Color Coated PPGI for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:CGCC CGCH

Standard:ASTM, JIS, GB, AISI

Steel Grade:Q195 Q235

Certification:ISO, SGS, BV, RoHS

Surface Treatment:Galvanized

Technique:Cold Rolled

Edge:Mill

Stock:Stock

Thickness:0.15-0.8mm

Width:800mm-1250mm

Zinc Coating:30-120G/M2

Coil Weight:3-6 Tons

Type of Coating:Galvanized

Dlivery Time:in 30 Days

MOQ:25 Mt

Export Markets:Global

Additional Info.

Packing:Standard Seaworthy Package

Standard:0.15-0.8mm*800-1250mm

Origin:Shandong Province. China

HS Code:7210701000

Production Capacity:300000 Tons / Year

Product of Description

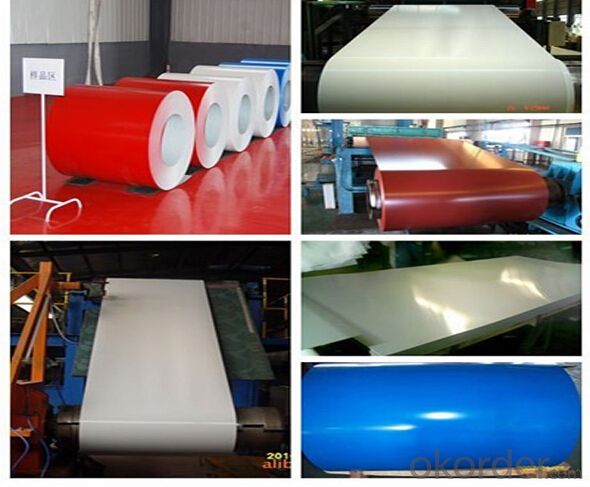

NAME: Color Coated Galvanized Steel Coil/PPGI

SIZE:

Thickness: 0.12-1.2mm

Width: 600mm-1250mm (STD914mm,1000mm, 1200mm, 1219mm, 1250mm)

Thickness tolerance: +/-0.02mm or control in 0.1 according to customer's requirement

Width tolerance: +/-2mm

Zinc, Paint & Color

Zinc coating: 30-120G/M2

Paint thickness: Top 13-20um + Back 5-10um

Color: As the RAL color standard or customer's sample

Hardness: normal hard (HRB 65); full hard (HRB95) or as per your request

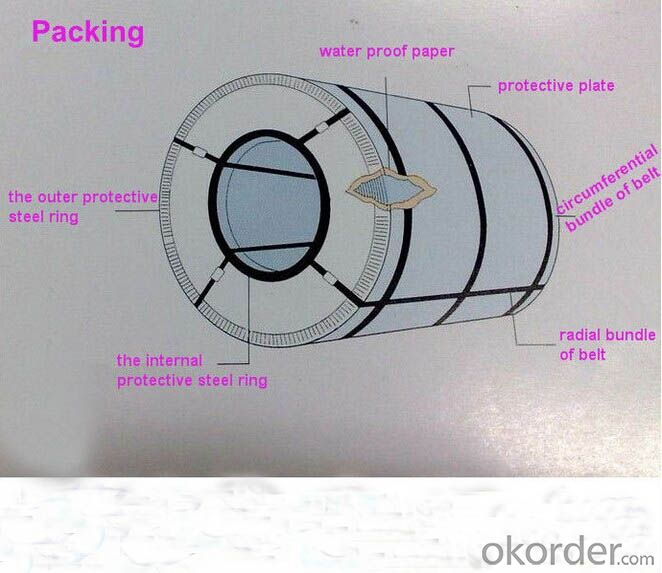

Packing

1. Coil weight: 3-6 tons

2. Coil ID: 508mm\610mm

3. Inner side: By water proof kraft paper and plastic packing.

4. Outside: Covered by steel sheet, bundled the sheets with steel strips.

5. Standard sea worthy package or special packing method as per your request

Standard

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: Galvanized steel coils\ Galvalume steel, such as SGCC, CGCC, DX51D+Z, Q195,etc

Base metal: Hot galvanized steel or PrePainted Galvanized aLuminium steel or HBR>85

Techinque: Cold rolled, hot-dipped galvanizing, color coated

Quality: CQ DQ prime

Payment and Delivery Time

1. Payment: 30% T/T as deposit and 70% balance irrevocable L/C at sight or nogotiate

2. Delivery Time: 10-20 days after recepit of 30% T/T.

Application

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

| Commodity | Color Coated Galvanized Steel Coil/PPGI |

| Techinical Standard | ASTM, JIS, GB, AISI, DIN, BS |

| Grade | Q195 Q235 Q235B SGCC DC51D DC52D DC51D+Z |

| Thickness | 0.15-0.8mm |

| Width | 800-1250mm |

| Coil weight | 3-6tons |

| Type of coating | Galvanized |

| Zinc coating | 30-120G/M2 |

| Coil ID | 508mm or 610mm |

| MOQ | 25 MT |

| Supply capacity | 300000MT/per year |

| Package | standard sea worthy package |

| Origin | Shandong Province.China |

| Trademark | yuanda |

| Application | Industrial panels, roofing and siding for painting |

| Price terms | FOB, CFR, CIF |

| Payment terms | 30%T/T in advance+70% T/T or irrevocable 100% L/C at sight |

| delivery time | 10-20 days after recepit of 30% T/T |

| Remarks | Insurance is all risks |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- In your choices carbide steels are used for milling and drilling purposes and high speed steel are used in lathe operations. For shaping the tools, tool grinding machines are used and for initial sharing dyes are used.

- Q: Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale.Compute the probability that the hardness of a randomly selected steel specimen is less than 60. a..462b..333c..500d.2e..750 Question 8 Refer to question 7. Compute the probability that the hardness of a randomly selected steel specimen is between 70 and 75.a..167b..500c..063d..100e..

- Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale. That would be... f(x) = 1/(80 - 50), 50 ≤ x ≤ 80 . . . . . 0 elsewhere Consider this following problem.. Compute the probability that the hardness of a randomly selected steel specimen is less than 60. Here, we have... P(x 60) Oh! Know that the mean and the standard deviation of the uniform distribution function are... ? = (a + b)/2 σ = (a - b)?/12 You should get... ? = 65 σ = 75 Now... P(z (60 - 65)/75) = P(z -0.07) Hence, you should get around 0.462. Good luck!

- Q: How are steel coils used in the manufacturing of industrial machinery?

- Steel coils are used in the manufacturing of industrial machinery as raw material for various components, such as frames, brackets, and supports. The coils are processed by cutting, bending, and shaping to create specific parts that provide stability, strength, and structure to the machinery. Additionally, steel coils are often used for creating gears, shafts, and other moving parts that require high durability and resistance to wear and tear.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using heavy-duty cranes and specialized equipment. When loading, the coils are lifted from the dockside or storage area using a crane with strong lifting capacity. They are carefully positioned onto the ship's deck, ensuring proper balance and securement to prevent any damage during transit. Unloading is done in a similar manner, with the crane carefully lifting the coils from the ship's deck and placing them onto the dock or designated storage area. Throughout the process, safety protocols are followed to ensure the smooth and efficient handling of these heavy and valuable cargo.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: What kind of insulation should be used in a steel building?

- Vinyl fiberglass insulation is getting popular with the steel building industry. The vinyl fiberglass insulation offers a shining look to the building and is resistant to dust as well as condensation. Effective ventilation inside the steel building can also help in preventing the condensation process inside the building. Besides, the building doors should be insulated effectively so as to minimize the heat loss. Be sure to seal all the door gaps in the building. All these steps are necessary to follow to get an effectively insulated steel building.

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- In okorder /

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel coil is a kind of steel plate, also known as coil.The coil, like toilet paper, can roll into a barrel. (describe not very appropriate)When the coil is used, it is necessary to use the Kaiping machine to expand into a flat plate.

- Q: Where can I find a great deal online for Danesco Stainless Steel Egg Poacher

- looks like Target is going to be your best bet for about $35

Send your message to us

Color Coated PPGI for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords