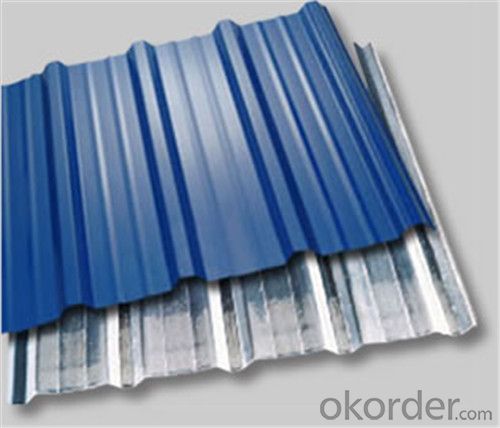

Color Coated galvanized cold Rolled Steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SIZE:

Thickness: 0.12-1.5mm

Width: 600mm,750mm,762mm,900mm,914mm,940mm,1000mm,1050mm, 1090mm,1100mm,1200mm, 1219mm, 1250mm,1250mm

Length: According to the customer's request

Hardness:Soft( around HRB 65) ,full hard (HRB90-95)

Strength of Extension: more than 300Mpa

Yield Strength:370-380Mpa

Thickness tolerance: +/-0.02 mm(0.01 as you requested)

Width tolerance:+/ -2.0mm

ZINC, PAINT & COLOR:

Zinc coating: 30-275G/M2

Paint thickness: Top 15-25um + Back 8-10um

Paint: Epoxy Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester

Color: As the RAL color standard or customer's sample

| Base mental | hot galvanized /galvalume steel coil |

| Thickness | 0.12-1.5mm |

| Width | 600-1500mm |

| Coil Weight | 3-5ton |

| Quality: | DX51D DQ CQ |

| Color | all RAL colors or as per customers' sample |

| Zinc-coating | 30g/m2-275g/m2 |

| Coil ID | 508mm-610mm |

| Packing | standard seaworthy package |

| Technique | cold rolled, hot-dipped galvanizing, color coated |

| Painting | Top and bottom: 20mic+5mic RMP Back: 8mic-10mic |

| Tolerance | Thickness: +/-0.02mm Width: +/-2mm |

| Description | Pre-painted Steel Coil uses hot galvanized steel as its basic material, factory adopts advanced equipment to degrease, rinse, transform the galvanized steel, then make primary and refined lavation to the steel coils. |

| application | They are mainly applied for steel structure buildings, household appliance, furniture, transportation and other industries |

| feature | Pre-painted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

| The special order can be negotiated | |

- Q: How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength, flexibility, and energy dissipation. When steel coils are incorporated into the structure's design, they act as seismic dampers, absorbing and dissipating the energy generated during an earthquake. The coils help to distribute and reduce the seismic forces, minimizing structural damage and enhancing the overall stability and resilience of the building. Additionally, the flexibility of steel coils allows them to withstand forces without breaking, ensuring the structure's integrity and safety during seismic events.

- Q: rust is not a issue. i was looking a D2 steel but heard story's of it chipping and breaking

- INFI steel used by Busse Combat is probably one of the best steels around right now, but the price reflects that. The heat treat is a HUGE part of the toughness of a steel. A good heat treat can make a bad steel a good one, or a good one a great one. I personally prefer 1095. It's a good ole tool steel on the lower end of the price scale and it holds up well. I've always had good experiences with 1095.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps to ensure their quality and suitability for various applications. The process begins with uncoiling the steel coil, which involves removing the outer layers of protective wrapping and unwinding the coil. Once uncoiled, the steel is inspected for any defects, such as cracks or uneven surfaces. Next, the steel coil goes through a cleaning process to remove any dirt, oil, or rust present on its surface. This is typically done using a combination of chemical cleaning agents and mechanical scrubbing. After cleaning, the coil is rinsed and dried to prevent any residual moisture from causing corrosion. Once cleaned, the steel coil can undergo various treatments depending on its intended use. One common treatment is pickling, which involves immersing the coil in an acidic solution to remove impurities and scale. This process helps to improve the surface finish and prepares the steel for further processing. After pickling, the coil may be subjected to cold rolling, a process that reduces its thickness and improves its dimensional accuracy. Cold rolling involves passing the steel through a series of rollers at room temperature, gradually reducing its thickness and increasing its strength. This process also improves the surface finish of the steel coil. In some cases, the steel coil may undergo additional heat treatment processes, such as annealing or tempering. Annealing involves heating the coil to a specific temperature and then slowly cooling it, which helps to relieve internal stresses and improve its mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and then cooling it rapidly. This process enhances the strength and toughness of the steel. Once the desired processing and treatments are complete, the steel coil may be coated or painted to provide additional protection against corrosion or to enhance its aesthetic appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings such as paint or powder coatings. Finally, the processed and treated steel coils are typically cut into specific sizes or shapes based on customer requirements. This can be done using various cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve a combination of cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- okorder can give you helps.

- Q: How are steel coils packaged for shipment?

- Steel coils are typically packaged for shipment by being tightly wrapped in protective materials such as plastic or steel strapping. They are then secured onto pallets or placed into steel crates, ensuring stability during transportation. The packaging helps to prevent damage, corrosion, and movement during handling and transit.

- Q: Steel Strings on your guitar or nylons? Why?

- Kind of a silly question. I use steel strings on my steel string guitars and nylon strings on my classical guitar. It's not something you have any choice in; steel string guitars must use steel strings and classical guitar must use nylon strings.

- Q: the difference between the original steel and mild steel from percentage of carbon

- As the first answers suggest, the prolbem is that these terms are not specific, they are not scientifically or technically defined. This is like asking: what is the difference between a four door car and a sedan? There are hundreds of steel alloys ranging from Fe + a little C + very little else to alloy and tool steels with significant amounts of Cr, Ni, Si, and a number of other elements + C. And... for any given steel alloy, there are many different ways to heat treat it. A given piece of steel can be heat treated so hard and brittle that it could shatter like glass and then it could be heat treated to make it into a spring or heat treated to make it stretch like taffy. If you really want to understand steels, yes, there are lots of books on sword making (some written by people who actually understand steels) but... you need to study metallurgy. There are graduate level courses just on the metallurgy of steels. Of course to understand this course you need to understand a whole lot of fundamental metallurgy. All this stuff on steel makes perfect sense because, in terms of weight (tonage) produced, steel is, hands down, nothing else remotely comes close, the most important metal humans have.

- Q: Can steel coils be coated with impact-resistant materials?

- Yes, steel coils can be coated with impact-resistant materials. The coating process involves applying a layer of impact-resistant material onto the surface of the steel coils to enhance their durability and protection against impacts or damages. This coating can provide additional strength and resistance, making the coils suitable for various applications requiring impact resistance.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they are formed into specific shapes and sizes to create the necessary components, such as pipes, mufflers, and catalytic converters. The coils are precision-cut, welded, and bent to fit the design requirements and ensure efficient exhaust flow, durability, and resistance to high temperatures and corrosion.

- Q: Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Stainless steel is an alloy of iron and other metals, notably Chromium and vanadium. You do not see it with the naked eye but at the surface of any stainless steel (SS) there are iron atoms and chromium atoms that are exposed. However, the chromium reacts preferentially to form an oxide. In essence, think of chromium sacrificing itself for iron so that iron will not rust. What a nice guy huh! This is called passivation just like most responders said. However, more than that the chromium oxide forms a tight protective layer that forms a physical barrier preventing Oxygen or any oxidant to reach and attack the iron underneath it. Also, the chromium oxide formed is not FLAKY and porous, so it does not mar much of the surface as an iron oxide (rust) would. For science project, you may not make it too technical but you can make a reference or make an ANALOGY of rust prevention to high school or social situations as being there for your friend or classmate But in real life, when the odds are too great, that protection afforded by chromium may not be enough. Because eventually all steel exposed to very oxidizing atmospheres will rust. Just a little break in the surface is enough to start the process of rusting.

Send your message to us

Color Coated galvanized cold Rolled Steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords