Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear

edge: flat edge,grind edge,finepolished edge,bevelled edge

Packaging & Delivery of Double Tempered Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: 7-15 days

Specifications of Double Tempered Laminated Glass

1 Safety

2 Strength for resistance to impact

3 Strength for resistance to human body5 Sound insulation

1) safety

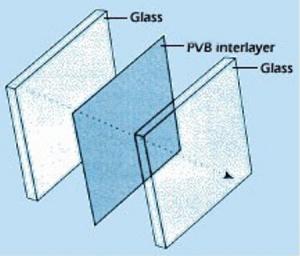

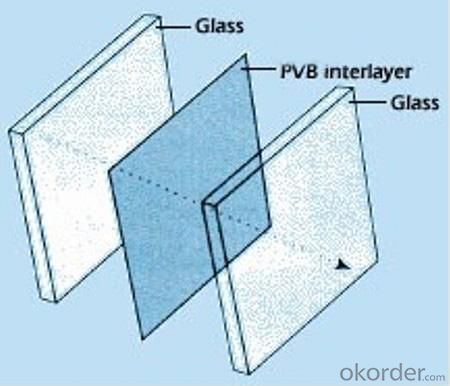

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

4)application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Specification of Double Tempered Laminated Glass

The color of PVB

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Laminated Glass Performance Levels according to Thickness

Glass Characteristic |

Thickness (mm) |

UV Transmittance (%) |

LT (%) |

3+0.38+3mm Clear |

6.38mm |

5 |

89 |

6+0.38+6mm Clear |

12.38mm |

3 |

86 |

6+0.38+6mm Reflective |

12.38mm |

0.5 |

22 |

- Q: Glass raw materials processing equipment, glass raw materials crushing equipment prices generally sell how much?

- 1. coarse crushing jaw crusher, 2. cone crusher, 3. sand machine, 4. screening machine, 5. finished products

- Q: What are the aluminum films used in glass processing enterprises?

- The raw materials of various raw materials products mainly refers to the business entities and in the production process by the process to change its form or nature and main materials, auxiliary materials, fuel, spare parts for repair (spare parts), packaging materials, semi-finished product outsourcing (outsourcing) etc.. The aluminum film in question is one of the main materials used in glass processing.

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- High quality glass steel products appearance has no obvious cracks, pores are less pure, bright color, good transparency, toughness has a certain strength, good surface smoothness, long service life; while the poor quality of the glass steel product surface crack, more pores, mixed color gloss is not enough. Its service life is also short.

- Q: The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q: Raw material, processing method and ratio of glass fiber reinforced plastic

- Processing method:Basically divided into two major categories, namely wet contact and dry pressing molding. According to the characteristics of the process, there are hand molding, laminating, RTM, extrusion, molding, winding and so on. Hand molding also includes hand paste method, bag pressure method, spray method, wet paste low pressure method and no mold hand paste method.

- Q: Tempered and reinforced glass

- Enterprises producing safety glass must pass compulsory certification by the state, otherwise they are not allowed to appear on the market. Therefore, toughened glass has the following signs:Tempered glass, if made into reinforced glass, is substandard products.10mm toughened glass generally costs less than 100 yuan. Paint and not much money, but if the price is higher glaze.

- Q: What is acrylic material?

- Acrylic production process;Acrylic sheet according to the production process can be divided into casting and extrusion, better than the properties of casting sheet extrusion, the price is expensive, the plate casting is mainly used for carving, decoration, arts and crafts, extrusion type is usually used for advertising signs, light boxes and other production.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

- Q: What is the glass industry?

- The glass belongs to the chemical industry, glass production process mainly includes: raw material processed. The massive raw materials (quartz sand, soda ash, limestone, feldspar) grinding, wet material drying, iron containing raw materials for iron removal treatment, in order to ensure the quality of glass batch preparation. 2. The melting of glass batch. High temperature in the furnace or crucible kiln (1550~1600) heating, so as to form uniform, no bubbles, and meet the requirements of molding liquid glass.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords