Cold Rolled Steel Sheets and Roofing Aluminum Sheets Wholesale from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

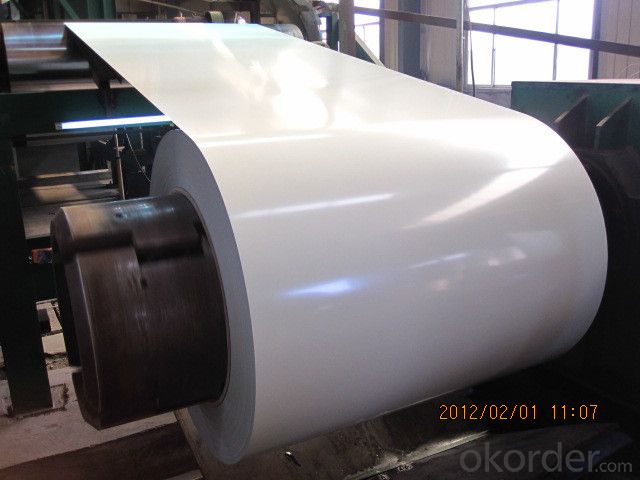

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: Is it possible to manufacture furniture using aluminum sheets?

- <p>Yes, aluminum sheets can be used to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications. It is commonly used in outdoor furniture, such as patio sets, as well as in modern indoor furniture designs. Aluminum furniture is easy to maintain, has a sleek appearance, and can be an eco-friendly choice due to its recyclability.</p>

- Q: Can aluminum sheets be used for lithographic printing?

- Indeed, lithographic printing can make use of aluminum sheets. This widely-used printing method, also referred to as offset printing, involves the transfer of an image from a plate onto a rubber blanket and subsequently onto the printing surface. Aluminum sheets are frequently employed as the foundational material for lithographic plates due to their exceptional durability, lightweight composition, and capacity to retain intricate details. Typically, these aluminum sheets utilized in lithographic printing are coated with a photosensitive emulsion, facilitating the precise and accurate transfer of the image onto the printing surface. Consequently, aluminum sheets represent an optimal selection for lithographic printing, particularly for extensive and high-quality printing endeavors.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- There are several weight-saving benefits of using aluminum sheets in different applications. Firstly, aluminum is a lightweight metal, with a density much lower than other commonly used materials such as steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in various applications. The reduced weight of aluminum sheets is particularly advantageous in transportation industries. For example, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the vehicle's overall weight. This weight reduction leads to improved fuel efficiency, as less energy is required to move the lighter vehicle. Additionally, lighter vehicles generally have better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every extra kilogram of weight on an aircraft can increase fuel consumption, and thus operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures, such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. Another industry where the weight-saving benefits of aluminum sheets are highly valued is the construction sector. Aluminum sheets are often used in the construction of buildings and infrastructure due to their lightweight nature. This lightweight characteristic not only makes installation easier but also reduces the overall load on the building's foundation. Moreover, using aluminum sheets in construction can also lead to cost savings, as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products, such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. The lightweight nature of aluminum allows for reduced weight in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets offer a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q: What is the electrical resistivity of 101 aluminum sheets?

- The electrical resistivity of 101 aluminum sheets can vary depending on the specific grade and condition of the aluminum. However, on average, aluminum has an electrical resistivity of about 2.65 x 10^-8 ohm-meters. It is important to note that this value may slightly vary due to impurities or other factors.

- Q: Can aluminum sheets be anodized with custom designs?

- Indeed, custom designs can be incorporated into aluminum sheets through anodization. Anodization, an electrochemical procedure, fortifies the inherent oxide layer on aluminum surfaces, rendering them sturdier and more resistant to corrosion. Throughout this process, diverse patterns and designs can be introduced onto the aluminum sheet by masking specific areas and exposing others to the anodizing solution. This grants the opportunity for personalized designs to be etched or dyed onto the surface, resulting in distinctive and individualized finishes. Anodized aluminum sheets with custom designs find widespread application across various industries, including architecture, automotive, and electronics, in order to fulfill both aesthetic and functional prerequisites.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet, including 3003, 5052, and 6061. Each alloy has different properties and is used for specific applications based on factors such as strength, corrosion resistance, and formability.

Send your message to us

Cold Rolled Steel Sheets and Roofing Aluminum Sheets Wholesale from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords