color bond surface coating steel plate--XY007

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Color bond surface coating steel plate :

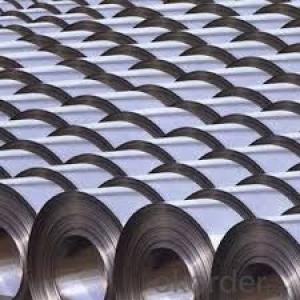

2.more than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )

zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world if you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

4.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: What is the difference between a hot rolled and hot dipped galvanized steel sheet?

- A hot rolled steel sheet is produced by rolling the steel at high temperatures, typically above 1,000 degrees Fahrenheit. This process allows the steel to be shaped and formed easily, resulting in a sheet with a rougher and less precise surface finish. Hot rolled steel sheets are commonly used in applications where strength and durability are key factors, such as in construction and structural projects. On the other hand, a hot dipped galvanized steel sheet goes through an additional process after being hot rolled. The steel sheet is immersed in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating provides excellent corrosion resistance and helps to prevent rusting, making hot dipped galvanized steel sheets ideal for outdoor and exposed applications. The main difference between the two types of steel sheets lies in their surface finish and protective properties. While hot rolled steel sheets have a rougher surface, hot dipped galvanized steel sheets have a smoother and more uniform appearance due to the zinc coating. Additionally, the galvanization process provides enhanced corrosion protection to the steel, extending its lifespan and making it suitable for harsh environments. In summary, hot rolled steel sheets are versatile and commonly used in various applications, while hot dipped galvanized steel sheets offer added protection against corrosion and are often preferred for outdoor or exposed applications.

- Q: Can steel sheets be used for signage purposes?

- Yes, steel sheets can be used for signage purposes. Steel sheets are durable and can withstand harsh weather conditions, making them suitable for outdoor signage. They can be cut, shaped, and welded into various sizes and designs, providing flexibility in creating custom signage. Steel sheets can also be painted or coated with different finishes to enhance aesthetics and ensure longevity. Additionally, steel sheets are sturdy and can be mounted securely, making them ideal for large and heavy signage installations.

- Q: What are the different sheet metal folding techniques for steel sheets?

- Steel sheets can be subjected to various sheet metal folding techniques. These techniques find extensive application in industries like automotive, aerospace, and construction for creating intricate shapes and structures. Some frequently used sheet metal folding techniques for steel sheets comprise: 1. Box and Pan Folding: This technique entails bending the sheet metal along multiple parallel edges to form a box-shaped structure. It is commonly utilized for manufacturing enclosures, cabinets, and trays. 2. Hemming: Hemming is employed to fold the edges of a sheet metal component, enhancing its rigidity and eliminating sharp edges. It finds prominent usage in the automotive sector for fabricating panels and body parts. 3. Brake Press Folding: Brake press, a machine tool utilizing hydraulic or mechanical press, is employed to bend the sheet metal. Precise and accurate folding is facilitated by adjusting the bend's angle and depth. Brake press folding is a frequently employed technique in sheet metal fabrication. 4. Roll Forming: Roll forming is a continuous bending process wherein the sheet metal passes through a series of rollers, gradually shaping it into the desired profile. It is suitable for creating elongated and continuous shapes like tubes and channels. 5. Rotary Folding: In this technique, a rotating tool is utilized to fold the sheet metal along a curved or circular path. It is often applied to create rounded edges, curves, and cylindrical shapes. 6. Folding Machines: Folding machines are specifically designed to fold sheet metal by applying pressure along a predetermined line. These machines can be programmed to carry out various folding operations, including simple bends, complex shapes, and multiple folds. Each of these sheet metal folding techniques possesses its own advantages and limitations. The selection of a particular technique depends on factors such as the design's complexity, required precision, and production volume. Skilled craftsmen and specialized machinery are frequently employed to ensure accurate and efficient folding of steel sheets.

- Q: What are the different surface finishes for steel sheets?

- There are several different surface finishes for steel sheets, including mill finish, brushed finish, mirror finish, embossed finish, and coated finish.

- Q: Can steel sheets be used for bulletproof applications?

- Indeed, steel sheets possess the ability to serve in bulletproof capacities. Steel, renowned for its strength and durability, effectively halts bullets from breaching its surface. Industries commonly employ bulletproof steel sheets during the production of armored vehicles, military apparatus, and personal protective equipment, including bulletproof vests and helmets. The bulletproof capabilities of these steel sheets hinge significantly upon their thickness and quality. Manufacturers can tailor the design of steel sheets to withstand an array of ballistic threats, encompassing handguns to high-powered rifles. Moreover, steel's affordability and ease of production render it a favored selection for bulletproof applications across diverse sectors.

- Q: Can steel sheets be used in corrosive environments like saltwater?

- Steel sheets are capable of being used in corrosive environments, such as saltwater. However, their suitability for such conditions depends on the type of steel and the level of corrosion resistance it provides. Stainless steel, for instance, possesses a high resistance to corrosion and is commonly utilized in marine and saltwater settings. This type of steel contains chromium, which creates a protective layer on its surface, shielding it from reacting with the saltwater. Other varieties of steel, like carbon steel, may also be employed in saltwater environments, but they necessitate additional protective coatings or treatments to prevent corrosion. Ensuring the durability of steel sheets in corrosive environments like saltwater requires regular maintenance and proper care.

- Q: How do steel sheets handle thermal expansion?

- Thermal expansion is managed by steel sheets through their ability to expand and contract in response to temperature fluctuations. When steel is heated, it expands, and when it is cooled, it contracts, just like any other material. However, steel has a relatively low coefficient of thermal expansion compared to other materials, meaning it expands and contracts less for a given change in temperature. This characteristic makes steel sheets more resistant to warping or buckling caused by thermal expansion. Moreover, steel is a robust and long-lasting material, enabling it to withstand the stresses resulting from thermal expansion without significant damage. To further address the effects of thermal expansion, engineers often incorporate expansion joints into structures or employ techniques such as pre-stressing and anchoring to accommodate the expansion and prevent harm. As a result of these properties and design considerations, steel sheets are able to effectively manage thermal expansion.

- Q: How do steel sheets perform in terms of scratch resistance?

- Steel sheets generally have good scratch resistance due to their strong and durable nature. They are less susceptible to scratching compared to other materials, making them suitable for various applications where scratching is a concern. However, the scratch resistance may vary depending on the specific type and finish of the steel sheet.

- Q: Can steel sheets be used for making HVAC ducts?

- Indeed, it is possible to utilize steel sheets in the construction of HVAC ducts. Owing to its robustness, longevity, and fire-resistant attributes, steel is widely employed as a material for fabricating HVAC ductwork. To construct the ductwork, steel sheets are typically sliced, shaped, and fused together, enabling the efficient distribution of air throughout a structure. By employing steel sheets, the ducts can endure the elevated temperatures and pressures associated with HVAC systems, all while retaining their structural integrity. Furthermore, steel ducts exhibit increased resistance to harm caused by pests, moisture, and the growth of mold when compared to alternative materials. In summary, the reliability and capacity to meet the requisite performance standards make steel sheets a fitting choice for the production of HVAC ducts.

- Q: What is the difference between hot-rolled and cold-rolled steel sheets?

- The manufacturing process and resulting characteristics of steel sheets differ between hot-rolled and cold-rolled varieties. Hot-rolled steel sheets are produced by heating a large steel slab and passing it through high-temperature rollers. This allows for easy shaping and forming into various sizes and thicknesses. The elevated temperature also removes any residual stress in the steel, making it more flexible and moldable. Consequently, hot-rolled steel sheets possess a rougher surface finish and may exhibit a thin oxide layer called scale. However, they are generally less expensive and come in a wider range of sizes. In contrast, cold-rolled steel sheets are created by cooling down the hot-rolled steel and passing it through rollers at room temperature. This process not only reduces the steel's thickness but also enhances its surface finish and dimensional accuracy. Cold-rolling gives the steel sheets a smooth and shiny appearance, making them suitable for applications where aesthetics matter. Additionally, cold-rolling improves the steel's strength and hardness, making it more appropriate for high-stress uses. However, cold-rolled steel sheets are typically more costly due to the additional processing involved. In summary, hot-rolled steel sheets offer greater formability and lower cost, but have a rougher surface finish and may exhibit scale. On the other hand, cold-rolled steel sheets have superior surface finish, dimensional accuracy, and strength, but are pricier. Choosing between hot-rolled and cold-rolled steel sheets depends on the specific requirements of the application, including desired surface finish, strength, and cost considerations.

Send your message to us

color bond surface coating steel plate--XY007

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords