Cold Rolled Plate Steel,Steel Coils,Made In China 2016 Newly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 30-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

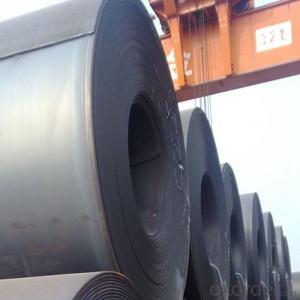

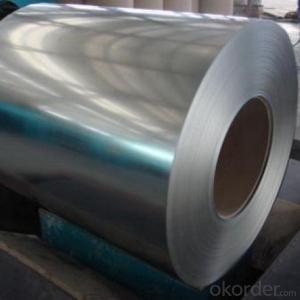

DETAILED PICTURES FOR STEEL COILS

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: What is the difference between a self-color and painted steel sheet?

- A steel sheet that has not been coated or treated with any additional colors or finishes is referred to as a self-color steel sheet. It maintains the steel surface's natural color and appearance, which is typically a metallic gray or silver. Conversely, a painted steel sheet is one that has been coated with a layer of paint or another protective finish. This coating serves multiple purposes, including enhancing the steel sheet's aesthetic appeal, providing additional protection against rust and corrosion, and increasing its durability. The primary distinction between a self-color and painted steel sheet lies in the presence or absence of a coating. While a self-color sheet preserves the raw and natural appearance of the steel, a painted sheet offers a wide array of color options, enabling customization and harmonization with various design schemes. Furthermore, the existence of a paint or protective coating on a steel sheet provides an extra layer of defense against environmental elements such as moisture, chemicals, and UV rays. This helps prevent the steel from corroding or deteriorating over time, thereby extending its lifespan and ensuring its performance in various applications. To summarize, the main contrast between a self-color and painted steel sheet is the presence or absence of a coating. While a self-color sheet retains the natural appearance of steel, a painted sheet offers added protection, customization options, and aesthetic appeal.

- Q: Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets are suitable for food-grade applications.

- Q: Are steel sheets non-magnetic?

- No, steel sheets are generally magnetic.

- Q: How do steel sheets compare to fiberglass sheets?

- Steel sheets and fiberglass sheets have distinct characteristics that make them suitable for different applications. Steel sheets are known for their high strength and durability. They are capable of withstanding heavy loads and have excellent resistance to impact and abrasion. Steel sheets also offer exceptional fire resistance, making them ideal for applications where fire safety is a concern. Furthermore, steel sheets are relatively low maintenance and can withstand harsh weather conditions, making them a popular choice for outdoor structures such as roofing and siding. On the other hand, fiberglass sheets are lightweight and have excellent corrosion resistance. They are typically made from woven glass fibers embedded in a resin matrix, which gives them high strength-to-weight ratio. Fiberglass sheets are also non-conductive, making them suitable for applications where electrical insulation is required. Additionally, fiberglass sheets are highly transparent to electromagnetic waves such as radio waves, making them commonly used in industries such as telecommunications. While steel sheets offer superior strength and are better suited for heavy-duty applications, fiberglass sheets excel in areas where weight, corrosion resistance, and electrical insulation are important factors. Ultimately, the choice between steel sheets and fiberglass sheets depends on the specific requirements of the application and the desired characteristics needed to fulfill those requirements.

- Q: What is the process of laminating steel sheets?

- To create a composite material that surpasses the strength and durability of conventional steel, the lamination of steel sheets encompasses various sequential steps. Initially, the steel sheets undergo a thorough cleaning and preparation process to eliminate any impurities or contaminants. This step is vital in guaranteeing a robust bond between the layers and preventing any flaws in the end product. Subsequently, an adhesive layer is administered onto one or both sides of the steel sheets. The selection of the adhesive is contingent upon the desired characteristics of the laminated steel, with options ranging from thermosetting resins to thermoplastic materials. Once the adhesive is applied, the steel sheets are assembled, with the adhesive layer(s) sandwiched in between. To initiate the bonding process, the sheets are subjected to intense heat and pressure. This can be achieved through the utilization of a hydraulic press or a hot rolling mill. The combined effect of heat and pressure causes the adhesive to liquefy and flow, forming a sturdy chemical bond between the steel sheets. The application of high pressure ensures the even distribution of the adhesive and fills any gaps or irregularities that may exist between the sheets. Upon the completion of the bonding process, the laminated steel sheets are cooled and trimmed to the desired size and shape. They can then undergo further processing, such as cutting, bending, or welding, to fulfill specific application requirements. In summary, the process of laminating steel sheets encompasses a series of actions, including cleaning and prepping the sheets, adhesive application, sheet stacking, exposure to high temperature and pressure, cooling, and finalizing the shape. This process results in a composite material boasting enhanced strength, corrosion resistance, and other desirable properties when compared to traditional steel.

- Q: Can steel sheets be used for decorative purposes?

- Yes, steel sheets can be used for decorative purposes. They can be shaped, cut, and finished in various ways to create unique and visually appealing designs. Steel sheets are often used in architecture, interior design, and artwork, adding a modern and industrial aesthetic to spaces.

- Q: What is the difference between a hot rolled and cold rolled galvanized steel sheet?

- The main difference between a hot rolled and cold rolled galvanized steel sheet is the process in which they are made. Hot rolled galvanized steel sheets are produced by rolling the steel at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold rolled galvanized steel sheets are processed at lower temperatures, allowing for a smoother surface finish and more precise dimensions. Additionally, the cold rolling process also tends to make the steel stronger and more durable.

- Q: Are there any restrictions on the thickness of the steel plate, such as the minimum thickness of the steel plate?

- If the intensity is enough, you should be the first 4mm for the economy. Carbon steel plate, with electrode arc welding, 2 diameter welding electrode on line.If it is stainless steel, tungsten argon arc welding is better

- Q: What is the process of electroplating steel sheets?

- The process of electroplating steel sheets involves immersing the steel sheets in a solution that contains metal ions, typically nickel or chromium. An electric current is then passed through the solution, causing the metal ions to be attracted to the steel sheets and deposit onto their surface. This creates a thin, protective layer of metal that enhances the steel sheets' appearance, corrosion resistance, and durability.

- Q: Can steel sheets be used in construction projects?

- Yes, steel sheets can definitely be used in construction projects. They are commonly used for various applications such as roofing, walls, flooring, and structural framework due to their strength, durability, and versatility. Steel sheets offer excellent load-bearing capacity, fire resistance, and resistance to environmental factors, making them a popular choice in both residential and commercial construction projects.

Send your message to us

Cold Rolled Plate Steel,Steel Coils,Made In China 2016 Newly

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords