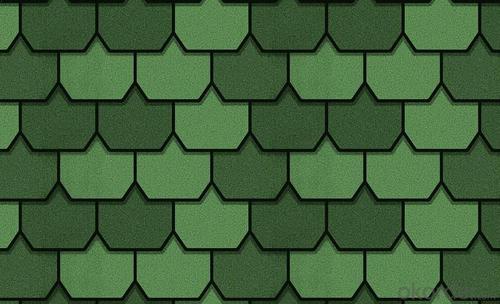

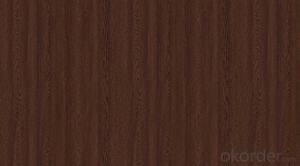

color bond surface coating steel plate--XY021

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Color bond surface coating steel plate :

2.More than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

4.If you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

5.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: Can steel sheets be used for heat transfer applications?

- Yes, steel sheets can be used for heat transfer applications. Steel is a good conductor of heat, which means it can efficiently transfer heat from one surface to another. Steel sheets are often used in various heat transfer applications, such as heat exchangers, HVAC systems, and industrial machinery. They are known for their high thermal conductivity and durability, making them suitable for transferring heat in a wide range of industries and applications. Additionally, steel sheets can be easily fabricated and formed into different shapes and sizes, allowing for customized heat transfer solutions.

- Q: Can the steel sheets be easily engraved or etched?

- Yes, steel sheets can be easily engraved or etched. Engraving or etching on steel sheets is a common practice in various industries, such as automotive, aerospace, and jewelry. This process involves using specialized tools and techniques to create intricate designs, patterns, or text on the surface of the steel sheets. The hardness and durability of steel make it suitable for engraving, as it can withstand the pressure and cutting force required to create detailed engravings. Additionally, the smooth surface of steel sheets ensures precise and clear etching results. However, it is important to note that the ease of engraving or etching may vary depending on the type and grade of steel being used.

- Q: Are the steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications. Steel is known for its excellent strength and durability, making it a popular choice for various industries requiring materials that can withstand high temperatures. Steel sheets can be manufactured to have high melting points and can retain their structural integrity even under extreme heat. Additionally, steel has good thermal conductivity, allowing it to efficiently transfer heat away from the surface. However, it is important to consider the specific grade and composition of the steel sheets as some alloys are specifically designed for high-temperature applications. It is recommended to consult with a materials engineer or specialist to ensure that the steel sheets selected are suitable for the specific high-temperature environment.

- Q: Can steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets. Steel is a strong and durable material that provides excellent structural support, making it ideal for storing heavy items. It also offers resistance to corrosion, making it suitable for long-term storage.

- Q: What is the average cost of installing steel sheets?

- The cost of installing steel sheets can differ depending on several factors, including project size, steel sheet type and quality, location, and labor expenses. On average, the installation cost varies between $7 and $15 per square foot. Nevertheless, it is crucial to acknowledge that this is merely a general approximation, and actual expenses might differ significantly. It is advisable to obtain quotations from multiple contractors or steel suppliers to acquire a more precise estimate tailored to a specific project.

- Q: What is the average lifespan of painted steel sheets?

- Painted steel sheets can have varying lifespans depending on factors such as paint quality, usage environment, and maintenance levels. Generally, their lifespan ranges from 15 to 25 years. This estimate is based on proper installation, regular inspections for damage or corrosion, and necessary touch-up or maintenance work. It is worth noting that exposure to severe weather, chemicals, and physical damage can significantly affect the lifespan of painted steel sheets. To go beyond the average range, regular maintenance and appropriate care are essential.

- Q: What industries commonly use steel sheets?

- The industries that commonly use steel sheets include construction, automotive, manufacturing, aerospace, and shipbuilding.

- Q: Can steel sheets be used in the construction industry?

- Yes, steel sheets can be commonly used in the construction industry. Steel sheets are highly versatile and have a wide range of applications in construction. They are used for various purposes, including roofing, wall cladding, flooring, and structural components such as beams, columns, and trusses. Steel sheets are preferred due to their high strength-to-weight ratio, durability, and resistance to corrosion. They can withstand heavy loads and provide stability and structural integrity to buildings. Additionally, steel sheets can be easily fabricated, allowing for customization and efficient construction processes. Overall, steel sheets are a popular choice in the construction industry due to their numerous advantages and suitability for various construction applications.

- Q: What is the difference between a hot rolled and cold rolled stainless steel sheet?

- The main difference between a hot rolled and cold rolled stainless steel sheet lies in the production process. Hot rolled stainless steel sheets are made by heating a stainless steel slab above its recrystallization temperature and then rolling it through a series of rollers until the desired thickness is achieved. This process results in a rough, scaled surface with a characteristic oxide layer. On the other hand, cold rolled stainless steel sheets are produced by further processing the hot rolled sheets. The hot rolled sheets are first annealed, which involves heating them and then cooling them slowly to regulate the microstructure and remove any stresses. After annealing, the sheets are cold rolled, which means they are passed through a set of rollers at room temperature to achieve the desired thickness. This process results in a smoother, more refined surface with improved mechanical properties. In summary, hot rolled stainless steel sheets have a rough surface and are less precise in terms of thickness, while cold rolled stainless steel sheets have a smoother surface and are more precise in terms of thickness. Cold rolled sheets also tend to have better mechanical properties due to the additional processing steps involved.

- Q: Can the steel sheets be used for automotive body panels?

- Indeed, automotive body panels can utilize steel sheets. The automotive industry often opts for steel as a material of choice owing to its robustness, resilience, and capacity to withstand impacts. Body panels frequently employ steel sheets because they confer structural integrity to vehicles and effectively safeguard occupants during collisions. Furthermore, steel can be effortlessly shaped and molded into intricate forms, rendering it ideal for designing diverse body panels. All in all, steel sheets are a dependable and frequently preferred option for automotive body panels.

Send your message to us

color bond surface coating steel plate--XY021

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords