Stone Coated Metal Roofing Sheet from CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

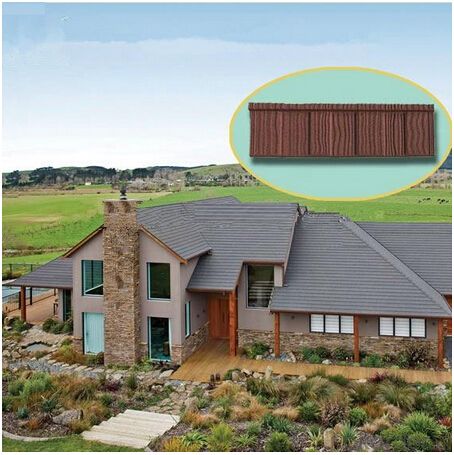

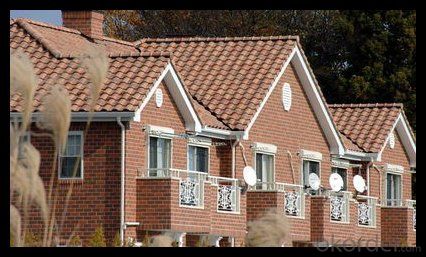

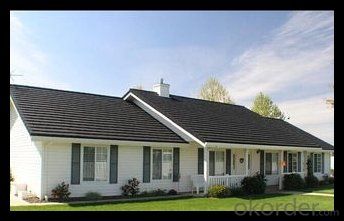

Good Roofing colorful stone coated metal roof tile, one of a series of Good Roofing tiles, is an ideal substitute for its conventional counterparts. Being not only artistic, durable, easy to install, but also eco-friendly, it has been intensively applied to residential, industrial and commercial construction, and become popular in roofing all over the world.

Product Advantages:

1. Light weight.

To compare with the traditional ceramic tile, the weight of our metal roof tile is just 1/6 of it.

It is convenient to carry, store and use, so it can save the time and cost of installation.

2. Easy installation.

Metal roof tile is very light and it is easy to incise and cut off, so it is suitable for all kinds of buildings,

especially for the heavy grade roofs and towers.

3. Excellent durability.

High quality galvalume plates and natural stone chip coatings are characterized by their excellent

anti corrosion features which extends the life span of tiles for more than 30 years without fade.

4. Recyclable and Eco-friendly.

Metal roof tiles are galvalume based and have high recyclable content. Over 90% of the tiles are

recyclable,which makes it more economical.

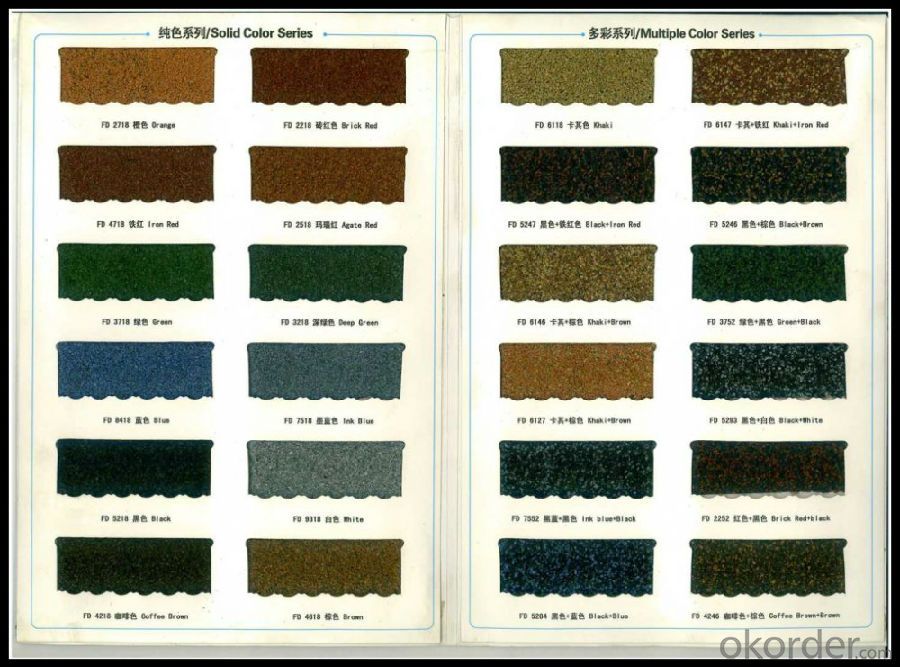

5. Beautiful appearance.

Rich color and variety types will bring a beautiful surface for your roof.

6. Earthquake resistance.

Earthquake can cause the infinite property loss, the more is because of the structure roof and the

weight of tile. Stone coated metal roof tiles are light and firm,they can lighten the building and won’t

easily cause damages to the under structures of the buildings in earthquakes.

7. Wind resistance.

Even metal tile just has the 1/6 of weight to the traditional tile,the scientific interlocking system design

techniques guarantee the roofing system more safety in the storms.

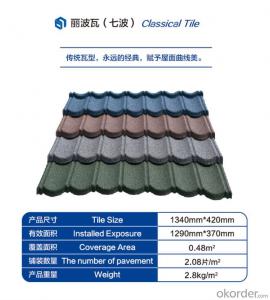

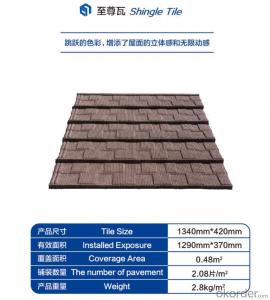

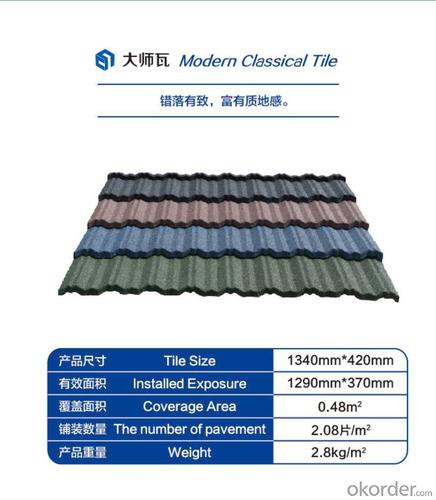

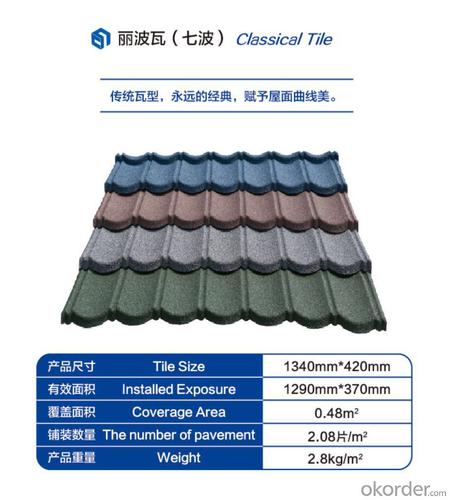

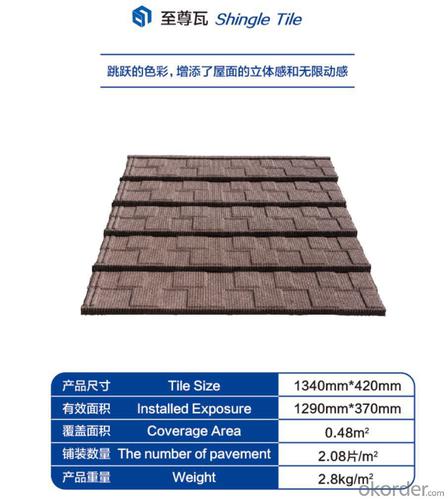

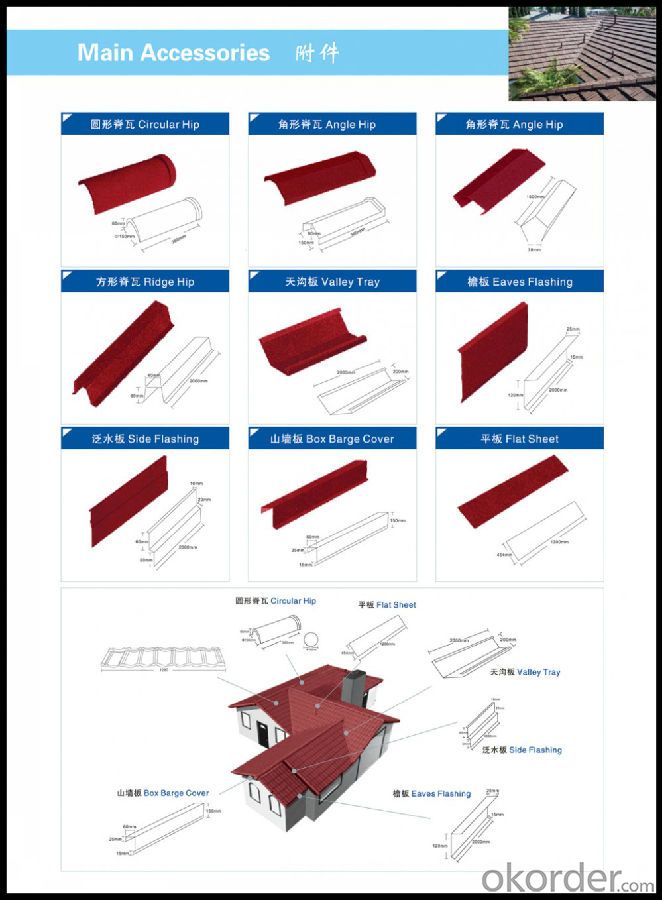

Product Specification:

| Tile Size | 1170mm*420mm |

| Installed Exposure | 1080mm*370mm |

| Coverage Area | 0.4m2 |

| The Number of Pavement | 2.5pc/m2 |

| Weight | 2.4kg/m2 |

FAQ:

Q: What's your payment?

A: T/T, L/C, etc.

Q: Can you offer samples?

A: Yes, we could offer according to customer's requirement.

Q: Can I check the quality before loading?

A: Yes, it will be better.

- Q: OKorder Xingyi where to sell auspicious aluminum-plastic plate? Used in the bathroom decoration, recommended

- You can buy in Kunming manufacturers, the price cheaper than the other side of OKorder, a home called clouds like building materials

- Q: Aluminum-plastic plate to do the first door of a square how much money a square

- According to the quality of the board, I sell aluminum-plastic plate, generally as long as no more than 80 square price in 200 or so, if the board will be a good price will be high, remember that if you use good material, must board about 150 , Otherwise the board will appear rugged, will be very ugly, if the price is too high, with 80-120 of the general material of the board, when will not be deformed, listen to me not wrong

- Q: Aluminum-plastic plate and aluminum plate which is cheap under the specific price instructions

- Qualified aluminum-plastic panels are generally in the range of 50-150 yuan per square meter. Aluminum plate is generally 80-600 yuan per square meter.

- Q: Will the aluminum plate is flammable?

- The current non-combustible grade aluminum composite panels have been mass production, according to the correct name of the core material for the aluminum composite panels,

- Q: What can aluminum-plastic plates do! Where to decorate! how to use!

- Is a smallpox material, mainly used for relatively humid place to use, buy back when he will be accompanied by some components, the installation is easy, where people will teach how to install ~ ~

- Q: 3MM aluminum composite panel prices

- According to the different thickness of aluminum, the price difference between the larger, such as the thickest can be done 0.30 mm, followed by 0.25--0.20--0.18--0.15--0.12--0.10--0.08--0.06 different thickness, Then the price range is very large. Square meter pricing, should be in the 20-120 yuan / square meters between it.

- Q: Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- It is recommended to choose a good brand of weathering sealant to fill cracks waterproof. Brand recommended options: new exhibition, white clouds, silicon treasure, the river, Dow Corning, Maxima, gold leaves and so on. The cracks appear to remove the tape, with xylene or ether scrub clean the location of the tape, and other scrubbing liquid marked with weathering sealant.

- Q: How to install Yuba on aluminum-plastic board

- Have you bought Yuba? Selling yuba will give you press ah. Or install the aluminum plate can also be installed to you.

- Q: How will aluminum-plastic plates separate aluminum and plastic? As far as possible with the machine separation, where to purchase the kind of machinery and equipment?

- So narrow corners of the human body can be stripped, the use of tensile machine stripping but not high efficiency.

- Q: Chengdu, the external walls of aluminum-plastic plate prices, labor prices, probably in the 3000 square total cost in the number

- Please ask the cost of the people to help you know it

Send your message to us

Stone Coated Metal Roofing Sheet from CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords