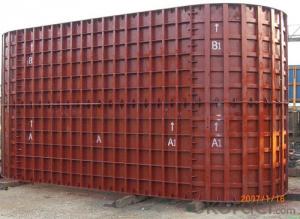

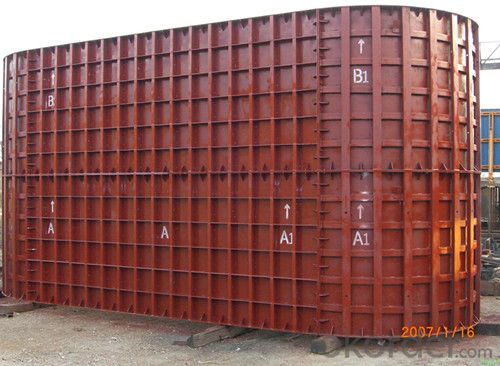

CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: How does steel formwork contribute to the overall fire safety of the building?

- Steel formwork contributes to the overall fire safety of the building in several ways. Firstly, steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. This helps to minimize the risk of fire spread and containment breaches within the structure. Additionally, steel formwork provides structural stability and strength, which is crucial during a fire event as it helps to maintain the integrity of the building and prevents structural collapse. Steel also has a high melting point, allowing it to withstand high temperatures for longer periods before it weakens, providing additional time for evacuation and firefighting efforts. Overall, the use of steel formwork enhances the fire resistance of the building, ensuring the safety of occupants and minimizing potential damage.

- Q: How long does steel formwork last?

- Various factors, including the quality of the steel used, the frequency and type of usage, and the maintenance practices employed, can affect the lifespan of steel formwork. Typically, steel formwork is renowned for its durability and longevity, and with proper maintenance, it can endure for numerous years or even decades. When steel formwork is consistently maintained and handled correctly, it can endure multiple uses and continue to function effectively. However, it is important to acknowledge that over time, steel formwork may experience wear and tear due to constant exposure to concrete, which can result in surface corrosion or deterioration. To address this, protective coatings can be applied or the formwork can be cleaned after each use. Moreover, external factors like environmental conditions and the type of concrete used can also impact the lifespan of steel formwork. Exposure to harsh weather conditions or chemicals can expedite the corrosion process, potentially reducing the formwork's lifespan. To ensure the durability of steel formwork, it is crucial to invest in high-quality steel with proper anti-corrosion properties, conduct regular inspections, and perform necessary maintenance and repairs as required. By adhering to these practices, steel formwork can endure for a significant period, making it a cost-effective and dependable choice for construction projects.

- Q: Is steel formwork suitable for projects with limited access?

- Yes, steel formwork can be suitable for projects with limited access. Steel formwork is known for its high strength and durability, allowing it to withstand the challenges of a project with limited access. It can be easily transported and assembled in confined spaces, making it a favorable choice for projects where access is restricted. Additionally, steel formwork can be easily dismantled and reused, which is beneficial in limited access situations where materials need to be transported in and out efficiently. The flexibility and adaptability of steel formwork make it a viable option for projects with restricted access.

- Q: How is steel formwork removed after concrete has cured?

- Steel formwork is typically removed after the concrete has cured by using tools such as hammers, pry bars, or mechanical devices like formwork stripping systems. The formwork is carefully dismantled in a systematic manner, starting from the top and working downwards. The process involves loosening the connections, releasing any clamps or wedges, and gently removing the formwork panels or frames. Care is taken to ensure that the concrete structure remains intact and undamaged during the removal process.

- Q: Can steel formwork be used for circular columns?

- Yes, steel formwork can be used for circular columns. Steel formwork is a versatile and flexible option that can be easily adjusted to different shapes and sizes, including circular columns. Its strength and durability make it suitable for creating precise and stable concrete structures, even with complex geometries like circular columns.

- Q: Can steel formwork be used for shopping mall construction projects?

- Yes, steel formwork can be used for shopping mall construction projects. Steel formwork is a popular choice for construction projects due to its durability, strength, and versatility. It provides a strong and rigid structure that can withstand the pressures of a shopping mall construction project. Additionally, steel formwork allows for easy customization and modification, which is beneficial when constructing complex structures like shopping malls. Moreover, steel formwork offers a smooth and high-quality finish, ensuring that the final result meets the aesthetic requirements of a shopping mall. Overall, steel formwork is a suitable option for shopping mall construction projects due to its strength, durability, versatility, and aesthetic appeal.

- Q: What are the different accessories required for steel formwork maintenance?

- The different accessories required for steel formwork maintenance include the following: 1. Formwork cleaning agents: These are used to remove any concrete residue or build-up on the steel formwork. They help in maintaining the smooth surface of the formwork and prevent any damage or corrosion. 2. Formwork release agents: These are applied to the steel formwork before pouring concrete to prevent it from sticking to the formwork. They help in easy removal of the formwork after the concrete has cured. 3. Formwork patching compounds: These are used to repair any damages or imperfections on the steel formwork. They help in maintaining the structural integrity of the formwork and ensure its longevity. 4. Formwork oil or grease: These lubricants are applied to the moving parts of the steel formwork, such as hinges or sliding mechanisms. They help in smooth operation and prevent any friction or wear and tear. 5. Formwork ties and connectors: These are used to secure the formwork panels together and ensure stability during concrete pouring. They should be regularly inspected and replaced if damaged or worn out. 6. Formwork wedges and pins: These are used to align and secure the formwork panels in place. They should be checked regularly to ensure proper positioning and stability. 7. Formwork clamps and brackets: These accessories are used to support and hold the formwork panels in position. They should be inspected for any signs of damage or weakness and replaced if necessary. 8. Formwork cleaning tools: These include brushes, scrapers, and high-pressure washers, which are used to clean the steel formwork. Regular cleaning helps in maintaining the formwork's appearance and prevents the accumulation of dirt or debris. 9. Formwork storage and transportation equipment: These include racks, trolleys, or storage containers, which are used to store and transport the steel formwork safely. Proper storage and transportation ensure the formwork's longevity and prevent any damage or distortion. Overall, the different accessories required for steel formwork maintenance are crucial to ensure the formwork's optimal performance, durability, and safety during concrete construction projects.

- Q: How does steel formwork contribute to better site organization?

- Steel formwork contributes to better site organization in several ways. Firstly, steel formwork is highly durable and reusable, which means it can be used multiple times on different construction projects. This eliminates the need for frequent replacement and reduces waste on site. The ability to reuse steel formwork also reduces storage space requirements, as it can be easily stacked and stored when not in use. Secondly, steel formwork is adjustable and customizable, allowing it to be easily modified to fit different shapes and sizes of concrete structures. This flexibility enables efficient use of space on site, as the formwork can be tailored to the specific requirements of each project. This ensures that the construction process is organized and streamlined, minimizing the need for additional materials or adjustments. Furthermore, steel formwork is known for its high strength and stability, which enhances site safety. Its robust structure provides a secure platform for workers to carry out their tasks, reducing the risk of accidents or injuries. This promotes a safer working environment and improves overall site organization. Steel formwork also contributes to better site organization by facilitating faster construction cycles. Its quick assembly and disassembly process allows for efficient and smooth workflow, enabling construction projects to be completed in a timely manner. This helps to minimize delays and ensures that the site is well-organized and productive. Lastly, steel formwork can be easily integrated with other construction systems and technologies. This compatibility allows for seamless coordination between different components of the project, promoting better site organization. Whether it is integrating with scaffolding systems or connecting to other structural elements, steel formwork ensures a cohesive and well-organized construction site. In conclusion, steel formwork contributes to better site organization through its durability, adjustability, strength, and compatibility with other construction systems. Its ability to be reused, customized, and integrated with other components enhances efficiency, safety, and productivity on construction sites.

- Q: How does steel formwork affect the overall quality of the concrete structure?

- Steel formwork plays a crucial role in determining the overall quality of a concrete structure. It affects the quality in several ways: 1. Dimensional Accuracy: Steel formwork ensures precise and accurate dimensions of the concrete structure. It provides a rigid framework that holds the concrete in shape during the pouring and curing process, preventing any deformation or distortion. This accuracy in dimensions contributes to the overall strength, stability, and durability of the structure. 2. Surface Finish: Steel formwork helps achieve a smooth and uniform surface finish of the concrete. The smoothness of the formwork translates into a smooth concrete surface, reducing the need for additional finishing work. A smooth surface not only enhances the aesthetic appeal but also improves the durability and resistance to wear and tear. 3. Strength and Load-bearing Capacity: Steel formwork is known for its high strength and load-bearing capacity. This strength allows it to withstand the pressure exerted by the concrete during pouring and curing. A sturdy formwork ensures that the concrete structure is adequately supported and can withstand the loads it is designed to bear. This contributes to the overall structural integrity and safety of the building. 4. Reusability and Cost-effectiveness: Steel formwork is reusable, making it a cost-effective option in the long run. Its durability allows it to withstand multiple uses, reducing the need for frequent replacements. This not only saves money but also reduces waste generated during construction. By using steel formwork, contractors can achieve high-quality concrete structures without compromising on cost or environmental impact. In conclusion, steel formwork greatly influences the overall quality of a concrete structure by providing dimensional accuracy, smooth surface finish, strength, load-bearing capacity, reusability, and cost-effectiveness. Its proper use ensures that the structure meets the required standards, enhances its durability, and ensures the safety of occupants.

- Q: How does steel formwork handle architectural features such as openings and recesses?

- Steel formwork is a versatile construction material that can effectively handle architectural features such as openings and recesses. Its strength and flexibility make it ideal for accommodating these design elements in concrete structures. When it comes to openings, such as windows or doors, steel formwork can be easily customized to create precise and well-defined openings. The formwork panels can be cut or shaped to the desired size and shape, allowing for accurate placement of the concrete around the opening. Steel formwork also provides stability and support during the pouring and curing process, ensuring that the concrete around the opening remains structurally sound. Recesses, on the other hand, can be easily formed using steel panels that are specifically designed to create the desired recessed area. These panels can be shaped or molded to match the architectural design, providing a seamless integration of recesses into the concrete structure. Steel formwork enables precise control over the depth and dimensions of the recess, ensuring that it meets the design requirements. In addition to its adaptability, steel formwork also offers several benefits when handling architectural features. Its durability and resistance to deformation allow it to withstand the pressure exerted by the concrete, ensuring that the formwork remains in shape throughout the construction process. This is crucial for maintaining the accuracy and integrity of architectural features. Furthermore, steel formwork is reusable, making it a cost-effective option for projects that involve multiple openings and recesses. The panels can be disassembled, cleaned, and reassembled for future use, reducing the need for new formwork materials and minimizing waste. Overall, steel formwork is a reliable and efficient choice for handling architectural features such as openings and recesses. Its strength, flexibility, and reusability make it an ideal construction material for creating precise and visually appealing architectural designs.

Send your message to us

CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches