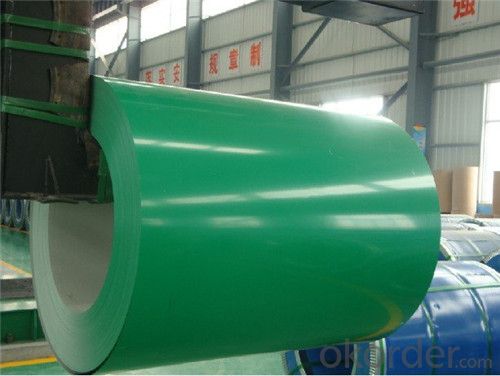

Color coated Galvanized Cold rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Grade | Chemical composition % | |||||||||

| C | Si | Mn | P | S | Alta | Ti | Nb | |||

| No more than | No more than | No more than | No more than | No more than | No less than | No more than | No more than | |||

| DC51D+Z,DC51D+ZF | 0.1 | --- | 0.5 | 0.035 | 0.035 | --- | --- | --- | ||

| (St01Z,St02Z,St03Z) | ||||||||||

| Grade | Mechanical properties | plating adhesion | ||||||||

| yield strength | tensile strength | n 90 | r 90 | Elongation % | Plating weight(g/m 2 ) | |||||

| Mpa | Mpa | No less than | No less than | No less than | Bending diameter | |||||

| (a=thickness of slab) | ||||||||||

| L 0 =80mm b=20mm | ||||||||||

| Normal thickness mm | ||||||||||

| ≤ 0.7 | >0.7 | ≤ 140/140 | >140/140~ | >175/175 | ||||||

| 175/175 | ||||||||||

| DC51D+Z(St01Z,St02Z,St03 Z), DC51D+ZF | --- | 270~500 | --- | --- | 20 | 22 | 0a | 1a | 2a | |

| Exposure Test : | Salt Spray Test : | |||||||||

| Environment | GI | Enviroment | GI Average Corrosion | AL-ZN Average Corrosion | ||||||

| Average corrosion | ||||||||||

| g/m2 /y | μ m/y | g/m2/y | um/y | g/m2/y | um/y | |||||

| Tough Marine Climate | 140 | 9.8 | tough Marine Climate | 140 | 9.8 | 16 | 2.2 | |||

| Moderate Marine Climate | 18 | 1.3 | Modeerate Marine Climate | 18 | 1.3 | 4 | 0.54 | |||

| Industrial Climate | 20 | 1.4 | Industrial Climate | 20 | 1.4 | 4.2 | 0.57 | |||

| Countryside Climate | 4 | 0.28 | Countryside Climate | 4 | 0.28 | 1.3 | 0.17 | |||

| Plainness of hot dip galvanized substrate A.2.1 For steel sheet with a specified minimum yield strength less than 260MPa, the maximum plainness tolerance should be in conformity with the stipulations of Table A1. | ||||||||||

| MPa | Nominal width | Plainness (mm) for the nominal thickness as shown below | ||||||||

| Common precise PF.A | High-level precision PF.B | |||||||||

| <0.70 | 0.70~<1.60 | 1.60~3.0 | <0.70 | 0.70~<1.60 | 1.60~3.0 | |||||

| <260 | <1200 | 10 | 8 | 8 | 5 | 4 | 3 | |||

| 1200~<1500 | 12 | 10 | 10 | 6 | 5 | 4 | ||||

| ≥1500 | 17 | 15 | 15 | 8 | 7 | 6 | ||||

| For steel sheet and steel strip with a specified minimum yield strength not less than 260MPa but less than 360MPa,and the grades of DC51+Z/Z DD51D+Z /S550GD+Z/ZF), the maximum plainness tolerance should be in conformity with the stipulations of Table A2. Table A2 | ||||||||||

| MPa | Nominal width | Plainness (mm) for the nominal thickness as shown below | ||||||||

| Common precise PF.A | High-level precision PF.B | |||||||||

| <0.70 | 0.70~<1.60 | 1.60~3.0 | <0.70 | 0.70~<1.60 | 1.60~3.0 | |||||

| 260~<360 | <1200 | 13 | 10 | 10 | 8 | 6 | 5 | |||

| 1200~<1500 | 15 | 13 | 13 | 9 | 8 | 6 | ||||

| ≥1500 | 20 | 19 | 19 | 12 | 10 | 9 | ||||

| Thickness tolerance for hot dip galvanized substrate | ||||||||||

| For steel sheet with a specified minimum yield strength less than 260MPa, the maximum thickness tolerance should be in conformity with the stipulations of Table A6. | ||||||||||

| Nominal thickness | Thickness tolerance while the widths are showed as follows | |||||||||

| Common precise PT.A | High-level precision PT.B | |||||||||

| ≤1200 | >1200~1500 | >1500 | ≤1200 | >1200~1500 | >1500 | |||||

| 0.30~0.40 | ±0.04 | ±0.05 | ±0.06 | ±0.030 | ±0.035 | ±0.040 | ||||

| >0.40~0.60 | ±0.04 | ±0.05 | ±0.06 | ±0.035 | ±0.040 | ±0.045 | ||||

| >0.60~0.80 | ±0.05 | ±0.06 | ±0.07 | ±0.040 | ±0.045 | ±0.050 | ||||

| >0.80~1.00 | ±0.06 | ±0.07 | ±0.08 | ±0.045 | ±0.050 | ±0.060 | ||||

| >1.00~1.20 | ±0.07 | ±0.08 | ±0.09 | ±0.050 | ±0.060 | ±0.070 | ||||

| >1.20~1.60 | ±0.10 | ±0.11 | ±0.12 | ±0.060 | ±0.070 | ±0.080 | ||||

| >1.60~2.00 | ±0.12 | ±0.13 | ±0.14 | ±0.070 | ±0.080 | ±0.090 | ||||

| >2.00~2.50 | ±0.14 | ±0.15 | ±0.16 | ±0.090 | ±0.100 | ±0.110 | ||||

| >2.50~3.00 | ±0.17 | ±0.17 | ±0.18 | ±0.110 | ±0.120 | ±0.130 | ||||

| For steel sheet and steel strip with a specified minimum yield strength not less than 260MPa but less than 360MPa, the thickness tolerance should be in conformity with the stipulations of Table A7. | ||||||||||

| Nominal thickness | Thickness tolerance while the widths are showed as follows | |||||||||

| Common precise PT.A | High-level precision PT.B | |||||||||

| ≤1200 | >1200~1500 | >1500 | ≤1200 | >1200~1500 | >1500 | |||||

| 0.30~0.40 | ±0.05 | ±0.06 | ±0.07 | ±0.035 | ±0.040 | ±0.045 | ||||

| >0.40~0.60 | ±0.05 | ±0.06 | ±0.07 | ±0.040 | ±0.045 | ±0.050 | ||||

| >0.60~0.80 | ±0.06 | ±0.07 | ±0.08 | ±0.045 | ±0.050 | ±0.060 | ||||

| >0.80~1.00 | ±0.07 | ±0.08 | ±0.09 | ±0.050 | ±0.060 | ±0.070 | ||||

| >1.00~1.20 | ±0.08 | ±0.09 | ±0.11 | ±0.060 | ±0.070 | ±0.080 | ||||

| >1.20~1.60 | ±0.11 | ±0.13 | ±0.14 | ±0.070 | ±0.080 | ±0.090 | ||||

| >1.60~2.00 | ±0.14 | ±0.15 | ±0.16 | ±0.080 | ±0.090 | ±0.110 | ||||

| >2.00~2.50 | ±0.16 | ±0.17 | ±0.18 | ±0.110 | ±0.120 | ±0.130 | ||||

| >2.50~3.00 | ±0.19 | ±0.20 | ±0.20 | ±0.130 | ±0.140 | ±0.150 | ||||

| For steel sheet and steel strip with a specified minimum yield strength not less than 360MPa, but less than or equal to 420 MPa, the thickness tolerance should be in conformity with the stipulations of Table A8. | ||||||||||

| Nominal thickness | Thickness tolerance while the widths are showed as follows | |||||||||

| Common precise PT.A | High-level precision PT.B | |||||||||

| ≤1200 | >1200~1500 | >1500 | ≤1200 | >1200~1500 | >1500 | |||||

| 0.30~0.40 | ±0.05 | ±0.06 | ±0.07 | ±0.040 | ±0.045 | ±0.050 | ||||

| >0.40~0.60 | ±0.06 | ±0.07 | ±0.08 | ±0.045 | ±0.050 | ±0.060 | ||||

| >0.60~0.80 | ±0.07 | ±0.08 | ±0.09 | ±0.050 | ±0.060 | ±0.070 | ||||

| >0.80~1.00 | ±0.08 | ±0.09 | ±0.11 | ±0.060 | ±0.070 | ±0.080 | ||||

| >1.00~1.20 | ±0.10 | ±0.11 | ±0.12 | ±0.070 | ±0.080 | ±0.090 | ||||

| >1.20~1.60 | ±0.13 | ±0.14 | ±0.16 | ±0.080 | ±0.090 | ±0.110 | ||||

| >1.60~2.00 | ±0.16 | ±0.17 | ±0.19 | ±0.090 | ±0.110 | ±0.120 | ||||

| >2.00~2.50 | ±0.18 | ±0.20 | ±0.21 | ±0.120 | ±0.130 | ±0.140 | ||||

| >2.50~3.00 | ±0.22 | ±0.22 | ±0.23 | ±0.140 | ±0.150 | ±0.160 | ||||

| For steel sheet and steel strip with a specified minimum yield strength not less than 420MPa, but less than or equal to 900 MPa, the thickness tolerance should be in conformity with the stipulations of Table A9. | ||||||||||

| Nominal thickness | Thickness tolerance while the widths are showed as follows | |||||||||

| Common precise PT.A | High-level precision PT.B | |||||||||

| ≤1200 | >1200~1500 | >1500 | ≤1200 | >1200~1500 | >1500 | |||||

| 0.30~0.40 | ±0.06 | ±0.07 | ±0.08 | ±0.045 | ±0.050 | ±0.060 | ||||

| >0.40~0.60 | ±0.06 | ±0.08 | ±0.09 | ±0.050 | ±0.060 | ±0.070 | ||||

| >0.60~0.80 | ±0.07 | ±0.09 | ±0.11 | ±0.060 | ±0.070 | ±0.080 | ||||

| >0.80~1.00 | ±0.09 | ±0.11 | ±0.12 | ±0.070 | ±0.080 | ±0.090 | ||||

| >1.00~1.20 | ±0.11 | ±0.13 | ±0.14 | ±0.080 | ±0.090 | ±0.110 | ||||

| >1.20~1.60 | ±0.15 | ±0.16 | ±0.18 | ±0.090 | ±0.110 | ±0.120 | ||||

| >1.60~2.00 | ±0.18 | ±0.19 | ±0.21 | ±0.110 | ±0.120 | ±0.140 | ||||

| >2.00~2.50 | ±0.21 | ±0.22 | ±0.24 | ±0.140 | ±0.150 | ±0.170 | ||||

| >2.50~3.00 | ±0.24 | ±0.25 | ±0.26 | ±0.170 | ±0.180 | ±0.190 | ||||

| Width tolerance | ||||||||||

| Nominal width | Width tolerance | Width tolerance of the hot-dip zinc, hot-dip alu-zinc coated alloy steel sheets should conform to relevant parameters designed by A12. | ||||||||

| Common precise PW.A | High-level precision PW.B | |||||||||

| ≤1200 | 0~+5 | 0~+2 | ||||||||

| >1200~1500 | 0~+6 | 0~+2 | ||||||||

| >1500 | 0~+7 | 0~+3 | ||||||||

- Q: I'm writing a story, and trying to find out how hot it needs to be for steel to turn into a gas.

- Steel is to broad. There are many types of steel with different melting/boiling points. Iron* has a boiling point of 5182 °F and a Heat of vaporization of 340 kJ·mol?1. iron is the main ingredient of steel, along with carbon and other various elements.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: What are the different coil coating options available for steel coils?

- Steel coils have several coil coating options available, each with its own unique benefits and applications. 1. The affordability and versatility of polyester coil coatings make them the most commonly used option. These coatings offer good durability, weather resistance, and color retention, making them suitable for a wide range of indoor and outdoor uses. 2. PVDF coil coatings provide excellent resistance to fading, chalking, and chemical exposure. They are highly durable, making them ideal for exterior applications that require long-term performance. PVDF coatings also have good dirt and stain resistance. 3. Polyurethane coil coatings offer exceptional adhesion and flexibility. They are often used in applications that require excellent resistance to abrasion, impact, and corrosion. Polyurethane coatings also provide good color retention and weather resistance. 4. SMP coatings combine the benefits of polyester and silicone coatings. They offer enhanced resistance to chalking, fading, and industrial pollutants. SMP coatings are commonly used in agricultural, industrial, and architectural applications. 5. PVC coil coatings provide excellent chemical resistance and are frequently used in applications where resistance to acids, alkalis, and solvents is crucial. These coatings also offer good color retention and have a low environmental impact. 6. Epoxy coatings provide exceptional adhesion and corrosion resistance. They are often used in demanding environments such as the marine or chemical processing industries. Epoxy coatings can be customized to meet specific performance requirements. 7. Acrylic coatings offer excellent color retention, UV resistance, and gloss retention. They are commonly used in architectural applications where aesthetics are important. Acrylic coatings also provide good resistance to weathering and chemicals. When choosing a coil coating option, it is important to consider the specific requirements of the application. Factors such as durability, weather resistance, chemical resistance, adhesion, and color retention should be taken into account to ensure the best performance and longevity of the steel coils.

- Q: A friends of mine says he has balls of steel and i told him i would melt em off with lava. He said it wouldnt work. i disagree

- Standard steel melts around 1400-1500 C. Erupting lava can be as hot as 1600 C. There are various types of steel with different melting points though, and the temperature of lava varies widely, so your question can't really be answered definitively. Some lava is definitely hot enough to melt steel though, so you are right and your friend is wrong. :)

- Q: What are the different types of steel coil coatings for heat resistance?

- There are several different types of steel coil coatings that provide heat resistance, including silicone-modified polyester (SMP), polyvinylidene fluoride (PVDF), and high-temperature silicone.

- Q: I worked REALLY HARD basically begged my dad to let me stretch my ear lobe piercings. He finally said yes, as long as I don't pass 2g. c: So, we went to Hot Topic to buy tapers, but I don't know if I should get Steel or Acrylic tapers. Which ones are better to start off with?

- Steel, and stainless/surgical steel at that. If not, titanium. Especially for new stretching, you don't wnat any metal in there that you may have a reaction to.

- Q: How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as the primary material for manufacturing the latch components. These coils are processed through various stages like cutting, shaping, and forming to create the desired latch design. The steel coils provide the necessary strength and durability required for the latch to function effectively and securely.

- Q: Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- Sorry okorder /... I hope that link works but as you can see you dont want to use 303.304.316,410,416,430 You can get away with 301 but would be best to use 440. It kind of sounds like your a home shop guy. It would be best for you to make a knife out of a1 or d2 tool steel. with these steels you can torch heat them to a red hot heat where a magnet will not stick to them. Then let them cool slowly in the air. After that you can temper in a oven around 400f. This will a very hard long lasting knife. Check OKorder for good steel prices. A1 and D2 are not stainless but they are the best for a home shop. If you go stainless you can buy preharden material but you will have to grind everything. You can also pay someone to harden your knife but dont plan on it being cheap.

- Q: What are the different methods of slitting edge trimming for steel coils?

- There are several different methods of slitting edge trimming for steel coils, each with its own advantages and applications. 1. Rotary Shear Slitting: This method involves using rotary knives to cut through the steel coil. The knives are mounted on a rotating shaft and create a shearing action as they pass through the coil. Rotary shear slitting is a versatile method that can handle a wide range of coil thicknesses and materials. It is commonly used for high-volume production and provides a clean and precise cut. 2. Crush Cut Slitting: In this method, the steel coil is pressed against a hardened anvil by a rotating knife. The knife cuts through the coil by crushing it against the anvil. Crush cut slitting is suitable for thinner gauge materials and is often used for materials that are sensitive to shearing forces. It provides a clean cut but may have limitations in terms of coil thickness and width. 3. Razor Slitting: Razor slitting involves using a razor blade to cut through the steel coil. The blade is mounted on a rotating shaft and creates a slicing action as it passes through the coil. Razor slitting is commonly used for thin and delicate materials that require a precise and burr-free edge. It provides a clean cut but may have limitations in terms of coil thickness and width. 4. Shear Slitting: This method involves using a pair of opposing blades to shear through the steel coil. The blades move past each other to create a scissor-like cutting action. Shear slitting is commonly used for heavier gauge materials and provides a clean and precise cut. It is suitable for high-speed production and can handle a wide range of coil thicknesses and materials. 5. Laser Slitting: Laser slitting utilizes a high-powered laser beam to cut through the steel coil. The laser beam is guided by computer-controlled optics to create a precise and clean cut. Laser slitting is suitable for a wide range of coil thicknesses and materials, including high-strength steels. It provides a high level of accuracy and can handle complex cutting patterns. Each of these methods has its own advantages and considerations, depending on the specific requirements of the steel coil slitting operation. Factors such as coil thickness, material type, desired edge quality, and production volume will influence the choice of slitting method.

- Q: What are the environmental and social impacts of mining, processing and using steel?

- Without it, you would not have many of the things that you enjoy today. Just think, no cannons, unless they were made of bronze, but that requires mining as well. No computers, no cars, no skate boards, no tall buildings, no pots and pans, no bath tubs, no factories to build things that are made out of non-metallic materials. No stereos, no TVs, no eating utensils, just think, you would have to eat like the Japanese do with bowls and your fingers. In short, just about everything around you is some how made with steel. If you are against steel and feel that it's impact on the ecology of the world is to great, what would you be willing to give up? Your car, ipod, computer, stereo, bed-everything about it uses steel in 0one way or another. Your Cd's, DVDs, just what would you want to give up because, yuck, it was made with steel equipment, or to some extent, made from steel.

Send your message to us

Color coated Galvanized Cold rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords