Color Coated Pre-Painted Steel Sheet or Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

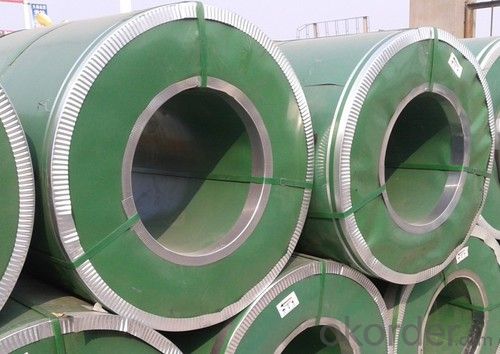

3. Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry. They are often utilized in the manufacturing and assembly of various aircraft components such as engines, frames, and landing gears. Steel coils provide strength, durability, and resistance to high temperatures, making them suitable for aerospace applications.

- Q: How do steel coils contribute to the energy storage industry?

- Steel coils play a vital role in the energy storage industry by serving as a key component in large-scale energy storage systems such as pumped hydro storage and compressed air energy storage. These coils are used in the construction of storage tanks and pressure vessels, which are essential for storing and releasing energy on demand. Additionally, steel coils are also utilized in the manufacturing of battery systems used in grid-scale energy storage applications, providing structural support and ensuring safety and reliability.

- Q: How are steel coils inspected for surface cleanliness?

- Steel coils are inspected for surface cleanliness through a variety of methods including visual inspection, magnetic particle inspection, and ultrasonic testing. Visual inspection involves visually examining the surface for any visible contaminants or defects. Magnetic particle inspection uses magnetic fields and particles to detect surface defects such as cracks or flaws. Ultrasonic testing uses high-frequency sound waves to detect any subsurface defects or irregularities. These inspection methods ensure that the steel coils meet the required standards of cleanliness and quality.

- Q: Like 49ers. Pittsburgh have long history of steel industry?

- www.okorder A basement waterproofing New Jersey contractor is the one that you need to ensure that your entire home's foundation will not get damped with water and to avoid expensive repairs at the same time.

- Q: What are the common packaging defects in steel coils?

- Some common packaging defects in steel coils include: 1. Edge damage: This occurs when the edges of the steel coil are not properly protected or wrapped, leading to dents, scratches, or even deformities along the edges. Edge damage can compromise the integrity of the coil and may result in reduced performance or structural issues. 2. Rust or corrosion: Steel coils are susceptible to rust or corrosion if they are not adequately protected during packaging. Exposure to moisture or harsh environmental conditions can lead to oxidation, resulting in the formation of rust spots or even widespread corrosion. This can weaken the steel and render it less suitable for its intended use. 3. Coil slippage: Improper packaging can cause the coils to shift or slip within the packaging material during handling or transportation. This can lead to misalignment, deformation, or interlocking of the coils, making them difficult to separate or use effectively. 4. Coil damage during handling: Rough handling, improper lifting techniques, or inadequate support can cause mechanical damage to the steel coils. This can result in dents, scratches, or even more severe structural damage, which may impact the functionality or performance of the steel coil. 5. Inadequate protection against impacts: Steel coils need to be adequately protected against impacts during transportation or storage. Insufficient padding or cushioning can lead to impacts or collisions, resulting in deformities, dents, or even fractures in the coil. 6. Improper coil strapping or banding: If the strapping or banding used to secure the steel coils is not properly applied or tightened, it can result in coil slippage or even complete unraveling of the packaging. This can lead to a tangled mess of steel coils, making them difficult to handle, transport, or use. 7. Insufficient labeling or identification: Proper labeling and identification are essential for efficient handling, storage, and tracking of steel coils. Inadequate or incorrect labeling can lead to confusion, delays, or even loss of the coils during transportation or storage. To avoid these common packaging defects, it is crucial to follow proper packaging guidelines, use appropriate packaging materials, provide adequate protection, and ensure proper labeling and identification of steel coils. Regular inspections and quality checks throughout the packaging process can help identify and rectify any defects before the coils are shipped or used.

- Q: In the warehouse management system of steel coil

- Warehouse is an important component of enterprise material supply system. It is also the tache of enterprise material circulation and storage, and it also undertakes many functions of material management. Its main tasks are to keep the stock well, to be accurate, to be of good quality, to ensure safety, to prompt the people, to produce, to be considerate, to reduce costs, and to speed up capital turnover.

- Q: How are steel coils used in the manufacturing of flooring materials?

- Steel coils are commonly used in the manufacturing of flooring materials as they provide structural support and durability. The steel coils are typically used as a base layer that is sandwiched between other materials, such as wood or vinyl, to create a strong and sturdy flooring surface. The coils help to distribute weight evenly and prevent the flooring from sagging or warping over time. Additionally, the steel coils can also enhance the impact resistance and overall lifespan of the flooring, making it suitable for high-traffic areas.

- Q: How are steel coils used in the production of metal ductwork?

- Steel coils are used in the production of metal ductwork as they provide a continuous and flexible supply of raw material. These coils are unrolled, cut, and shaped into specific dimensions to create the ductwork components. The steel's strength and durability make it suitable for handling high air flows and maintaining structural integrity, ensuring efficient airflow in heating, ventilation, and air conditioning (HVAC) systems.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- You know, I'd have to say it's very complex.

- Q: What is the material of steel coil 08F and what brand can be used instead?

- 20 steel used for various mechanical parts is not subjected to great stress and toughness, such as rod, sleeve, screw, lifting hook; also can be used for manufacturing in 60 pressure and 450 DEG C using non corrosive medium pipes, pipe; can also be used for carbon and cyanide carburized core strength is not the chain, such as bushings, roller, shaft and gear, sprocket and other important.

Send your message to us

Color Coated Pre-Painted Steel Sheet or Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords