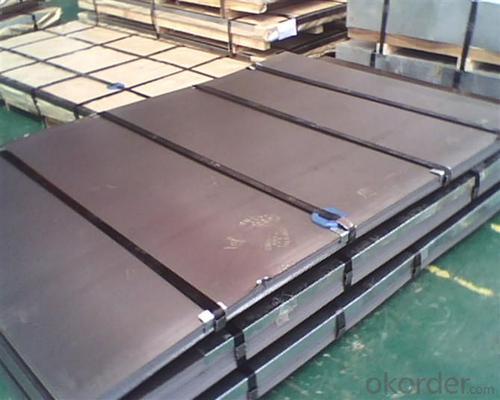

Cold Rolled Steel in Sheets for Galvanizing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only to that of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: How are steel coils used in the manufacturing of agricultural implements?

- Steel coils are used in the manufacturing of agricultural implements by being shaped and formed into various components such as blades, tines, and frames. These components are then assembled or attached to the implements, such as plows, harrows, and cultivators, to enhance their durability, strength, and performance in agricultural activities.

- Q: 911 conspiacy theorists. Can fire melt steel?

- Don't know the differences in steel strength between the WTC towers and the bridge, but I'll tell you they don't always use the strongest steel in buildings. It is a question of value engineering. Engineers do as code requires, and make the determination based on economics of building. If a steel member requires say 48 KSI, with certain span, but if the price is less expensive to use 35 KSI and reduce the span by adding vertical elements then that is an option that the architects, engineers and developers consider. Like I said, don't much about bridge engineering, but in buildings, it isn't always the strongest steel, based on engineering and economics. And BTW, said time and time again, but ok one more time. STEEL DOESN'T NOT HAVE TO MELT FOR FAILURE. IT LOSES STRENGTH WITH HEAT. THAT IS WHY IT MUST BE PROTECTED BY FIRE RETARDANT. BUT IF THE FIRE RETARDANT IS REMOVED BY EXPLOSION, THEN FIRE CAN CAUSE FAILURE. Sorry for the shouting, but I'm not the only one who says that, but people keep saying steel can't melt, but it doesn't have to for failure. If the steel joist had been in concrete, the WTC towers may have stood, at least longer. But hindsight is 20/20.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using tags or stickers that contain important information such as the grade, size, weight, and production details of the coil. Additionally, some coils may also have unique identification numbers or barcodes for easier tracking and inventory management.

- Q: How are steel coils labeled and identified?

- To ensure accurate tracking and handling of steel coils throughout their journey, various methods are employed to label and identify them. The labeling and identification process typically consists of the following steps: 1. Initial Marking: At the outset, the manufacturer's name or logo is affixed to the steel coil, enabling easy identification of the producing company. 2. Unique Identification Number: A distinct identification number, commonly known as a coil number, is assigned to each steel coil. This number is often engraved or imprinted on the surface of the coil and serves the purpose of tracking and managing inventory. 3. Specifications of Size and Weight: Labels indicating the size and weight specifications of the steel coils are attached. This information aids in determining the coil's dimensions and weight capacity, ensuring appropriate handling and transportation arrangements. 4. Indication of Grade and Material: The labeling typically includes information about the grade and material composition of the steel coil. This essential data offers insights into the properties and quality of the steel, guaranteeing its correct utilization in manufacturing processes. 5. Heat or Lot Number: Steel coils may also bear a heat or lot number, which denotes the production batch from which the coil originated. This information contributes to traceability and quality control, simplifying identification in the event of any issues or defects. 6. Barcodes or QR Codes: Many steel coils now feature barcodes or QR codes that can be scanned using automated systems. These codes contain all pertinent information about the coil, streamlining data capture and management throughout the supply chain. Proper labeling and identification of steel coils are of utmost importance for efficient logistics management, inventory control, and quality assurance. By implementing these identification methods, manufacturers, distributors, and end-users can effortlessly track, handle, and utilize steel coils in a secure and productive manner.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they are typically cut and shaped into plates, sheets, or beams that are then used to construct various components of a ship's structure such as the hull, decks, and bulkheads. The coils provide a reliable and durable base material that can withstand the harsh marine environment and ensure the structural integrity and strength of the ship.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: How do steel coil manufacturers handle custom orders?

- Custom orders for steel coils are handled by manufacturers through a methodical process. They begin by comprehending the specific requirements of the customer and engaging in detailed communication to gather information. This includes dimensions, tolerances, and other special needs. Manufacturers may offer technical expertise to ensure the feasibility of the custom order. Once the requirements are clarified, manufacturers proceed with designing and engineering the custom steel coils. Advanced software and engineering tools are utilized to create detailed designs and specifications that cater to the customer's unique needs. Prototypes or samples may be created for the customer's approval before full-scale production. After the design phase, manufacturers initiate the production process by sourcing the appropriate raw materials, such as steel coils with the desired composition and thickness. The coils undergo various manufacturing stages, including cutting, shaping, and forming, to achieve the desired dimensions and shapes. Specialized equipment and machinery guarantee precision and accuracy throughout the production process. Quality control plays a crucial role in handling custom orders. Manufacturers conduct thorough inspections and testing procedures at different stages of production to ensure that the custom coils meet the customer's specifications and industry standards. This involves checking for dimensional accuracy, surface finish, mechanical properties, and other specific requirements. Third-party inspection agencies may be involved, and manufacturers may provide customers with test reports and certifications to ensure quality assurance. Lastly, once the custom steel coils are manufactured and pass all quality checks, they are meticulously packaged and delivered to the customer. Manufacturers ensure proper packaging and shipping methods to prevent damage during transit and ensure the coils reach the customer in optimal condition. In summary, steel coil manufacturers handle custom orders by collaborating closely with customers, designing and engineering specialized coils, maintaining quality control throughout the production process, and delivering the custom coils to the customer's satisfaction. This systematic approach enables manufacturers to meet the unique requirements of each customer and provide high-quality custom steel coils.

- Q: What are the different types of steel coil finishes for aesthetics?

- There are several different types of steel coil finishes that are commonly used for aesthetic purposes. These include brushed finishes, polished finishes, embossed finishes, and patterned finishes. Each of these finishes can give the steel coil a unique look and texture, allowing it to be used in various design applications.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as they are typically used to construct the pump housing and impellers, providing the necessary strength and durability for handling high-pressure fluids and withstanding harsh operating conditions. The steel coils are processed and shaped into various components, ensuring the structural integrity and reliability of the pump, ultimately contributing to its efficient operation and long lifespan.

- Q: i heard steel type is good and i don't have any i have defeated all the trainers up to the icicle badge (i have got the icicle badge but not the one after) where can i get one?

- you can get a steelix at the cave just before the elite four. but if you have wifi, you can trade for one.

Send your message to us

Cold Rolled Steel in Sheets for Galvanizing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords