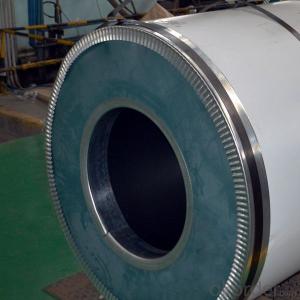

Cold Rolled Steel Coils Grade 304 NO.2B from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Steel Coils Grade 304 NO.2B from China

Products Despription

Name:stainless steel coils/plates/sheets

Delivery Port :Any Port, China

Coil Weight :20 Tons

Grade :201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc.

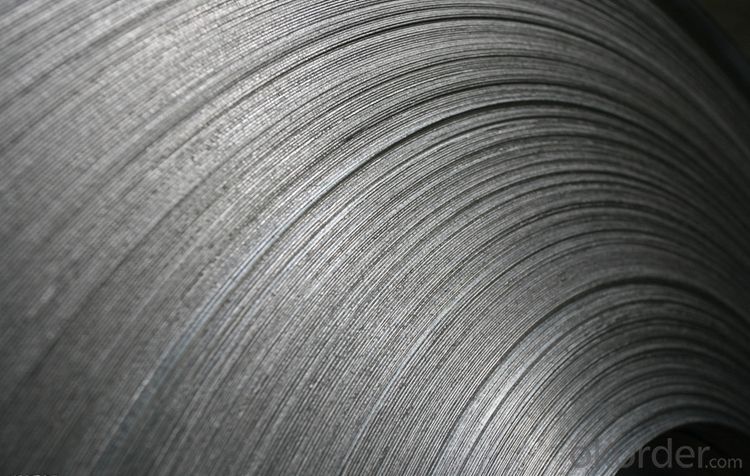

Technique :Cold Rolled

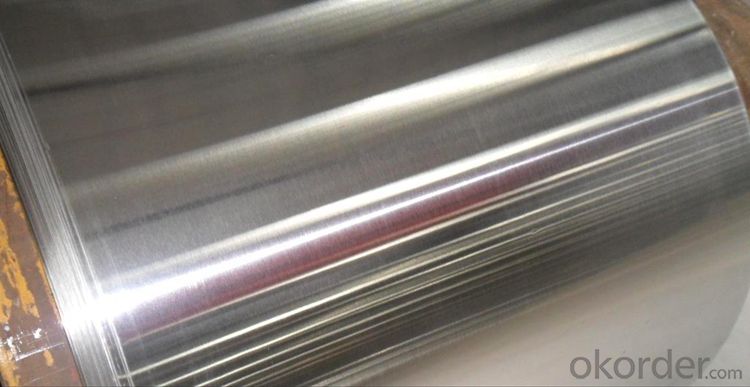

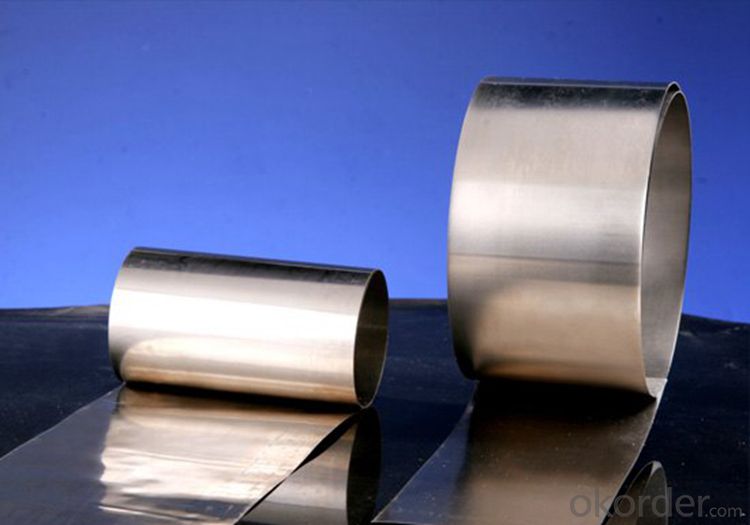

Finish :2B, BA, 2D, No1, No2, No4,NO.8,SB etc

Edge :Mill Edge / Slitting Edge

Size: Thickness0.3-6mm,Width:280-2000mm

Package :as customer's requirement

Place of Origin :made in China

MOQ :20 Tons

Payment Terms :100% LC at sight,or 100%TT in advance

Delivery Time :With 15- 20 days after deposit

Detail of Picture

Application

2B Medical equipment, Food industry, Construction material, Kitchen utensils.

NO.1 Chemical tank, pipe.

- Q: What are the different types of stainless steel sheet finishes for architectural applications?

- There are several different types of stainless steel sheet finishes that are commonly used in architectural applications. These finishes are applied to the surface of the stainless steel sheet to enhance its appearance and provide additional protection against corrosion and wear. 1. No. 1 Finish: This is the most common type of stainless steel sheet finish. It is also known as "hot rolled annealed and pickled" finish. In this finish, the stainless steel sheet is hot rolled, resulting in a dull, rough surface. It is then annealed and pickled to remove any scale or impurities, leaving a clean, uniform surface. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after it has been annealed and pickled. It results in a smooth, reflective surface with a slight grainy texture. No. 2B finish is commonly used for applications that require a high level of corrosion resistance and a polished appearance. 3. No. 4 Finish: Also known as "brushed finish," No. 4 finish is achieved by mechanically polishing the stainless steel sheet with abrasive belts or brushes. It creates a satin-like appearance with fine parallel lines. No. 4 finish is often used for decorative purposes in architectural applications such as wall panels, elevator interiors, and column covers. 4. No. 8 Mirror Finish: This finish is achieved by mechanically polishing the stainless steel sheet to a highly reflective mirror-like surface. It provides a bright, reflective appearance and is commonly used for decorative applications such as wall cladding, signage, and decorative trim. 5. Bead Blasted Finish: In this finish, the stainless steel sheet is blasted with fine glass beads to create a textured, matte surface. Bead blasted finish offers a unique aesthetic and is often used in applications where a non-reflective, tactile surface is desired, such as elevator doors, handrails, and countertops. 6. Patterned Finish: Patterned finishes are achieved by embossing or etching the stainless steel sheet with various patterns or textures. This creates a decorative surface that adds visual interest to architectural applications. Patterned finishes are commonly used for wall panels, ceiling tiles, and decorative screens. These are just a few of the most common stainless steel sheet finishes used in architectural applications. Each finish offers its own unique aesthetic and functional characteristics, allowing architects and designers to choose the most suitable finish for their specific project requirements.

- Q: Are stainless steel sheets resistant to chlorine?

- Yes, stainless steel sheets are highly resistant to chlorine due to the passive film formed on their surface, which helps protect them from corrosion caused by chlorine exposure.

- Q: What are the benefits of using etched stainless steel sheets in signage?

- There are several benefits of using etched stainless steel sheets in signage. Firstly, stainless steel is highly durable and resistant to corrosion, making it suitable for outdoor applications and ensuring longevity. Secondly, the etching process allows for intricate and detailed designs, resulting in visually appealing signage. Additionally, stainless steel is easy to clean and maintain, ensuring that the signage remains in good condition. Finally, stainless steel has a professional and modern look, adding a touch of sophistication to any signage project.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q: 304 stainless steel plate price ups and downs affected by what factors?

- That is, inventory relations, supply and demand has been constantly guide prices, and inventory is a good response to the current market supply and demand. Oversupply, stainless steel prices, inventory backlog. Supply falls short of demand, and inventories are very tight as prices rise. If a series of stainless steel prices are too high, then the stainless steel market will appear in this series of alternatives. Substitutes generally have many advantages, such as low prices, cheap materials, superior performance and so on. Therefore, the emergence of substitutes can also cause price fluctuations.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are several different types of stainless steel sheet embossing patterns available. Some of the most common patterns include: 1. Diamond: This pattern features a series of diamond-shaped indentations evenly spaced across the surface of the sheet. It creates a visually appealing and textured appearance. 2. Linen: The linen pattern resembles the texture of linen fabric, with a series of parallel lines running in one direction and perpendicular lines intersecting them. It adds a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the surface of the sheet. It is commonly used in architectural applications to add visual interest and a tactile feel. 4. Leather: This pattern replicates the texture of leather, with a series of irregular lines and indentations. It provides a unique and luxurious appearance to stainless steel sheets. 5. Hammered: The hammered pattern features a series of irregular indentations that resemble the marks made by a hammer. It adds a rustic and handcrafted look to stainless steel sheets. 6. Checkerboard: This pattern consists of a grid of squares, with alternating squares raised or recessed. It creates a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern features a series of curved lines that resemble ocean waves. It adds a dynamic and flowing look to stainless steel sheets. These are just a few examples of the many different types of stainless steel sheet embossing patterns available. Each pattern can be customized in terms of size, depth, and spacing to suit specific design preferences and applications.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a popular choice for food processing equipment due to its excellent corrosion resistance, durability, and hygienic properties. It is highly resistant to staining, rusting, and contamination, making it suitable for direct contact with food. Stainless steel sheets are commonly used for surfaces such as countertops, work tables, and food preparation areas in commercial kitchens and food processing facilities. Additionally, stainless steel is easy to clean and maintain, which is crucial in ensuring food safety and compliance with industry regulations.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- Some of the different types of stainless steel sheet finishes for automotive applications include brushed, polished, satin, mirror, and textured finishes. These finishes vary in terms of appearance, texture, and level of reflectivity, providing options for various aesthetic preferences and functional requirements in the automotive industry.

- Q: Are stainless steel sheets resistant to radiation?

- Generally speaking, stainless steel sheets exhibit a high level of resistance to radiation. This is because stainless steel is renowned for its ability to withstand corrosion and oxidation, making it a suitable choice for industries that deal with radiation exposure, such as nuclear power plants, medical facilities, and laboratories. The resistance to radiation exhibited by stainless steel can be attributed to its composition, which includes chromium, nickel, and other alloying elements. These elements create a protective oxide layer on the surface of the stainless steel, effectively preventing radiation from penetrating the material. However, it is important to note that the degree of radiation resistance can vary depending on the specific grade and thickness of the stainless steel sheet. To ensure optimal performance in radiation-prone environments, it is recommended to seek advice from experts or consult specific technical specifications.

- Q: Can stainless steel sheets be used for elevator cabins?

- Yes, stainless steel sheets can be used for elevator cabins. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator cabins. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for elevator interiors.

Send your message to us

Cold Rolled Steel Coils Grade 304 NO.2B from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords