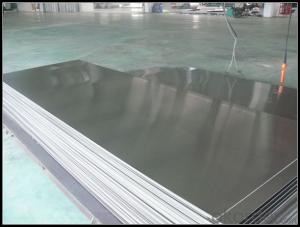

Coiled Aluminum Sheet 1.8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

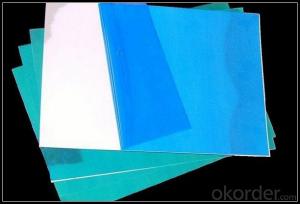

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

- Q: Can aluminum coils be used in the manufacturing of appliances?

- Indeed, the utilization of aluminum coils in appliance manufacturing is possible. Aluminum, renowned for its lightweight and robust nature, is frequently employed in the manufacturing sector due to its exceptional thermal conductivity and ability to resist corrosion. Such attributes render it suitable for an array of applications, including the creation of heating and cooling systems found in appliances like refrigerators, air conditioners, and ovens. In these appliances, aluminum coils are frequently employed to facilitate efficient heat transfer and guarantee optimal functionality. Furthermore, aluminum represents a sustainable option as it is eminently recyclable, thus presenting appliance manufacturers with an environmentally conscious choice.

- Q: Can aluminum coils be used in automotive heat exchangers?

- Indeed, automotive heat exchangers can utilize aluminum coils. The automotive industry favors aluminum for heat exchangers due to its exceptional thermal conductivity, lightweight quality, and resistance against corrosion. These attributes enable aluminum coils to effectively transfer heat between fluids or gases, rendering them highly suitable for automotive heat exchangers. Furthermore, aluminum coils are easily manufacturable and can be molded into diverse shapes and sizes, thereby further enhancing their appropriateness for automotive applications.

- Q: What are the different types of aluminum alloy used in coil production?

- There are several different types of aluminum alloy used in coil production, each with its own unique properties and characteristics. Some of the most commonly used aluminum alloys in coil production include: 1. 1100 Aluminum Alloy: This type of alloy is known for its excellent corrosion resistance and high thermal and electrical conductivity. It is often used in applications where strength is not a primary concern, such as in food and beverage packaging. 2. 3003 Aluminum Alloy: This alloy is commonly used in coil production due to its moderate strength and good formability. It is often used in roofing and siding applications, as well as in the manufacture of HVAC components. 3. 5052 Aluminum Alloy: This alloy is known for its high strength and excellent corrosion resistance, making it ideal for use in marine and automotive applications. It also has good formability and is often used in the production of fuel tanks and body panels. 4. 6061 Aluminum Alloy: This alloy is a versatile and widely used aluminum alloy that offers a good balance of strength, formability, and corrosion resistance. It is commonly used in a variety of applications, including structural components, automotive parts, and aerospace components. 5. 7075 Aluminum Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is often used in applications where strength and durability are critical, such as in the aerospace industry. These are just a few examples of the different types of aluminum alloys used in coil production. Each alloy has its own unique properties that make it suitable for specific applications, and manufacturers choose the appropriate alloy based on the desired characteristics of the final product.

- Q: How are aluminum coils used in the production of cookware?

- Aluminum coils are used in the production of cookware as they are rolled into thin sheets and then formed into various shapes like pots, pans, and trays. These coils are lightweight, conduct heat efficiently, and have excellent heat distribution properties, making them ideal for cookware manufacturing. Additionally, aluminum's non-reactive nature ensures that it does not alter the taste or quality of the food being cooked.

- Q: Are aluminum coils suitable for electrical insulation?

- No, aluminum coils are not suitable for electrical insulation. Aluminum is a good conductor of electricity, meaning it allows the flow of electric current rather than resisting it. In electrical systems, insulation is needed to prevent the flow of electricity and protect against short circuits or electrical shock. Materials such as rubber, plastic, or ceramic are commonly used for electrical insulation due to their high resistance to electric current.

- Q: Is it possible to utilize a press machine to bend aluminum coils?

- <p>Yes, you can use a press to bend aluminum coils. Presses are versatile machines capable of bending various materials, including aluminum. However, it's crucial to select the appropriate press type and size for the specific coil dimensions and desired bend. Additionally, ensure the press has the necessary tonnage to handle the bending force required for aluminum. Using the right dies and lubrication can also improve the bending process and prevent damage to the coils. Always follow safety guidelines and consult with equipment specifications to ensure the press is suitable for bending aluminum.</p>

- Q: This question asks about the impact of aluminum coils on the quality of food when it is stored. It seeks to understand if there are any changes in the food's properties due to the presence of aluminum coils.

- <p>Aluminum coils themselves do not directly affect the quality of food during storage. They are often used in the packaging industry for their excellent barrier properties against light, oxygen, and moisture, which can help preserve the freshness and quality of food by preventing spoilage and oxidation. However, it's important to note that aluminum does not interact with food in a way that alters its taste or nutritional content. Any potential health concerns related to aluminum exposure are more associated with the manufacturing process and not with the storage of food in aluminum-coiled packaging.</p>

- Q: How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

- Q: Can aluminum coils be used in marine applications?

- Yes, aluminum coils can be used in marine applications. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is commonly used in the construction of boats, ships, and other marine structures. Aluminum coils are particularly useful in marine applications as they can be easily formed into various shapes and sizes, making them suitable for different parts and components in the marine industry. Additionally, aluminum coils can withstand harsh marine environments and are highly resistant to saltwater corrosion, which is a significant concern in marine applications. Overall, the use of aluminum coils in marine applications is a reliable and effective choice.

- Q: What are the different protective film options for aluminum coils?

- Some different protective film options for aluminum coils include polyethylene films, polyvinyl chloride (PVC) films, and polypropylene films. These films are designed to provide temporary protection during transportation, handling, and storage, preventing scratches, abrasions, and other damages. The choice of protective film depends on factors such as the specific application, environmental conditions, and desired level of protection.

Send your message to us

Coiled Aluminum Sheet 1.8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords