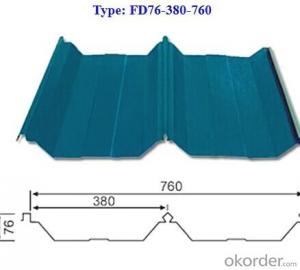

colour coated coils,colour coated steel coil,corrugated steel roofing sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC DX51D | Thickness: | 0.146-1.2mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | 0.146MM-1.2MM*1250MM OR UNDER |

| Type: | Steel coil ,Steel sheets/plates,Corrugated steel sheets/plates | Technique: | Hot rolled-cold rolled- galvanized Surface Treatment Galvanized | Surface Treatment: | Galvanized |

| Application: | Structural use ,roofing, commercial use, household appliance, industry | Special Use: | High-strength Steel Plate | Width: | 800-1250mm |

| Length: | C |

Packaging & Delivery

| Packaging Detail: | standard packing to export 4 eye bands and 3 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumfer |

| Delivery Detail: | 7--30days after receiving deposit |

Specifications

Color Coated Steel Coil:SGCC DX51D

Capability:Waterproof Rustless

Place of Origin:Shandong, China (Mainland)

Our Product Introduction

Hot-Dipped Galvanized Steel Coil:SGCC DX

Thickness: 0.146-1.2mm

Width:800-1250mm

Spangle: Regular Big Mini Non-spangle

CNBM INTERNATIONAL

CNBM International Corporation (CNBM International) is the most important trading platform of

CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets

Supervision and Administration Commission of the State Council.

As of the end of 2012, CNBM’s total assets exceeded RMB 300 billion, with more than 150,000

employees, and 20 companies under direct management with 100% share control or majority control,

among which 6 were listed companies, including 2 overseas listed. CNBM ranked NO.319 in the Top

Fortune World 500 of 2013 with 34.46 billion dollars revenue.

For now, we have established strategic partnerships with hundreds of domestic manufacturers and

extensive business relations with clients from over 120 countries in the fields of building materials and

equipments by making full use of its absolute superiority in both abundant source and solid technology

support. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view

to realize localization, which also represents an essential progress in our globalization target.

STEEL SHEET/COIL DEPARTMENT

Our department is specialized in manufacturing and exporting the following products.

HOT ROLLED STEEL

COLD ROLLED STEEL

HOT-DIP GALVANIZED/ALUZINC STEEL

PRE-PAINTED GALVANIZED/ALUZINC STEEL

PRINTING STEEL

We can ensure that stable quality standards are maintained, strictly meeting both market

requirements and customers’ expectations. Our products enjoy an excellent reputation and have been

exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely

hope to establish good and long-term business relationship with your esteemed company.

COMPANY

PROFILE

- 1 -

- 2 -

Steel Coil/Sheet

CNBM UAE

CNBM INDIA

CNBM GERMANY

CNBM BRAZIL

CNBM K.S.A

CNBM INDONESIA

CNBM THAILAND

CNBM SOUTH AFRICA

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- I advise you not to as it will damage your guitar :) they do sound way better but that's what an acoustics for

- Q: What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include mill finish, pickled and oiled, galvanized, painted, and textured.

- Q: What is the strongest steel ever made.

- I'm a civil/structural engineer. ASTM A 416 is one of the strongest steels, with a nominal yield stress of 243,000 psi and design ultimate strength of 270,000 psi. This steel is commonly used in pre-stressing and post-tensioning of concrete structures. See the link below to one manufacturer of strands and bars made with this type of steel.

- Q: How are steel coils inspected for quality?

- Steel coils are inspected for quality through various methods such as visual inspection, dimensional measurement, and non-destructive testing techniques. These inspections ensure that the coils meet specific quality standards and requirements by examining their surface condition, dimensions, and internal integrity.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Steel shafts should have a shaft band just below the grip area on the shaft....Graphite should have a label that looks like it is a Decal that is readable on the shaft. If still confused take to any good golf store...they will be able to Identify the shaft material in no time at all

- Q: What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils used in automotive part manufacturing can vary depending on the specific application and manufacturer. However, commonly used dimensions for steel coils in automotive part manufacturing range from 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can also vary, typically ranging from several meters to several hundred meters. It is important to note that these dimensions are not fixed and can be customized to meet the specific requirements of each automotive part being manufactured.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- Quenching results in smaller grains than air cooled. This means more boundaries, which means harder steel.

- Q: How are steel coils inspected for uniformity?

- To ensure uniformity, steel coils undergo a series of visual and mechanical tests. First, the coil's external appearance is carefully examined for any visible defects like dents, scratches, or rust. This is crucial to maintain the coil's integrity and prevent potential issues during further processing. Next, non-destructive testing techniques such as ultrasonic or magnetic particle inspection are used to measure the coil's thickness at various points. This helps identify any variations in thickness that could affect the overall quality and performance of the coil. Precise instruments are also employed to measure the coil's width and ensure it adheres to the required specifications. This is important for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. Weighing scales or load cells are typically used for this purpose, ensuring consistent weight that meets the required standards. For internal inspection, steel coils may undergo eddy current testing, a non-destructive method that detects surface and near-surface defects. By utilizing electromagnetic induction, this technique can identify irregularities in the metal, such as cracks, voids, or inclusions. In summary, a comprehensive combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures thorough inspection for uniformity in steel coils. These rigorous processes guarantee the quality and reliability of the coils, enabling them to meet industry standards and customer requirements.

Send your message to us

colour coated coils,colour coated steel coil,corrugated steel roofing sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords