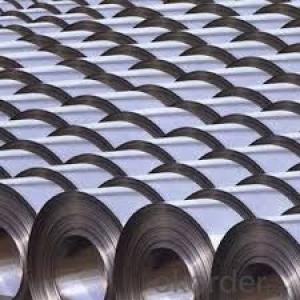

color bond surface coating steel plate--XY015

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Color bond surface coating steel plate :

2.More than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

4 If you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

5.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: What is the typical cost of steel sheets compared to aluminum?

- The typical cost of steel sheets is generally lower compared to aluminum. Steel is one of the most widely used materials in construction and manufacturing due to its strength, durability, and affordability. Steel sheets are produced in large quantities and are readily available in various grades and thicknesses, making them more cost-effective. On the other hand, aluminum is a lightweight and corrosion-resistant metal, which makes it desirable for certain applications such as aerospace or automotive industries. However, aluminum is more expensive to produce and process compared to steel, resulting in higher costs for aluminum sheets. Ultimately, the cost difference between steel and aluminum sheets will depend on factors such as market demand, current metal prices, and specific requirements of the project or application.

- Q: Can steel sheets be used for heat transfer applications?

- Yes, steel sheets can be used for heat transfer applications due to their high thermal conductivity and ability to withstand high temperatures. They are commonly used in various industries, such as HVAC systems, automotive manufacturing, and power generation, for efficient heat transfer and dissipation.

- Q: Are steel sheets resistant to vibrations?

- Yes, steel sheets are generally resistant to vibrations due to their high strength and stiffness, which helps absorb and dampen vibrations effectively.

- Q: What are the common sizes of steel sheets available in the market?

- The common sizes of steel sheets available in the market vary, but some of the standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are commonly used in construction, manufacturing, and various industrial applications.

- Q: Can the steel sheets be easily welded?

- Steel sheets can indeed be welded with ease. Joining steel sheets together is commonly achieved through the process of welding. This procedure entails melting the edges of the steel sheets, followed by allowing them to cool and solidify, resulting in a sturdy connection. It is worth mentioning, however, that the ease of welding may vary depending on factors such as the type and thickness of the steel sheets, as well as the expertise and experience of the welder. Furthermore, it is crucial to adhere to appropriate safety measures and welding techniques to guarantee a successful and secure welding procedure.

- Q: Are steel sheets suitable for bulletproof applications?

- Yes, steel sheets are commonly used in bulletproof applications due to their high strength and durability. They provide excellent protection against bullets, making them suitable for various bulletproof applications such as armored vehicles, body armor, and bulletproof barriers.

- Q: Can steel sheets be painted after installation?

- After the installation, it is possible to paint steel sheets for aesthetic improvement and protection against rust and corrosion. However, before applying paint, it is crucial to ensure that the surface is clean and devoid of any pollutants. Adequate preparation, such as cleaning and sanding, is necessary to promote adhesion and achieve a durable finish. It is advisable to use a primer specifically formulated for steel surfaces before applying the desired paint color. Moreover, selecting a high-quality paint suitable for exterior or industrial use will yield optimal results and longevity.

- Q: Can steel sheets be used in corrosive chemical environments?

- In corrosive chemical environments, the use of steel sheets is possible, but it is crucial to consider the specific type of steel and its resistance to corrosion. Stainless steel, for instance, is widely employed in such environments due to its excellent corrosion resistance properties. It contains a minimum of 10.5% chromium, which creates a protective oxide layer on the steel's surface, preventing further corrosion. Consequently, stainless steel sheets are suitable for a diverse range of corrosive chemical environments, including those involving acids, alkalis, and salts. However, it is vital to select the appropriate grade of stainless steel that matches the specific corrosive chemicals present in the environment. Furthermore, applying protective coatings or surface treatments can further enhance the corrosion resistance of steel sheets in harsh chemical environments. Seeking advice from corrosion experts or engineers is essential in determining the most suitable steel grade and protective measures for a particular corrosive chemical environment.

- Q: How do steel sheets perform in low-temperature environments?

- Steel sheets perform well in low-temperature environments due to their exceptional strength, durability, and resistance to fracture. Unlike other materials, steel retains its mechanical properties even at extremely low temperatures, making it a reliable choice for various applications in cold climates or industries like construction, transportation, and energy.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide strong support and durability, making them an ideal choice for securely mounting solar panels on various surfaces.

Send your message to us

color bond surface coating steel plate--XY015

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords