Aluminum Alloy Coil for Construction - Plain Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Coils Used for Construction

Plain aluminium coils used for construction are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

Plain aluminium coils used for construction can meet the highest standards while save the cost. Our strong quality control term bring you the most-qualified products.

2.Main Features of Plain Aluminium Coils Used for Construction

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

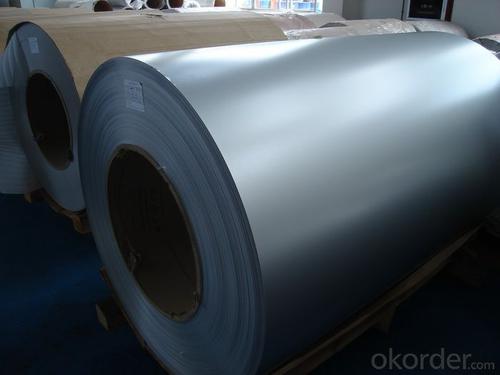

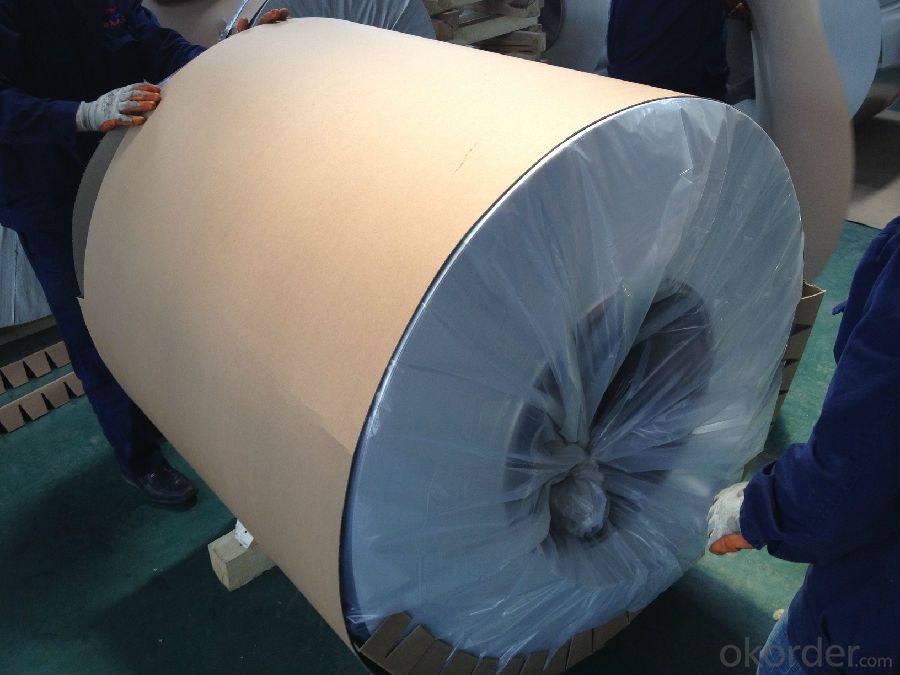

3. Plain Aluminium Coils Used for Construction Images

4.Specification of Plain Aluminium Coils Used for Construction

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5. FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Coils, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Coils in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium Coils?

We have exported aluminum Coils to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How are aluminum coils protected against UV exposure during storage?

- During storage, aluminum coils are typically safeguarded against UV exposure through the application of a protective coating or the use of UV-resistant packaging materials. UV degradation poses a significant risk to the coils, leading to discoloration, surface damage, and reduced performance. Consequently, manufacturers and distributors take special precautions to shield the coils from harmful UV rays. One popular approach involves applying a protective coating on the coil surface. This coating acts as a barrier between the aluminum material and UV radiation, preventing direct exposure. Usually, the coating consists of a specialized paint or lacquer that contains UV inhibitors. These inhibitors either absorb or reflect UV rays, minimizing damage to the coils. Furthermore, this protective layer preserves the aesthetic appearance of the coils and extends their lifespan. Aside from coatings, UV-resistant packaging materials can also be used to store aluminum coils. These materials are specifically designed to block or absorb UV radiation, creating a shield around the coils. Polyethylene films are a common choice for UV-resistant packaging, as they provide excellent UV protection. By storing the coils in such packaging, they are effectively safeguarded against direct sunlight and other sources of UV radiation. It is important to note that UV protection measures become particularly crucial during long-term storage or transportation, as the coils may be exposed to UV rays for extended periods. By implementing these protective measures, manufacturers and distributors ensure that the aluminum coils maintain their quality and performance, even when stored in environments with high UV exposure.

- Q: Why 5052 turn black after annealing during the production of aluminum alloy?

- The aluminum oxide in the surface has been oxidized by other chemical elements.

- Q: Are aluminum coils suitable for coil winding applications?

- Coil winding applications can utilize aluminum coils, as they possess numerous advantageous properties. Firstly, aluminum is lightweight, facilitating easier handling and transportation. Industries like automotive and aerospace, which prioritize weight reduction, find this particularly beneficial. Moreover, aluminum exhibits excellent conductivity, ensuring efficient electrical current flow within the coil. This is especially advantageous for applications requiring high performance and low resistance, such as transformers and electric motors. Additionally, aluminum's high resistance to corrosion renders it suitable for outdoor and harsh environments. Unlike metals like steel, it does not rust and can endure exposure to moisture and chemicals. Furthermore, aluminum coils offer cost-effectiveness. Compared to metals like copper, commonly used in coil winding, aluminum is generally more affordable. Thus, it presents a cost-efficient option for various industries. Nevertheless, it is important to acknowledge that aluminum has lower electrical conductivity than copper. Therefore, in applications where high conductivity is paramount, such as power transmission, copper coils may be more suitable. Nonetheless, aluminum coils provide numerous benefits and find widespread use in various coil winding applications.

- Q: What is the modulus of elasticity of aluminum coils?

- The modulus of elasticity of aluminum coils, also known as Young's modulus, is a measure of the material's stiffness and its ability to resist deformation under an applied load. The modulus of elasticity for aluminum coils is typically around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value may vary slightly depending on the specific alloy and temper of the aluminum used in the coils. The modulus of elasticity helps determine the strength and flexibility of aluminum coils, making it an important factor in various applications such as construction, automotive, and aerospace industries.

- Q: Can aluminum coils be used in automotive suspension systems?

- Automotive suspension systems can utilize aluminum coils. Aluminum, a lightweight and sturdy material, provides numerous advantages for suspension components. Its high strength-to-weight ratio allows it to handle heavy loads without burdening the vehicle with unnecessary weight. This can enhance fuel efficiency and overall performance. Furthermore, aluminum is resistant to corrosion, making it particularly valuable for automotive suspension systems exposed to harsh weather conditions and road debris. By incorporating aluminum coils, manufacturers can ensure that suspension components have a longer lifespan and require less maintenance. In addition, aluminum coils possess superior heat absorption and dissipation capabilities compared to materials like steel. This aids in preventing overheating and mitigating the risk of suspension failure, especially during intense driving conditions or off-road usage. However, it is important to note that the use of aluminum coils in automotive suspension systems may entail certain compromises. Although aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must meticulously design and engineer the suspension system to ensure it can withstand necessary loads and provide sufficient support and stability for the vehicle. In summary, aluminum coils can be effectively employed in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. Nevertheless, manufacturers must carefully consider the specific requirements and trade-offs associated with aluminum usage in suspension components to ensure optimal performance and safety.

- Q: How do aluminum coils perform under low-temperature applications?

- Aluminum coils are known for performing exceptionally well under low-temperature applications. Due to its inherent properties, aluminum is highly resistant to low temperatures and can maintain its structural integrity even in extreme cold conditions. The low thermal expansion coefficient of aluminum allows it to contract and expand without compromising its performance, making it an ideal choice for various low-temperature applications. One of the key advantages of aluminum coils in low-temperature applications is their ability to resist corrosion. Aluminum naturally forms a protective oxide layer that prevents it from rusting or corroding, even in cold and wet environments. This makes aluminum coils highly durable and ensures their longevity, even when exposed to low temperatures for extended periods. Additionally, aluminum has excellent thermal conductivity, which means it effectively transfers heat even at low temperatures. This property is crucial in applications such as refrigeration and air conditioning, where efficient heat transfer is required to maintain the desired temperature levels. Aluminum coils can effectively dissipate heat, ensuring optimal performance in low-temperature environments. Furthermore, aluminum coils are lightweight, which makes them easier to handle and install in low-temperature applications. Their lightweight nature also contributes to energy efficiency, as less energy is required to transport and operate the equipment using aluminum coils. In summary, aluminum coils perform exceptionally well under low-temperature applications. Their resistance to corrosion, thermal conductivity, durability, and lightweight nature make them an ideal choice for various industries, including refrigeration, air conditioning, and low-temperature processing.

- Q: What is the weight of an aluminum coil?

- The weight of an aluminum coil can vary depending on its size, thickness, and length. On average, aluminum coils typically weigh between 1,500 and 6,000 pounds. However, it is essential to note that specific aluminum coils can weigh more or less depending on the specific requirements and specifications of the coil.

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- No, aluminum foil and aluminum cookware are safe to cook with. Back in the 1930s to as late as the 1960s, a certain screwball religious cult sometimes published articles to fluff out their newsletters and proselytizing magazines about the supposed dangers of aluminum cookware. Their source was anecdotes from one obsessive quack, not any replicable scientific studies.

- Q: Does anyone know if aluminum skateboards are good?

- aluminum skateboards are ok if your just olling and playing around on them. but if your a real skater you'll probably want to get a real one.

- Q: i am thnking of building my own aluminum john boat and using the propulsion from a jetski to power it, i was wondering if anyone had taken on a project like this and had a few pieces of advice to offer while i am still in the planning stages. the biggest concern i have right now involves the tunnel for the intake, should i use the original fiberglass from the jetski or build up a tunnel out of aluminum for it?

- 518 okorder /

Send your message to us

Aluminum Alloy Coil for Construction - Plain Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords