alibaba Golden Supplier-----factory recognized ISO certificates etc.

Professional sales team------International trade teams for your service .

7/24 service for you------------all questions will be deal with within 24 hours .

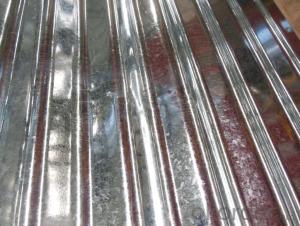

Picture:

- Q: What is the typical elongation of a steel sheet?

- The typical elongation of a steel sheet can vary depending on various factors such as the type of steel, its thickness, and the specific manufacturing process. However, in general, the elongation of a steel sheet is typically around 20% to 40%, meaning it can stretch or deform by that percentage before breaking or rupturing.

- Q: How durable are steel sheets?

- Steel sheets are highly durable and able to withstand various environmental conditions, including extreme temperatures, moisture, and corrosion. They have a long lifespan and are resistant to impact, making them ideal for a wide range of applications.

- Q: Can the steel sheets be easily welded?

- Yes, steel sheets can be easily welded. Welding is a common method used to join steel sheets together. The process involves melting the edges of the steel sheets and then allowing them to cool and solidify, creating a strong bond. However, it is important to note that the ease of welding can depend on the type and thickness of the steel sheets, as well as the skill and experience of the welder. Additionally, proper safety precautions and welding techniques should be followed to ensure a successful and safe welding process.

- Q: Are the steel sheets suitable for welding or fabrication purposes?

- Yes, steel sheets are suitable for welding or fabrication purposes. Steel is a versatile and commonly used material in various industries, including construction, automotive, and manufacturing. Steel sheets provide a strong and durable base for welding and fabrication processes. They can be easily cut, shaped, and joined together through welding techniques such as arc welding, MIG welding, or TIG welding. Steel sheets also offer excellent structural integrity and can withstand high temperatures and mechanical stress during welding or fabrication. Additionally, steel sheets are available in different thicknesses and grades, allowing for customization based on specific welding or fabrication requirements.

- Q: What is the maximum size of the steel sheets available?

- The maximum size of the steel sheets available can vary depending on the specific supplier or manufacturer. Generally, steel sheets can be found in a range of sizes, with widths typically ranging from 36 inches to 72 inches, and lengths ranging from 96 inches to 240 inches. However, it is important to note that these dimensions may vary based on the supplier's capabilities and the specific requirements of the customer. Therefore, it is advisable to contact a supplier or manufacturer directly to inquire about the maximum size of steel sheets they can provide.

- Q: Can the steel sheets be easily formed into curves or angles?

- Sheet metal bending is a process commonly employed to shape steel sheets into curves or angles. Specialized tools like brakes or press machines are utilized to achieve the desired form. The capacity to create curves or angles depends mainly on the thickness and type of steel employed. Generally, thinner and more malleable steel sheets are easier to handle and can be molded into tighter curves or angles. Conversely, thicker and less malleable steel sheets might necessitate greater force and advanced machinery to accomplish the desired shape.

- Q: What is the difference between a standard and high-strength steel sheet?

- The main difference between a standard and high-strength steel sheet lies in their mechanical properties. High-strength steel sheets have a higher yield strength and tensile strength compared to standard steel sheets. This means that high-strength steel sheets can withstand greater forces and pressure before deformation or failure occurs. They are commonly used in applications where durability and load-bearing capacity are critical, such as in automotive and construction industries. Standard steel sheets, on the other hand, have lower strength properties but are often more cost-effective and suitable for less demanding applications.

- Q: Are steel sheets non-magnetic?

- Steel sheets are not necessarily non-magnetic. Their magnetic properties are contingent upon the composition and processing of the steel. Various types of steel, like austenitic stainless steel, lack magnetism, whereas ferritic and martensitic stainless steel can possess it. Additionally, external factors like temperature and magnetic fields can impact the magnetism of steel sheets. Thus, it is crucial to assess the type and characteristics of the steel sheet to ascertain its magnetic behavior.

- Q: What are the different surface finishes for stainless steel sheets?

- Some of the different surface finishes for stainless steel sheets include brushed, mirror, satin, and bead blasted finishes.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Yes, steel sheets can be used for manufacturing machinery parts. Steel is a versatile and durable material that offers excellent strength and rigidity, making it suitable for producing various machinery components. Steel sheets can be easily formed, cut, and welded to create complex shapes and structures required for machinery parts. Additionally, steel has good corrosion resistance, ensuring the longevity of the machinery components. Steel sheets also provide dimensional stability and can withstand heavy loads and high temperatures, making them an ideal choice for manufacturing machinery parts.

Send your message to us

Colored Corrugate GI Coated Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords