Stainless Steel Sheet price 409 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

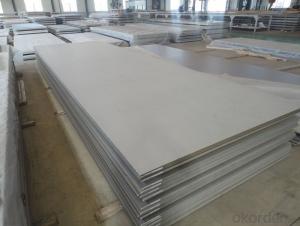

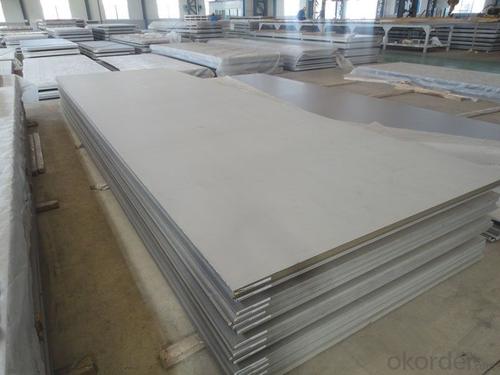

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

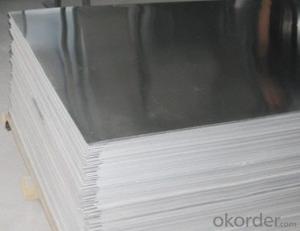

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

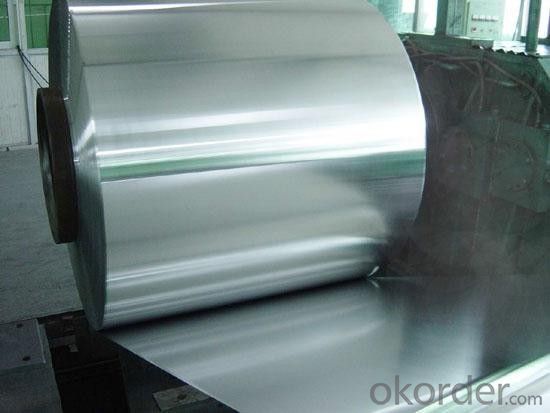

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Indeed, stainless steel sheets prove to be apt for cleanroom applications. The reason lies in the fact that stainless steel boasts exceptional resistance against corrosion, a trait that holds immense importance in cleanroom environments where the utmost cleanliness and hygiene are paramount. Furthermore, stainless steel exhibits remarkable durability and effortless cleanability, rendering it an ideal choice for maintaining cleanliness standards in cleanrooms. Moreover, stainless steel possesses a non-porous nature, thereby preventing the absorption of contaminants and facilitating easy sanitization. Its resistance to chemicals further adds to its suitability for cleanroom applications that involve the use of potent disinfectants or cleaning agents. All in all, stainless steel sheets provide a dependable and hygienic surface for cleanroom applications.

- Q: What are the fire resistance properties of stainless steel sheets?

- Stainless steel sheets have excellent fire resistance properties due to their high melting point and low thermal conductivity. They can withstand high temperatures without losing their structural integrity, making them suitable for use in fire-resistant applications.

- Q: Can stainless steel sheets be used for decorative screens?

- Definitely! Decorative screens can be made using stainless steel sheets. Stainless steel is a highly flexible material, often chosen for its pleasing appearance and long-lasting nature. It can be effortlessly molded into different patterns, making it perfect for crafting decorative screens. Moreover, stainless steel is resistant to rust and can endure extreme weather conditions, making it suitable for both indoor and outdoor purposes. Its smooth and contemporary look enhances any area, making stainless steel sheets a favored option for decorative screens in homes and businesses alike.

- Q: Are stainless steel sheets suitable for elevator buttons?

- Yes, stainless steel sheets are suitable for elevator buttons. Stainless steel is a durable and corrosion-resistant material, making it an ideal choice for elevator buttons that are frequently touched and exposed to various environmental conditions. Additionally, stainless steel has a sleek and modern appearance, making it aesthetically pleasing for elevator buttons.

- Q: What are the applications of stainless steel sheets?

- Due to their various beneficial properties, stainless steel sheets find a wide range of applications. Some common uses include: 1. Construction: Stainless steel sheets are widely utilized in the construction industry for various purposes. They provide durability, corrosion resistance, and an attractive appearance, making them suitable for cladding, roofing, wall panels, as well as structural components like beams, columns, and reinforcement bars. 2. Kitchenware: The production of kitchen appliances and utensils extensively involves stainless steel sheets. They are used to manufacture sinks, countertops, backsplashes, and cabinets. Stainless steel is preferred in the kitchen due to its hygienic properties, resistance to staining and corrosion, and ease of cleaning. 3. Automotive industry: Stainless steel sheets are utilized in the automotive industry for producing various components. They are used in the manufacturing of exhaust systems, mufflers, fuel tanks, and decorative trims. Stainless steel sheets offer corrosion resistance, heat resistance, and durability in harsh automotive environments. 4. Medical equipment: The medical field widely employs stainless steel sheets for the production of surgical instruments, implants, and medical equipment. The corrosion resistance and biocompatibility of stainless steel make it an ideal material for these applications. 5. Chemical processing: The chemical industry heavily relies on stainless steel sheets due to their corrosion resistance and ability to withstand high temperatures. They are used for manufacturing storage tanks, pipes, valves, and pressure vessels. Stainless steel sheets are preferred in chemical processing applications to prevent contamination and ensure process safety. 6. Energy and power generation: Stainless steel sheets are utilized in power plants, refineries, and other energy generation facilities. They are used in manufacturing boilers, heat exchangers, and condensers due to their high-temperature resistance, corrosion resistance, and strength. 7. Decorative applications: Stainless steel sheets are frequently employed in architectural and decorative applications. They are used for decorative panels, elevator doors, signage, and furniture. The versatility of stainless steel allows for various finishes and textures, making it a popular choice in interior and exterior design. In conclusion, stainless steel sheets are incredibly versatile and find numerous applications in various industries. Their corrosion resistance, durability, strength, and aesthetic appeal make them an ideal material for a wide range of purposes.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, certain measures can be taken. First, ensuring proper cleaning and maintenance is crucial. Regularly cleaning the stainless steel sheets with mild detergent and water, followed by thorough rinsing and drying, helps remove any contaminants that can lead to corrosion. Additionally, avoiding exposure to corrosive substances like chloride-based cleaners or harsh chemicals is important. Applying a protective coating or passivating the stainless steel surface can also provide an extra barrier against corrosion. Passivation involves treating the stainless steel with a mild oxidizing agent to promote the formation of a passive oxide layer, which enhances the metal's resistance to corrosion. Proper design and installation practices are equally vital. Avoiding the use of dissimilar metals in contact with stainless steel sheets and ensuring proper sealing and gasketing in joints or crevices can prevent crevice corrosion. Adequate ventilation and avoiding stagnant conditions can also help minimize corrosion risks. Regular inspection and maintenance are necessary to identify and address any signs of corrosion promptly. This includes checking for signs of pitting or crevices, addressing any damage or scratches, and promptly repairing or replacing any corroded areas.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Stainless steel plate material is hard, not easy to shape, the color is monotonous, but the color is bright, not distortion;

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- In industrial applications, various types of stainless steel sheet finishes are commonly utilized. These finishes serve different purposes in terms of durability, resistance to corrosion, and aesthetics. 1. No. 1 Finish: This finish is achieved through a process of hot rolling, annealing, and pickling, resulting in a rough and dull surface. It finds its application in structural components or areas where a smooth surface is not essential. 2. No. 2B Finish: Achieved by cold rolling, annealing, and pickling, this finish offers a moderately reflective and smooth surface. It is commonly used in applications where both corrosion resistance and appearance are important, such as kitchen appliances, architectural components, and food processing equipment. 3. No. 4 Finish: This finish is obtained by polishing with abrasive belts or brushes, resulting in a matte appearance. It is often employed in applications where a decorative finish is desired, such as furniture, elevator panels, and signage. 4. No. 8 Finish: Also known as a mirror finish, this is the most reflective finish available for stainless steel sheets. It is achieved by progressively polishing with finer abrasives until a highly reflective surface is obtained. This finish is commonly used for architectural accents, automotive trims, and decorative items that require a high level of reflectivity and a pleasing appearance. 5. BA Finish: This finish is achieved through annealing in a controlled atmosphere furnace, resulting in a highly reflective and smooth surface. It is commonly used in applications where a mirror-like finish is desired, such as decorative items, reflectors, and light fixtures. These are just a few examples of the various stainless steel sheet finishes commonly employed in industrial applications. Each finish possesses unique properties and is suitable for different purposes. Therefore, it is crucial to carefully consider the specific requirements of the application when selecting a finish.

- Q: Can stainless steel sheets be used for signage?

- Stainless steel sheets are indeed capable of serving as signage. This material possesses durability and longevity, being highly resistant to corrosion, thereby rendering it suitable for both indoor and outdoor applications. Its sleek and contemporary appearance contributes to its popularity across various signage types, encompassing company logos, directional signs, nameplates, and even expansive outdoor billboards. The flexibility of stainless steel sheets allows for easy customization through cutting, engraving, or laser-etching, thereby offering a vast array of creative possibilities. Furthermore, the choice of stainless steel signage often stems from its ability to withstand adverse weather conditions, UV rays, and acts of vandalism, thereby preserving the integrity and legibility of the signage for numerous years.

- Q: Can stainless steel sheets be used for architectural columns?

- Architectural columns can indeed utilize stainless steel sheets. Renowned for its durability and versatility, stainless steel proves to be an exceptional material, providing outstanding resistance against corrosion. This exceptional trait makes it a fitting choice for both indoor and outdoor applications. The polished and contemporary look of stainless steel further enhances the visual allure of architectural designs. Moreover, stainless steel sheets can be tailor-made into different sizes and shapes, offering flexibility in column design. Be it for residential, commercial, or industrial ventures, stainless steel sheets emerge as a favored option for architectural columns, owing to their robustness, long lifespan, and captivating appearance.

Send your message to us

Stainless Steel Sheet price 409 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords