Colorful Corrugated GI Galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

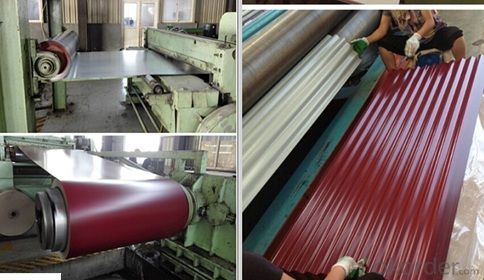

Colorful Corrugated GI Galvanized Steel Sheet

Galvanized Corrugated Steel Roofing Sheet is formed by cold roll machine, using galvanized steel sheet or aluminum steel as the base material .Galvanized corrugated steel roofing sheet is featured with easy installation ,high strength ,more economic .( low cost )

Product Features

.Outlook Beautiful and novel, rich colors, flexible combination, can be used in different buildingto express special original architectural styles in life.

.Surface have been treated as galvanized and color coated.so it can anti-rain,anti- fire,anti-quake,So it has a long term life as 20-30 year and color just not fade.

. Light weight: easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings.

.Smooth surface treatment,the dust will be easy taken off by the rain.

. Environmental material,can be used many times,will do no hard to the our environment.

Product Specification

.Thickness:0.13mm to 0.8mm

.Length: 1m to 11.8m.

. Color: navy blue,white grey and any RAL colors.

. Certification: ISO9001:2000.

.Material : cold rolled galvanized steel coil.

. Standard: JIS,DX51D,SGCC,Q235. A653

. advantage: waterproof,light weight, high strength,best price.

. HS code: 7210700000

Packing Information (For 27.5 Tons heavy 20’Fcl)

. water proof paper packing in side

. plastic film Packing in middle

. steel sheet Packing out side

.several steel strip packing to fix the packing

Production Line & Package

FAQ

1. how many wave for per pcs

—— some wave is 8 ,same wave is 9 ,save wave is 11 ,it is up to your request

2. What is the MOQ for this products ?

—— Normally the MOQ is 25mt per size and per color .

- Q: Can steel strips be used in the production of jewelry?

- Yes, steel strips can be used in the production of jewelry, particularly for industrial or unconventional designs. However, it is not as common as other materials like gold, silver, or platinum, as steel strips are typically associated with more rugged or utilitarian products.

- Q: How are steel strips used in the production of air conditioning systems?

- Steel strips are used in the production of air conditioning systems in various ways. One of the primary uses is for the construction of the outer casing or housing of the air conditioning unit. The steel strips are formed into panels or sheets that provide a durable and protective covering for the internal components of the system. Additionally, steel strips are often used in the manufacturing of the heat exchangers, which are crucial components in air conditioning systems. The heat exchangers are responsible for transferring heat between the indoor and outdoor environments, allowing the air conditioning unit to cool or heat the air as required. Steel strips are used to create the finned surfaces of the heat exchangers, which maximize the surface area available for heat transfer. Furthermore, steel strips are also utilized in the fabrication of various brackets, supports, and frames within the air conditioning system. These components provide structural stability and ensure the proper positioning and alignment of the different parts of the unit. Steel's strength and rigidity make it an ideal material for these applications. In summary, steel strips play a vital role in the production of air conditioning systems. They are used for the construction of the outer casing, the manufacturing of heat exchangers, and the fabrication of various brackets and supports. The use of steel in these applications ensures the durability, efficiency, and overall performance of air conditioning units.

- Q: Can steel strips be used in HVAC ductwork?

- Yes, steel strips can be used in HVAC ductwork. Steel strips are commonly used as reinforcement for the joints and seams in ductwork, helping to maintain the structural integrity and prevent air leaks.

- Q: What are the environmental impacts of steel strip production?

- The environmental impacts of steel strip production are significant. The process involves high energy consumption, which contributes to carbon emissions and climate change. Additionally, the mining and extraction of iron ore, along with the production of coke and coal, result in habitat destruction and air pollution. Steel strip production also generates large amounts of waste, including slag and mill scale, which can contaminate soil and water bodies. Overall, it is crucial to implement sustainable practices and technologies to mitigate these environmental impacts.

- Q: How are steel strips embossed or patterned?

- Steel strips can be embossed or patterned through various techniques. One common method is through the use of embossing rolls or dies. These rolls or dies are engraved with specific patterns or designs, which are then pressed onto the steel strip under high pressure. This process creates raised or recessed areas on the surface of the strip, resulting in the desired pattern or design. Another technique used is called laser engraving. In this method, a laser beam is directed onto the steel strip, selectively removing material to create the desired pattern. This process allows for intricate and precise designs to be achieved. Additionally, steel strips can also be patterned using chemical etching. A resist material is applied to the surface of the strip, protecting certain areas from the etching solution. The strip is then immersed in the etching solution, which selectively removes material from the unprotected areas, resulting in the desired pattern. Overall, steel strips can be embossed or patterned using a variety of techniques such as embossing rolls or dies, laser engraving, and chemical etching. These methods offer flexibility in design options and can create visually appealing and functional patterns on steel strips.

- Q: What are the different surface etching methods for steel strips?

- For steel strips, there exist several surface etching methods that can be employed, depending on the desired outcome and specific application requirements. Some commonly utilized techniques include: 1. Chemical etching: In this process, a chemical solution is applied to the steel strip's surface to eliminate a thin layer of material. The choice of chemical depends on the intended effect, such as achieving a smooth or matte finish. Commonly employed acid solutions include hydrochloric acid or sulfuric acid. 2. Electrochemical etching: This method involves employing an electrical current to selectively dissolve the steel surface. The steel strip is submerged in an electrolyte solution, and a direct current is utilized to create a controlled etching reaction. This technique allows for precise control over the etching process and can be utilized to create intricate patterns or designs on the steel surface. 3. Laser etching: Laser etching is a non-contact method that uses a high-powered laser beam to selectively remove material from the steel strip. This technique is exceptionally precise and can be employed to create intricate markings or patterns on the surface. It is frequently employed for branding or identification purposes. 4. Mechanical etching: Mechanical etching involves physically abrading the steel strip's surface to achieve the desired texture or finish. This can be accomplished using abrasive materials such as sandpaper, wire brushes, or grinding wheels. This method is often employed to eliminate scale or other surface imperfections and to achieve a consistent texture on the steel surface. Each of these surface etching methods possesses its own advantages and limitations, and the selection of the appropriate method depends on factors such as the desired finish, the complexity of the design, and the specific application requirements. It is crucial to carefully consider these factors and consult experts in the field to determine the most suitable method for accomplishing the desired outcomes.

- Q: What are the factors that affect the fatigue resistance of steel strips?

- The fatigue resistance of steel strips can be affected by several factors. These factors include the material composition, surface condition, heat treatment, manufacturing process, loading conditions, environmental factors, and design considerations. The chemical composition of the steel, including impurities and alloying elements, can have a significant impact on its fatigue resistance. For example, higher levels of carbon can increase hardness and strength but may decrease fatigue resistance. The surface finish and quality of the steel strip can also affect fatigue resistance. Scratches, nicks, or corrosion on the surface can act as stress concentrators and initiate fatigue cracks. Proper surface treatments, such as grinding or shot blasting, can reduce stress concentrations and improve fatigue resistance. The heat treatment process used during manufacturing can greatly influence fatigue resistance. Proper heat treatment, such as quenching and tempering, can enhance strength and toughness, thereby improving fatigue resistance. The manufacturing process itself can also impact fatigue resistance. Variables like rolling, annealing, or cold working can introduce residual stresses or microstructural changes that affect fatigue behavior. Proper control and optimization of these processes can enhance fatigue resistance. The type and magnitude of the applied load can influence fatigue resistance. Factors like cyclic stress amplitude, stress ratio, and loading frequency can affect fatigue life. Higher stress amplitudes, stress ratios, and loading frequency can result in reduced fatigue resistance. Environmental factors, such as temperature, humidity, and corrosive agents, can also affect fatigue resistance. Elevated temperatures can accelerate fatigue crack growth, while corrosive environments can promote crack initiation and propagation, leading to reduced fatigue life. The design of steel strips, including their geometry, dimensions, and the presence of stress concentrators, can impact fatigue resistance. Proper design practices, such as filleting sharp corners or adding radius to stress concentration areas, can help improve fatigue performance. In conclusion, the fatigue resistance of steel strips is influenced by various factors. Understanding and optimizing these factors can lead to improved fatigue performance and longer service life.

- Q: Are steel strips suitable for making decorative items?

- Indeed, decorative items can be made using steel strips. These strips possess the ability to be effortlessly molded and crafted into a multitude of designs and patterns, thus rendering them as an incredibly versatile material for the creation of decorative items. Additionally, steel is renowned for its durability and longevity, guaranteeing that these decorative pieces will sustain their magnificence and practicality throughout the passage of time. Furthermore, steel strips can be adorned with paint, polish, or coatings to augment their visual appeal, thereby offering a diverse array of customization options. Whether utilized for wall adornments, sculptures, or alternative decorative elements, steel strips have the capacity to introduce a contemporary and sophisticated essence to any given space.

- Q: How are steel strips used in the manufacturing of construction equipment?

- Due to their high strength, durability, and versatility, steel strips play a crucial role in the production of construction equipment. Throughout the manufacturing process, these strips are utilized in various ways. One way in which steel strips are commonly used is in the fabrication of structural frames. They are often employed to construct the primary framework of construction equipment such as bulldozers, cranes, and excavators. By cutting, shaping, and welding the strips together, a sturdy and robust structure is formed that can withstand heavy loads and operate in demanding conditions. In addition, steel strips are essential in the manufacturing of components such as buckets, blades, and cutting edges for construction equipment. These strips are shaped and formed into the desired shape to ensure that the resulting parts are strong enough to endure the intense forces and wear and tear experienced during construction operations. Moreover, steel strips are of great importance in reinforcing and strengthening attachments and accessories for construction equipment. For instance, they are utilized in the production of hydraulic cylinders, which are critical for the smooth functioning of machinery like cranes and forklifts. By rolling, machining, and welding the strips, cylinder bodies are created, providing the necessary strength and stability. Furthermore, steel strips are employed in the production of tracks and undercarriage components for construction equipment such as excavators and tractors. These strips are shaped into the form of tracks or other undercarriage parts, ensuring that the equipment can traverse various terrains and withstand heavy loads without compromising performance or safety. In conclusion, steel strips are an integral part of construction equipment manufacturing. Their strength, durability, and versatility make them ideal for constructing structural frames, components, attachments, and undercarriage parts. By incorporating steel strips into their manufacturing processes, companies can produce top-quality construction equipment that can endure the challenges of the job site and deliver exceptional performance.

- Q: How do steel strips respond to different corrosion environments?

- Factors such as the type of corrosion, the composition of the steel, and the surrounding conditions can result in varying responses of steel strips to different corrosion environments. When exposed to moisture, oxygen, and aggressive chemicals, steel strips are generally susceptible to corrosion. However, the extent of corrosion can differ depending on the specific environment. In a dry environment with low humidity, significant corrosion of steel strips is less likely. Instead, a superficial layer of rust may develop, which does not affect the steel's structural integrity and can be easily removed. In a humid environment, steel strips are more prone to corrosion. Moisture in the air can cause rust to form on the surface of the steel, leading to deterioration and eventual failure if not addressed. In marine or saltwater environments, the presence of chloride ions makes steel strips highly susceptible to corrosion. These ions can penetrate the protective oxide layer on the steel's surface, accelerating the corrosion process and causing localized damage. Chemicals and industrial atmospheres can also contribute to the corrosion of steel strips. Exposure to acids, alkaline substances, or corrosive gases can result in destructive chemical corrosion, with the severity depending on concentration, temperature, and exposure duration. To prevent corrosion, protective measures can be taken. Coating steel strips with paint or galvanization creates a barrier against moisture and corrosive elements. Regular maintenance, including cleaning, inspection, and anti-corrosion treatments, can prolong the lifespan of steel strips in different corrosion environments. Overall, multiple factors influence how steel strips respond to corrosion environments, and proper prevention and maintenance practices are crucial to minimize the impact of corrosion and ensure the longevity of the steel strips.

Send your message to us

Colorful Corrugated GI Galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords