Hot-Dip Galvanized Steel Coil Used for Industry with Our So Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

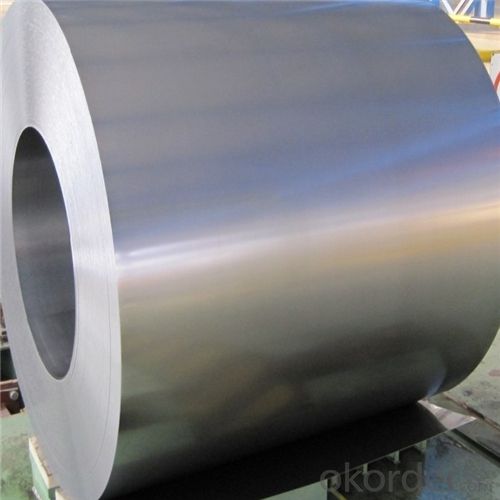

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

We can supply galvanized corrugatedsheet with high quality and competitive price. Our corrugated board is a high strength,

durable and generally used for a steel building decoration. As a result of high strength steel, plus a reasonable size design make

it widely used in a variety of architectural roof, walls, easy installation, flexible, no building restrictions on any factors.

- Q: What are the different coil leveling methods used for steel coils?

- There are several coil leveling methods used for steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling involves passing the coil through a series of rollers to remove any curvature and create a flat surface. Stretcher leveling involves stretching the coil in different directions to remove any shape irregularities. Tension leveling applies tension to the coil during the leveling process to eliminate any residual stresses and create a uniformly flat product.

- Q: How do steel coils contribute to the renewable energy equipment industry?

- The renewable energy equipment industry relies heavily on steel coils, as they are a crucial component in the manufacturing process of various renewable energy technologies. Wind turbines, in particular, heavily rely on steel coils for their construction. The tower, nacelle, and rotor blades of wind turbines all require steel coils. When it comes to wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support. These coils are rolled and welded together to form the tower, ensuring its strength and durability against the wind forces. Steel coils are also used in the production of the nacelle, which houses the generator and other essential components. Steel coils also play a significant role in the manufacturing of rotor blades for wind turbines. These blades are responsible for capturing wind energy and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength to withstand the aerodynamic forces. These coils are often combined with composite materials to optimize the performance and efficiency of the blades. In addition to wind turbines, steel coils are utilized in other renewable energy technologies such as solar panels. In the manufacturing process of solar panels, steel coils are used to create frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to effectively capture sunlight and convert it into electricity. To summarize, steel coils are an integral part of the renewable energy equipment industry. They provide the strength, durability, and structural support required by various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector. This advancement is crucial in the global transition towards cleaner and more sustainable sources of energy.

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they provide the necessary material for forming and shaping various components such as pipes, mufflers, and catalytic converters. These coils are typically processed through cutting, bending, and welding techniques to create the required shapes and sizes for the different parts of an exhaust system.

- Q: How do steel coils contribute to the agricultural sector?

- The agricultural sector benefits greatly from the use of steel coils in various ways. To begin with, these coils are instrumental in the production of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are indispensable for carrying out farming operations efficiently, thereby helping farmers increase productivity and cut down on labor costs. The robustness and durability of steel coils ensure the machinery's ability to endure the harsh conditions of the agricultural environment. Furthermore, steel coils find application in the construction of storage facilities and warehouses for agricultural products. To safeguard crops from damage, these structures must be strong and resistant to external elements. Steel coils provide the required strength and stability for the construction of such storage facilities, thereby ensuring the secure storage of agricultural produce. In addition, steel coils are employed in the fabrication of fencing and other agricultural infrastructure. Fencing is of utmost importance in protecting crops from animals and trespassing. Steel coils serve as a robust material for fencing, guaranteeing the security and protection of agricultural lands. Moreover, steel coils are utilized in the manufacture of irrigation pipes and systems. Efficient irrigation is crucial for the growth and yield of crops, particularly in areas with limited water resources. Steel coils are used to create pipes capable of withstanding high pressure and resistant to corrosion, thereby ensuring the effective distribution of water throughout agricultural fields. In conclusion, steel coils play a vital role in the agricultural sector, providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: i wanna know all the similarities between iron and steel

- Iron is raw from iron ore, steel has other metals added such as alloys or copper to give tesil strength and flexibility

- Q: I'm not really sure if carbon steel is considered a metallic material.

- Carbon and iron are both metallic.... so yes. You leave the iron laying in the forge - and it soaks up carbon atoms from the charcoal - so that as the steeling process goes on, the original iron becomes harder and harder.

- Q: How are steel coils used in the production of metal ceilings?

- Steel coils are an essential component in the production of metal ceilings. These coils, which are typically made of high-quality steel, are used to create the base material for manufacturing metal ceiling panels. The first step in the process involves uncoiling the steel coils and feeding them into a roll forming machine. This machine gradually shapes the steel into the desired profile for the ceiling panels. The coils are passed through a series of rollers, which bend and shape the steel into the required dimensions and design. Once the steel has been shaped, it is then cut into individual panels of the desired length. These panels are then subjected to various finishing processes such as surface treatment, painting, or powder coating to enhance their appearance and durability. Steel coils are preferred in the production of metal ceilings due to their excellent strength and rigidity. They provide a sturdy foundation for the ceiling panels, ensuring their longevity and resistance to deformation. Moreover, steel coils offer superior fire resistance, making them a safe choice for use in commercial and industrial buildings. In addition to their structural benefits, steel coils also allow for a wide range of design possibilities. The malleability of steel allows manufacturers to create intricate patterns and textures on the surface of the ceiling panels, providing aesthetic appeal and enhancing the overall interior design. Overall, steel coils are an integral part of the production process for metal ceilings. They provide the necessary strength, durability, and versatility required for creating high-quality and visually appealing ceiling panels used in various commercial and residential spaces.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Our So Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords