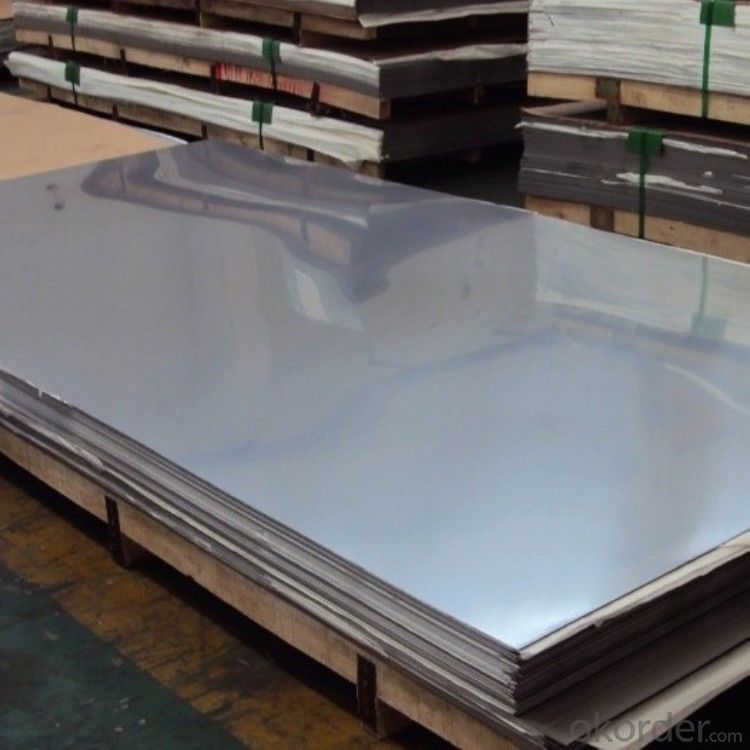

Hot Rolled Plate Steel 2016 New Desigh Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can steel sheets be used in architectural or decorative applications?

- Yes, steel sheets can be used in architectural or decorative applications. Steel sheets offer durability, versatility, and a sleek aesthetic that make them suitable for various architectural and decorative purposes such as cladding, roofing, wall panels, and interior design elements.

- Q: What are the different storage methods for steel sheets?

- There are several different storage methods for steel sheets, including vertical storage racks, horizontal storage racks, cantilever racks, shelving systems, and pallet racking. Each method offers distinct advantages in terms of space utilization, ease of access, and efficient handling of the steel sheets. The choice of storage method depends on the size, weight, and quantity of steel sheets, as well as the available space and specific requirements of the facility.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are commonly used in automotive applications due to their high strength, durability, and formability. They provide structural support, enhance crash safety, and can be easily shaped into various automotive components, making them suitable for the automotive industry.

- Q: What material is steel plate against drilling?

- All high nickel, high tungsten, or both titanium (tungsten carbide and titanium carbide), cobalt, molybdenum, niobium and other elements of the steel can be drilled.

- Q: How do I print the steel plate?

- Because in the stencil lettering all strokes forming holes, printing pigment through the hole leakage in the following paper

- Q: Can the steel sheets be easily engraved or etched?

- Yes, steel sheets can be easily engraved or etched using various techniques such as laser engraving or chemical etching.

- Q: Which is good, z15 grade steel plate and z25 grade steel plate?

- It is obvious that the fracture resistance of lamellar fracture is stronger than that of fracture shrinkage, that is, the lamellar tearing resistance of Z25 is better than that of Z15.

- Q: Can steel sheets be used for balcony railings?

- Yes, steel sheets can be used for balcony railings. Steel is a strong and durable material that can provide stability and security to balcony railings.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets, particularly those that are coated or galvanized, exhibit excellent corrosion resistance due to their inherent properties and protective coatings. The corrosion resistance of steel sheets can be attributed to the presence of iron oxide (rust), which forms a protective layer over the steel, preventing further corrosion. Additionally, various coatings like zinc or paint can be applied to further enhance their resistance against corrosion, making steel sheets a reliable choice for various applications.

- Q: Can steel sheets be used for making HVAC ducts?

- Indeed, it is possible to utilize steel sheets in the construction of HVAC ducts. Owing to its robustness, longevity, and fire-resistant attributes, steel is widely employed as a material for fabricating HVAC ductwork. To construct the ductwork, steel sheets are typically sliced, shaped, and fused together, enabling the efficient distribution of air throughout a structure. By employing steel sheets, the ducts can endure the elevated temperatures and pressures associated with HVAC systems, all while retaining their structural integrity. Furthermore, steel ducts exhibit increased resistance to harm caused by pests, moisture, and the growth of mold when compared to alternative materials. In summary, the reliability and capacity to meet the requisite performance standards make steel sheets a fitting choice for the production of HVAC ducts.

Send your message to us

Hot Rolled Plate Steel 2016 New Desigh Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords