Cold Rolled Steel Coils Grade 304 NO.2B made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

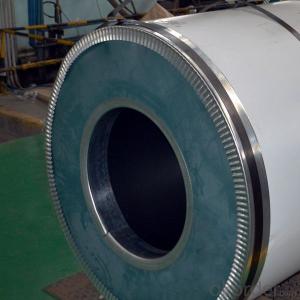

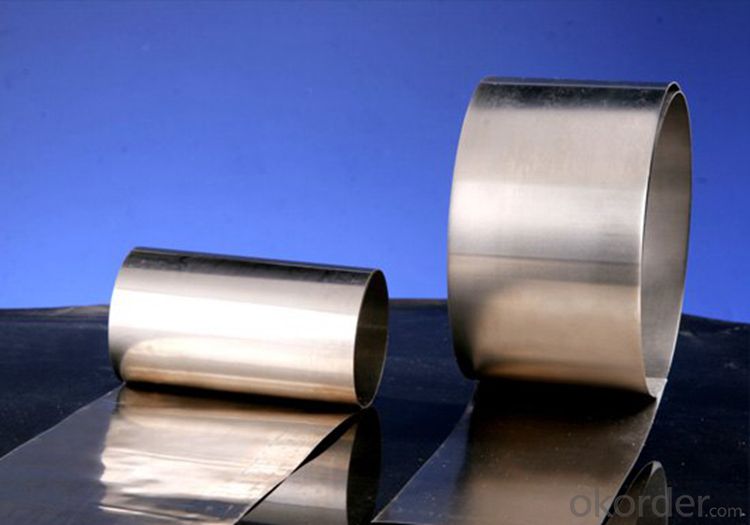

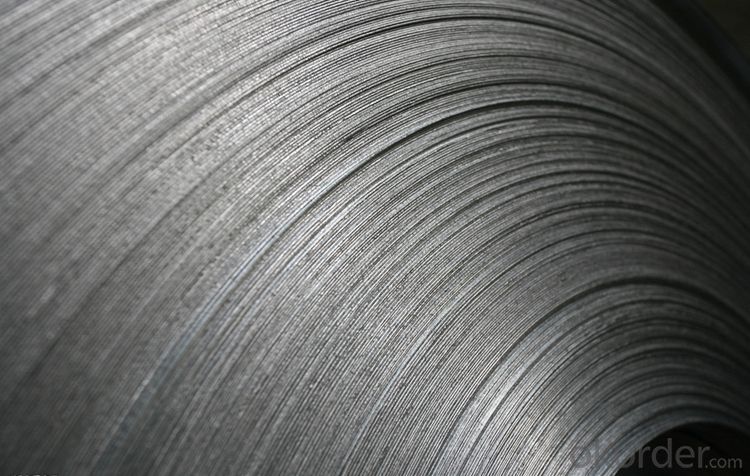

Cold Rolled Steel Coils Grade 304 NO.2B made in China

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Detail picture of Products:

Application:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets can be used for hygienic environments. Stainless steel is a popular choice for such environments due to its inherent properties that make it highly resistant to corrosion, heat, and chemical damage. Its smooth and non-porous surface is easy to clean, preventing the accumulation of bacteria, mold, or other contaminants. Stainless steel is also non-reactive and does not release any harmful substances, making it suitable for sensitive environments such as food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Additionally, stainless steel is durable and long-lasting, providing excellent hygiene and cleanliness for extended periods. Overall, stainless steel sheets are a reliable and hygienic choice for various applications in environments that prioritize cleanliness and sanitation.

- Q: How do you prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to avoid exposure to corrosive substances such as chloride-based cleaners or acids. Regular cleaning using mild, non-abrasive cleaners and soft cloths is recommended. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or saltwater environments can help prevent pitting. Regular inspections and prompt repairs of any scratches or damages can also contribute to maintaining the integrity of stainless steel sheets and preventing pitting.

- Q: Are stainless steel sheets resistant to galvanic corrosion?

- Yes, stainless steel sheets are highly resistant to galvanic corrosion.

- Q: What's the difference between 304 stainless steel and 314?

- All belong to austenitic stainless steel, 304 is the most common, and 314 of the alloy content is higher than 304, better performance, especially high pressure heat resistance.

- Q: What are the different types of stainless steel sheet perforations available?

- There exists a variety of stainless steel sheet perforations, each possessing its own distinctive characteristics and applications. Among the most prevalent types are: 1. Round hole perforations: These perforations, characterized by evenly spaced round holes, are the simplest and most commonly employed. They ensure sufficient airflow and visibility. 2. Square hole perforations: Similar to their round counterparts, square hole perforations offer a distinct aesthetic and may be utilized for ventilation or decorative purposes. 3. Slotted perforations: Elongated in shape, slotted holes provide a larger open area compared to round or square holes. Consequently, they are often employed for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes, featuring an exclusive pattern, are frequently used for architectural or decorative applications. They are also effective in facilitating airflow and visibility. 5. Decorative perforations: These perforations exhibit diverse shapes and designs, such as floral, geometric, or abstract patterns. Primarily employed for decorative purposes, they are commonly found in building facades or interior design. 6. Micro-perforations: These minute holes, typically less than 1mm in diameter, are utilized in applications necessitating high precision and fine filtration, like speaker grills or air diffusers. When selecting the appropriate perforation type, it is crucial to consider the specific requirements of your application. Factors such as open area, strength, visibility, and aesthetics must all be carefully evaluated to guarantee the most suitable choice for your specific needs.

- Q: Are stainless steel sheets suitable for decorative applications?

- Yes, stainless steel sheets are suitable for decorative applications. Stainless steel is a versatile material that offers both durability and aesthetic appeal, making it ideal for various decorative purposes. It is commonly used in interior design, architecture, and furniture manufacturing due to its sleek and modern look. Stainless steel sheets can be shaped, cut, and fabricated into different patterns, textures, and finishes, allowing for endless design possibilities. Whether it is for wall cladding, backsplashes, countertops, or decorative accents, stainless steel sheets can enhance the visual appeal of any space. Additionally, stainless steel is resistant to corrosion, staining, and heat, ensuring its long-lasting beauty even in challenging environments.

- Q: Can stainless steel sheets be used for water filtration?

- Yes, stainless steel sheets can be used for water filtration. Stainless steel is known for its corrosion resistance, durability, and ability to withstand high temperatures, making it a suitable material for water filtration applications. Stainless steel sheets can be formed into various filter elements such as screens, mesh, or cartridges, which efficiently remove impurities and contaminants from water. The fine mesh size of stainless steel sheets allows for effective filtration while maintaining a high flow rate. Additionally, stainless steel is non-reactive and does not release harmful substances into the filtered water, ensuring its safety for consumption. Overall, stainless steel sheets are a reliable choice for water filtration due to their excellent mechanical properties and resistance to corrosion.

- Q: Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a durable and versatile material that offers many advantages for façade applications. It is resistant to corrosion, weathering, and staining, making it an ideal choice for exterior use. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for a wide range of design options. Additionally, stainless steel can be finished in different ways, such as brushed, polished, or colored, providing further aesthetic possibilities. Its strength and rigidity also make it suitable for large-scale installations. Overall, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a popular choice for architectural façades.

- Q: What are the benefits of using perforated stainless steel sheets?

- Perforated stainless steel sheets offer several benefits. Firstly, they provide excellent ventilation and airflow, making them ideal for applications where aeration is crucial, such as in HVAC systems or industrial structures. Secondly, the perforations allow for enhanced visibility, enabling the passage of light and maintaining a clear line of sight. Additionally, the perforations can aid in noise reduction by absorbing sound waves. Lastly, stainless steel sheets are highly durable, corrosion-resistant, and easy to maintain, making them a cost-effective solution for various industries.

- Q: What are the different types of textured finishes available for stainless steel sheets?

- There are several types of textured finishes available for stainless steel sheets, including brushed, embossed, hammered, linen, and mirror finishes.

Send your message to us

Cold Rolled Steel Coils Grade 304 NO.2B made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords